Initiatives to Support a Circular Economy

Ecology [Building a circular economy]

- E ●

- S -

- G -

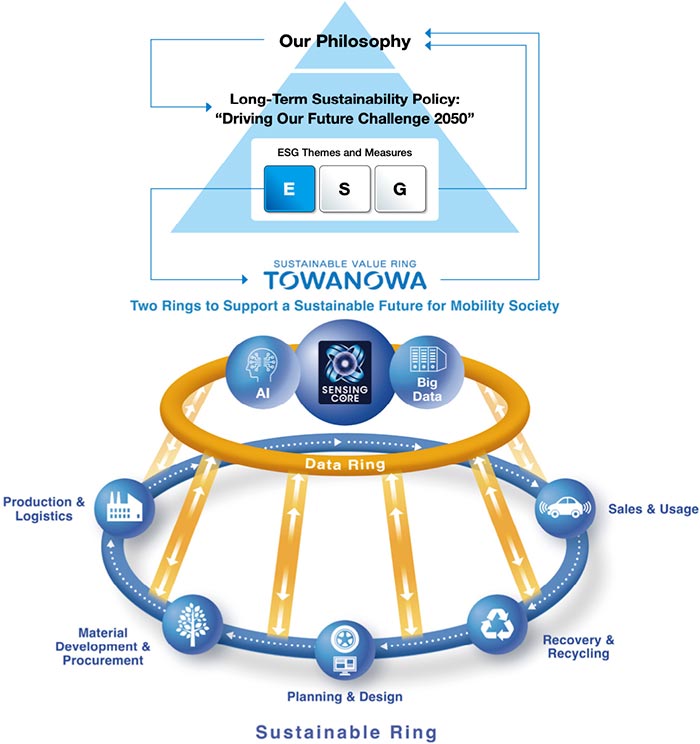

Overview of “TOWANOWA,” a Business Model Designed to Support a Circular Economy through the Tire Business

- The Sumitomo Rubber Group

Encapsulating our hope to support the long-lasting development of a sustainable mobility society in the future, the word TOWANOWA brings together the two Japanese terms TOWA, meaning “Everlasting,” and WA, meaning “Ring.”

In line with the TOWANOWA concept, we aim to facilitate the circulation and effective utilization of limited resources while promoting the use of big data, comprising data gleaned by such technologies as SENSING CORE, an asset unique to the Sumitomo Rubber Group. Through these efforts, we will deliver new value to customers, contribute to the creation of the next-generation mobility society and otherwise help realize a sustainable future in which all people can enjoy safety, security and comfort. We will thus promote the TOWANOWA concept to realize a long-lasting tire business cycle as part of efforts to embody “Our Philosophy.” In the course of doing so, we will address issues associated with CASE* megatrends, help realize a sustainable world and contribute to the creation of a future of joy and well-being for all.

*“CASE” is regularly used to describe the four main strategic areas of focus for the industry—an abbreviation for Connected, Autonomous, Shared and Electrified.

Click here for the detail of “TOWANOWA” (Japanese only)

The TOWANOWA concept is best illustrated as a structure in which a “data ring” (here depicted in orange) and a “sustainable ring (in blue) work in unison. While the data ring coordinates and leverages data obtained in each value chain process (“Planning & Design,” “Material Development & Procurement,” “Production & Logistics,” “Sales & Usage” and “Recovery & Recycling”), the sustainable ring facilitates the circulation of goods and materials throughout the value chain processes, eliminates redundant resource consumption and helps realize a circular economy. TOWANOWA is thus aimed at creating new value.

Our Sustainable Product Certification System (Internal Standards)

In 2023, the Sumitomo Rubber Group introduced a certification system for sustainable products based on internal standards as part of measures specified in its Long-Term Sustainability Policy “Driving Our Future Challenge 2050.”

