Sumitomo Rubber Develops “Tire Aerodynamic Simulation" ~Essential for Development of Next-Generation EV Tires: Contributing to Elucidating Aerodynamic Characteristics of Tires that Account for Over 20% of Air Resistance of EV~

Feb. 07. 2024

Sumitomo Rubber Industries, Ltd. is pleased to announce the development of a new simulation technique called "Tire Aerodynamic Simulation," which is used in the process of tire development. In order to reduce the fuel (electricity) consumption of electric vehicles (EVs), it is very important to minimize tire rolling resistance as well as air resistance around the tire. We will pursue the development of a tire shape that optimizes aerodynamic performance by visualizing the airflow around the tire of a running vehicle through our own simulation using AI, and thereby aim to develop a tire that further contributes to lowering the electricity consumption of an EV in a next-generation EV tire to be launched in 2027.

|

||

| Visualize the airflow around the tire through the simulation technique | Calculate the aerodynamics of a rotating tire, including the tire pattern and changes in the tire shape in contact with the surface |

|

|

| Sidewall aerodynamic simulation that can accommodate the lettering and fine texture on the sidewall |

As performance required of an EV tire, one important element is to achieve low electricity consumption in order to maximize the range . In addition to various measures we have already taken to reduce tire rolling resistance, we will focus on decreasing air resistance, which is important to lower the electricity consumption of an EV tire. Our recently developed simulation technology, "Tire Aerodynamic Simulation," will help us to accomplish this goal.

