With the advent of CASE (Connected , Autonomous, Shared & Services , Electric) and MaaS (Mobility as a Service) and the subsequent rise of car sharing, ride sharing and other new types of mobility services, we are increasingly seeing a shift in the role that automobiles play in our society: transitioning away from being an asset that is owned and toward becoming a tool that is used. As a consequence of this transformation of the automotive industry, we are now also seeing some major changes in the functional and performance requirements of tires.

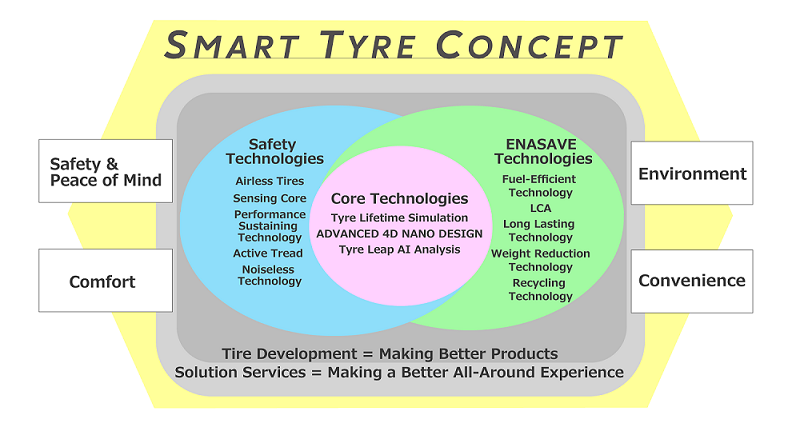

In light of these recent trends and with an eye toward the Mobility Society of the Future, the Sumitomo Rubber Group is actively pushing ahead with research and development under our SMART TYRE CONCEPT with the aim of developing tires and peripheral services that provide greater performance than ever before when it comes to Safety and the Environment.

SMART TYRE CONCEPT is a catchall term for our ongoing efforts to develop the various technologies that we will need to create the tires of the future, such as “tires that respond to the needs of autonomous vehicles,” “tires that provide solutions for greater safety and peace of mind,” “tires that incorporate the concept of Life Cycle Assessment (LCA)” and so forth.

The Sumitomo Rubber Group has already made significant progress in developing products that incorporate SMART TYRE CONCEPT technologies, including “Performance Sustaining Technology,” which inhibits the deterioration of tire performance due to wear and rubber degradation over time so that tires can maintain like-new performance for longer, as well as “Life Cycle Assessment,” which improves environmental performance throughout the entire life cycle of a tire so that tires can contribute to the realization of a recycling-oriented society. At the same time, we are also pushing ahead with the development of new solutions services that take advantage of a wide range of data accumulated using various innovative digital tools.

SMART TYRE CONCEPT Overview

Combining extensive knowhow on the dynamic behavior of tires gained through our many years of developing cutting-edge tires with advanced digital filtering technology that analyzes and interprets the wheel speed signals generated by tire rotation, SENSING CORE is a proprietary technology that is able to detect various tire and road conditions , including tire pressure, wear progression and load as well as the slipperiness of the road itself.

This same type of technology has already found practical applications in the form of our “Deflation Warning System (DWS),” which detects any decrease in tire pressure and promptly alerts the driver. DWS has been installed in countless vehicles to date. With SENSING CORE, we will further expand the capabilities of this system to analyze and interpret a broader range of data concerning both tire and road conditions, utilizing this data not only for optimized vehicle control, but also for more in-depth analysis of Big Data accumulated through the cloud from vehicles throughout a whole city or even an entire society. The results of this analysis will then be provided back to vehicles as a constant stream of feedback so that vehicles can actively detect and avoid potential hazards related to tire or road conditions before they even arise. What sets SENSING CORE apart is the fact that this technology uses tires themselves as sensors, meaning that it requires no additional sensors or other hardware installation and is completely maintenance-free.

SENSING CORE

On April 22, 2022, we held a "SENSING CORE Technology Future Concept Press Event."

At this event, we introduced our recent efforts to bring new applications and expanded functionality to our SENSING CORE Technology and explained our Future Business Concept for this innovative technology.

April 22, 2022 “SENSING CORE Technology Future Concept Press Event”(PDF 4,464.1KB)

With the transition to autonomous vehicles, the role that humans play in ensuring safe transportation will shrink as vehicles themselves take on a wider range of responsibilities in this regard. As tires are the only part of a vehicle that comes into direct contact with the road, the Sumitomo Rubber Group is working to establish a new technology that responds to changes in road conditions (such as water or ice) by actively changing the functional traits of tread rubber to optimize tire performance for the current road surface and weather conditions, thus ensuring uninterrupted safe driving and peace of mind even when faced with sudden changes in road conditions during automated driving.