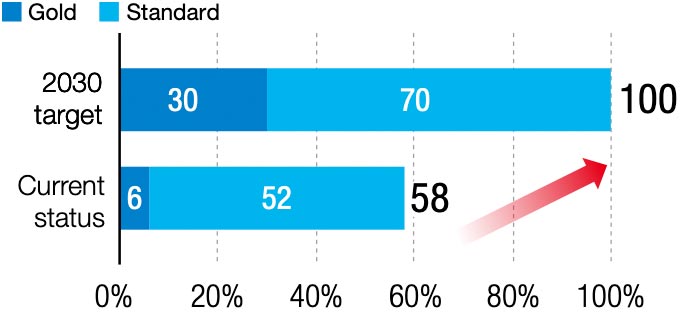

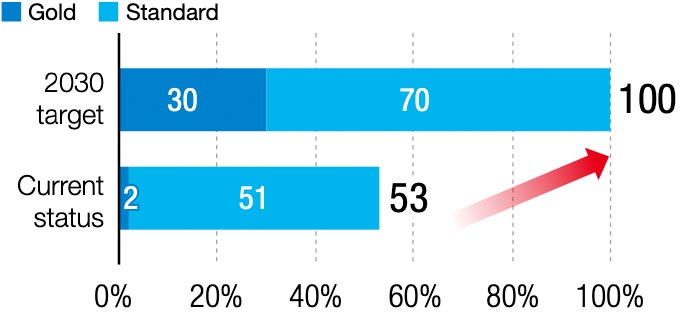

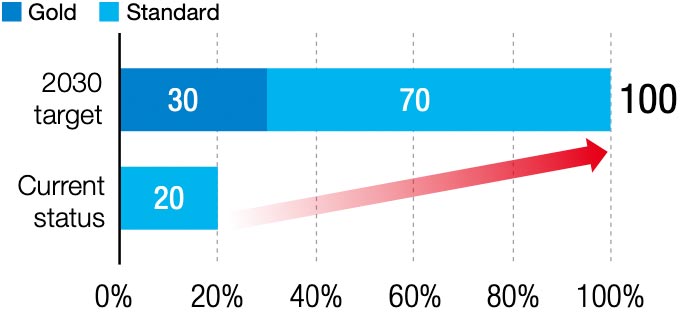

We thus apply our own assessment standards to the selection and certification of sustainable products from among all offerings of our Tire, Sports, Industrial Products and other businesses. Assessment items are set for each product group and include the ratio of sustainable raw materials used, the type of energy consumed in manufacturing processes and the product’s recyclability after use. Products that meet bare minimum requirements are designated “Standard,” while “Gold” certification is granted only to products boasting outstanding features in terms of sustainability. Our current aim is to ensure that all products are certified “Standard” by 2030 and, to this end, are striving to update their features. Looking ahead, we will continue to develop an internal certification framework to identify products capable of contributing to global warming countermeasures and environmental load reductions throughout their life cycles. By doing so, we will align our product development approach with a progressive shift to a business model in favor of circular economies.

The Current Ratio of Internally Certified Products and Our Target for 2030 Regarding This Ratio

Ratio of Certified Tires (based on units of tires)

Ratio of Certified Sports Business Offerings (based on sales)

Ratio of Certified Industrial Products Business Offerings (based on the number of sites)

We aim to ensure that all products acquire “Standard” certification or above by 2030.

Examples of Assessment Standards

| Phase | Assessment items | Examples of initiatives deemed worthy of certification |

|---|---|---|

| Planning and design | Lightweight | Promote weight saving for tire products to curb CO2 emissions in the course of use Save resources by reducing packaging material use, curb CO2 emissions in the course of transportation, cut back on the volume of waste plastics, etc. |

| Material development and procurement | Materials | Increase the ratio of sustainable raw materials used (adoption of biomass or recycled raw materials) |

| Production and distribution | Energy | Increase the ratio of renewable energy used in the course of manufacturing Reduce the overall volume of energy used in the course of manufacturing, etc. |

| Sales and use | Fuel efficiency | Decrease tires’ rolling resistance to reduce environmental burden |

| Product life | Improve tires’ wear resistance to reduce environmental burden | |

| Recovery and recycling | Specifications | Enhance the ease of retreading Adopt product labeling designed to indicate environmental friendliness and raise public environmental awareness Adopt resource-saving installation methods for industrial products |

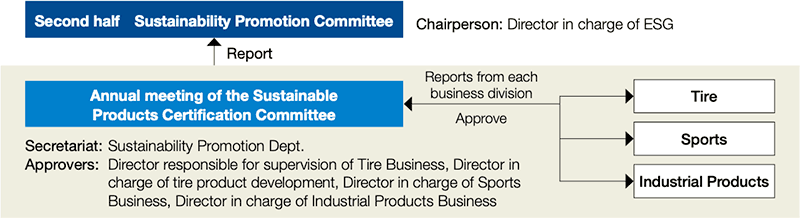

The following diagram shows the flow of our certification scheme. First, separate product development committees are convened to examine Tire, Sports and Industrial Products business offerings to determine candidate products. Directors then screen these products at the annual meeting of the Sustainable Products Certification Committee to finalize those worthy of certification. Through this scheme, we will promote the development of an internal structure for incorporating sustainability elements into product development.

Certification Scheme