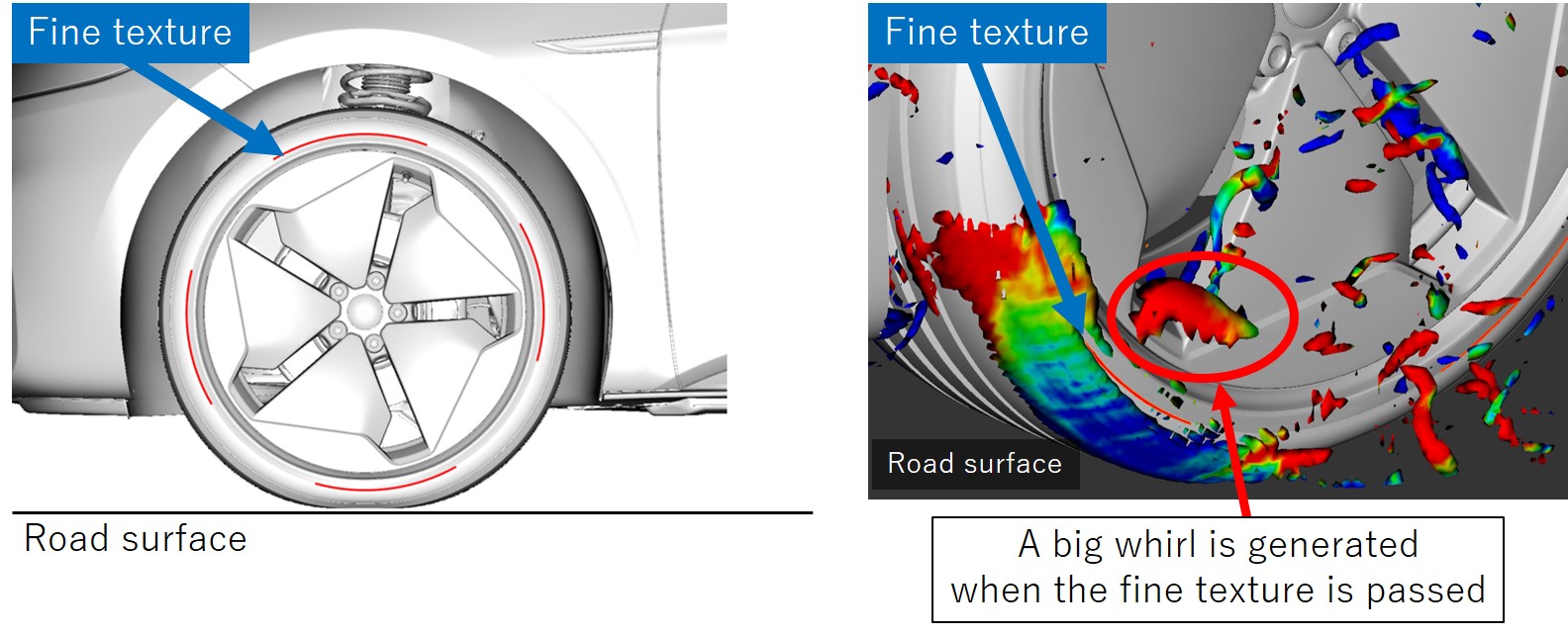

With a rapid shift to EVs occurring today, the impact of air resistance is becoming increasingly important. Unlike internal combustion engine (ICE) vehicles, which lose over 50% of their energy due to heat, EVs suffer much less energy loss from heat. This means that air resistance accounts for a larger portion of total energy loss in EVs. The tires are exposed to the outside of the vehicle body, and the air that passes around the tires flows out to the underside and side of the vehicle; as a result, 20% to 25% of the energy loss due to air resistance in a passenger car is related to the tires. In EVs, which cause almost no energy loss due to heat, around 34% to 37% of the energy loss is attributed to the tires, if rolling resistance is included.*1

|

| Comparison of energy loss at a speed of 100 kilometers per hour between ICE vehicle and EV |

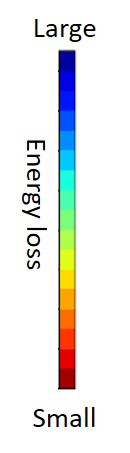

The newly developed “Tire Aerodynamic Simulation” is a simulation technique that allows us to visualize air resistance around a tire. It uses actual vehicle data to calculate the aerodynamics of a rotating tire while simulating the tire pattern and analyzing results through the use of AI technology. The simulation technique accounts for the effect of tire deflection due to vehicle weight. In addition, we have newly developed a simulation technique that changes the shapes of the lettering and fine texture on the sidewall while they are rotating in the same way as the pattern. While it is important to smoothen the sidewall to reduce air resistance in EVs, using the newly developed simulation technique will enable the development of a tire that achieves both design and aerodynamic performance at higher levels.