Performance Sustaining Technology inhibits performance decline due to tire wear and rubber degradation over time so that tires can maintain like-new performance for longer. In developing this groundbreaking technology, we took full advantage of our proprietary “Tyre Leap AI Analysis*1” AI Technology and “ADVANCED 4D NANO DESIGN*2” New Materials Development Technology in order to shed light on the molecular-level mechanisms behind tire wear and the degradation of rubber over time.

The Sumitomo Rubber Group has already released tires (such as our “ENASAVE NEXT III” and “VEURO VE304”) that incorporate Performance Sustaining Technology in the form of “Hydrogenated Polymer,” a new rubber material that is unlike any other type of polymer used in tires before. Performance Sustaining Technology also led to the adoption of “Liquid Farnesene Rubber*3” in our “WINTER MAXX 03” studless tires, allowing these tires to maintain outstanding on-ice performance for longer thanks to this advanced material’s ability to preserve rubber suppleness over the long run.

*1. Tyre Leap AI Analysis: This cutting-edge AI technology utilizes real-world data on the raw materials of tires in combination with advanced analytical data on the actual internal structures of rubber in order to precisely estimate rubber properties. In addition, through the detection of structural changes that occur in rubber during use, this technology is also capable of predicting the properties of rubber after use.

*2. ADVANCED 4D NANO DESIGN: This groundbreaking technology allows for dynamic analysis and simulation of the internal structures of rubber with very high precision from the micron scale down to the nanometer scale.

*3. Liquid Farnesene Rubber: A new material developed specifically for our WINTER MAXX Series by KURARAY CO., LTD. Simultaneously functioning as rubber and as a softening agent, Liquid Farnesene Rubber has properties that allow it to maintain the adhesiveness and suppleness of rubber in low-temperature environments.

The Sumitomo Rubber Group is also pushing forward with research and development toward bringing to market a practical version of GYROBLADE, our brand of tires that never need to be inflated. Airless tires provide greater transportation safety and peace of mind by freeing the driver from worries about flat tires and the trouble of having to manage tire pressure.

The Sumitomo Rubber Group is actively working to develop products that contribute to the realization of a recycling-oriented society by incorporating the concept of Life Cycle Assessment (LCA) into our products with the aim of enhancing their environmental performance throughout their entire lifecycle, focusing not only on raw materials and product usage, but also on manufacturing, shipping and even recycling. We have already made great progress in promoting LCA when it comes to raw materials, including the development of the world’s first 100% fossil resource-free tires made from all-natural resources in 2013. In 2019, we followed this up with the release of “ENASAVE NEXT III,” the world’s first tires to incorporate “Cellulose Nanofiber,” a high-performance biomass material whose development and proliferation the Government of Japan is promoting as a key industry initiative.

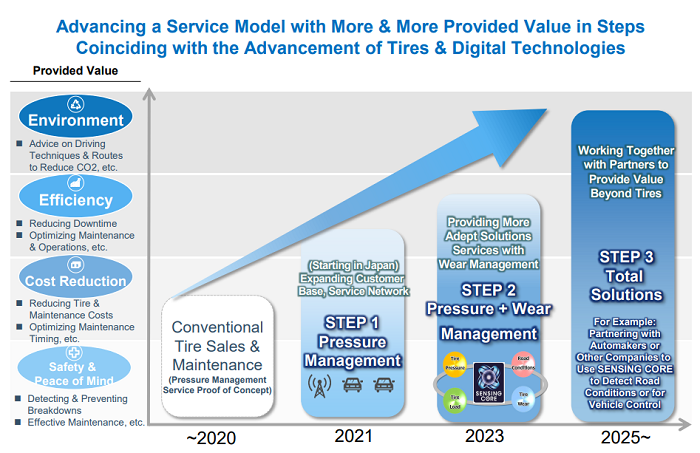

In keeping with ongoing changes to our Mobility Society, it is now becoming increasingly important to provide solutions services that meet society’s evolving needs, especially when it comes to safety and peace of mind. And so, the Sumitomo Rubber Group is now working to develop “Tire Pressure Management Solutions Services” that take full advantage of the tire pressure and temperature data gleaned from our proprietary sensor technology in order to provide new solutions for our business-to-business customers. For example, using sensors to constantly monitor tire pressure and temperature during operation will allow for smoother handling of punctures and any other tire trouble whenever it may occur across fleets of vehicles. Moving forward, we also aim to roll out a “Tire Wear Management Service” from 2023 before expanding our range of services in cooperation with our various business partners in order to provide total solutions for all things related to tires from 2025 onward.