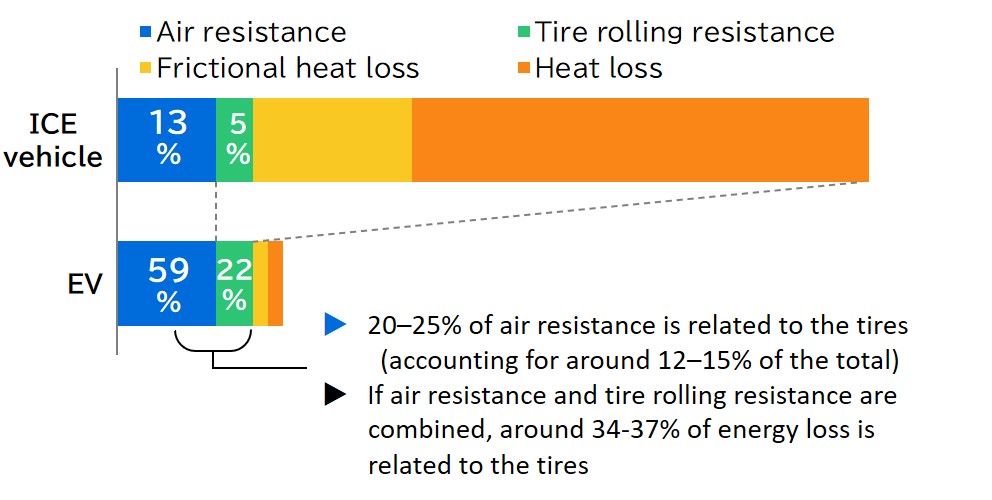

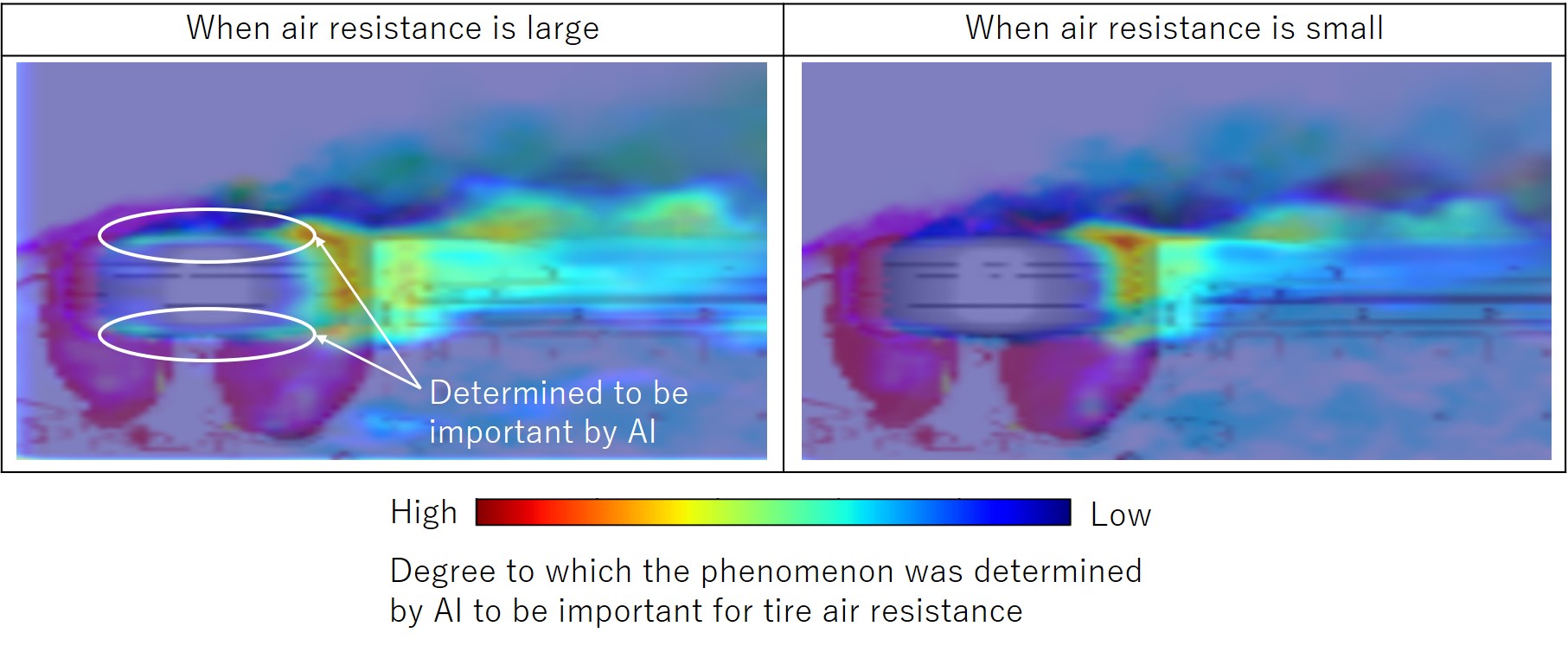

In comparison with the results of a wind tunnel experiment, which was conducted with an actual vehicle to confirm the accuracy of the simulation, the EV tire with a decreased airflow trend behind the tire and less unevenness on the sidewall showed lower air resistance values than the standard tire. This confirmed the potential of the newly developed simulation technique. Furthermore, the AI technology used in the simulation suggests that the sidewall plays a crucial role in air resistance reduction when the air resistance is high, offering additional evidence of the effectiveness of the technology. Adopting this technique yields improved tire performance with maximized aerodynamic characteristics, leading to reduced aerodynamic drag and electricity consumption for an EV.

|

| Comparison of variations of air resistance values between actual vehicle and simulation |

|

| Example of the results of visualization of important positions for tire air resistance through AI |

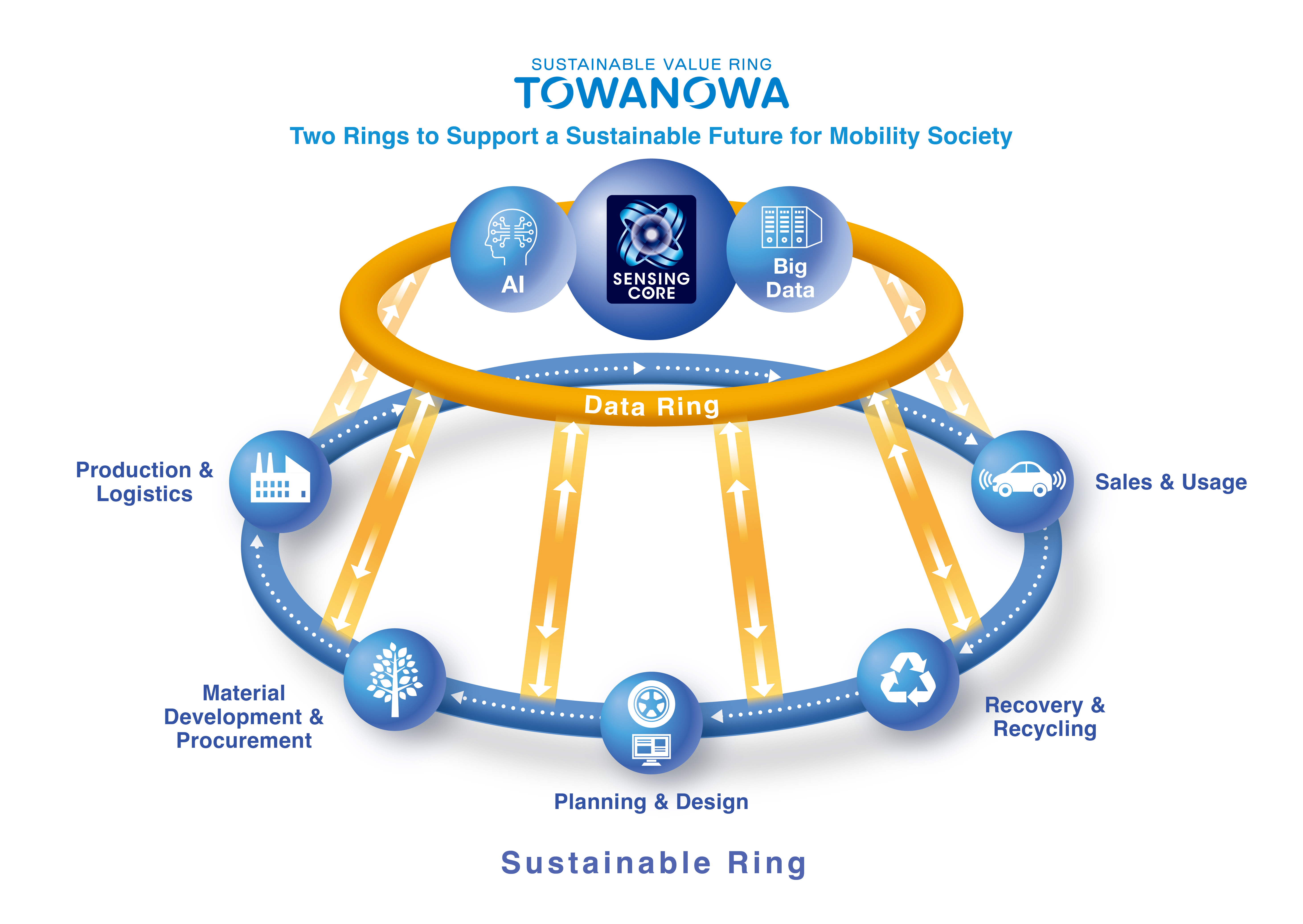

We unveiled our own unique Circular Economy Concept for the Tire Industry, which we call TOWANOWA,*2 in March 2023. TOWANOWA features a two-ring structure, with a “Sustainable Ring” consisting of five processes in the value chain and a “Data Ring” linking big data collected from each process. We aim to provide new value by sharing / using data between the two rings.

The newly developed Tire Aerodynamic Simulation technique will use simulation data obtained through the “Planning & Design” process to reduce air resistance when the vehicle is running, and thereby help lower the electricity consumption in EVs.

Through TOWANOWA, the Sumitomo Rubber Group will further accelerate our efforts to promote and practice ESG Management, and contribute to the achievement of carbon neutrality by 2050 and the development of a sustainable society.

|

|

Conceptual diagram of Circular Economy Concept TOWANOWA

|

※1 Data cited from "Improvement of Practical Electric Consumption by Drag Reducing under Cross Wind", Kawamata, Hideyuki; Kuroda, Satoru; Tanaka, Shingo; Oshima, Munehiko, SAE technical paper series, (2016)