The Sumitomo Rubber Group defines seven material issues to embody our corporate philosophy structure “Our Philosophy.” “Climate Change” is one of these issues. We have made it our vision to become “A company committed to proactively reducing CO₂ emissions,” aiming to achieve carbon neutrality by 2050. Particularly focusing on achieving carbon neutrality in manufacturing processes, harnessing hydrogen energy stands as one of our core initiatives.

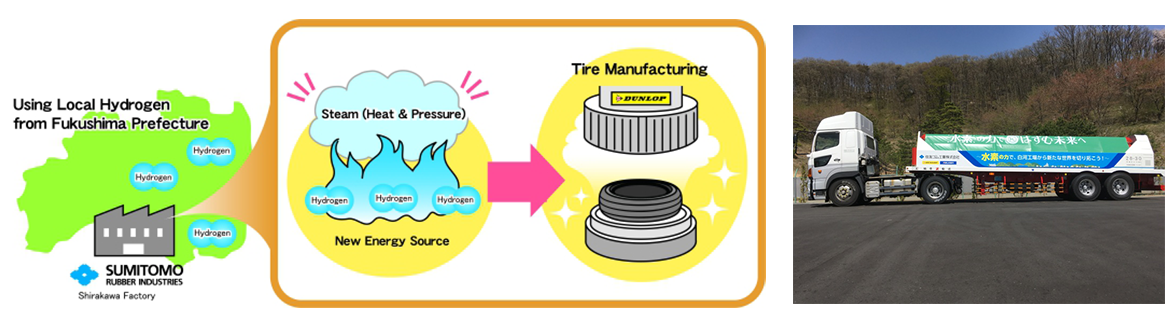

SRI has long been working on reducing CO2 emissions, through promotion of energy saving, wider use of cogeneration systems, introduction of solar power generation, and procurement of green electric power generated with renewable energy, among others. In order to achieve the carbon neutrality in the production process (Scope 1 and 2)*1, it is essential to convert into the green energy the natural gas that is currently in use for the high-temperature, high-pressure steam energy needed in the vulcanization process. In this process, the heat and pressure are applied to the tire to cause chemical reactions to make it a completed product. As it is technically difficult to use the electric power for the generation of the high-temperature, high-pressure steam, we decided to utilize “hydrogen” for the generation of the steam that burns without emission of CO2.

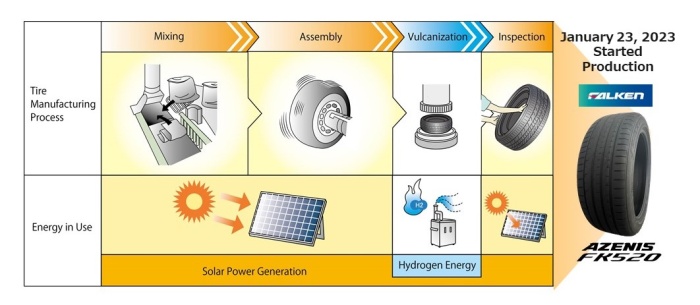

In the proof of concept, we supplies the steam, generated with the hydrogen boiler, to the high-precision metal core production system “NEO-T01”*2 during the vulcanization process. Also, we installed carport-type solar generation facilities in the parking lot for the employees that accommodates about 700 cars, which can generate more power than is used in the “NEO-T01”. We thus produces mass-production tires*3 in a way the carbon neutrality*4 (Scope 1 and 2) is achieved for the first time in Japan*5 in the production process with the use of the hydrogen energy and solar power generation.

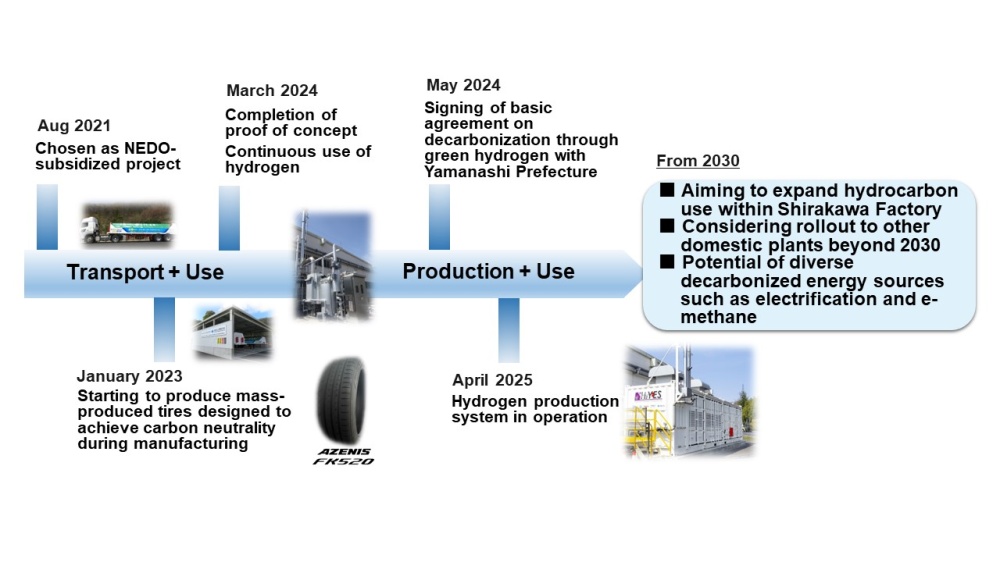

With support from the New Energy and Industrial Technology Development Organization(NEDO, a national research and development agency),we ran a proof-of-concept experiment on the use of hydrogen in tire manufacturing at our Shirakawa Factory from August 2021 to March 2024. In the demonstration, we harnessed hydrogen supplied from a hydrogen production facility in Fukushima Prefecture, a leader in renewable energy, to generate in a hydrogen boiler, high-temperature, high-pressure steam for use in the vulcanization process. In January 2023, we startd mass-production tires in a way the carbon neutrality (Scope 1 and 2) is achieved for the first time in Japan in the production process with the use of the hydrogen energy and solar power generation.

Through proof-of-concept on the use of hydrogen boilers, we identified the stable supply of green hydrogen and hydrogen costs as key challenges. To address these issues, as part of NEDO Proof-of-Concept Project*6, we started operating a hydrogen production system (Yamanashi Model P2G System) in April 2025 capable of producing hydrogen by water electrolysis using green electricity. The green hydrogen generated by the P2G system will serve as one of the five energy sources at the Shirakawa Factory, which includes delivered hydrogen, grid electricity, solar power generated on-site, and existing fuels at the Shirakawa Factory, to demonstrate a “grandmaster plant that achieves decarbonization” aimed at achieving decarbonization while maintaining stable plant operations. At the Shirakawa Factory, the P2G system runs 24 hours a day to produce up to approximately 100 tons of hydrogen annually, which is expected to reduce CO2 emissions by approximately 1,000 tons per year across the entire supply chain, including transportation (Scopes 1–3)*7.

The Yamanashi Model P2G System is a next-generation energy system developed mainly by Yamanashi Prefecture. It uses renewable energy sources such as solar power to electrolyze water in order to produce “green hydrogen”*8 with low environmental impact. As a technology that ensures stable hydrogen supply and accelerates decarbonization in a wide range of industrial fields, the P2G system attracts high expectations both in Japan and overseas.

SRI is seeking to build a local-production-for-local-consumption model of the hydrogen energy, procuring hydrogen from a hydrogen production plant in Fukushima Prefecture. Fukushima is very advanced in the field of renewable energy: more than 40% of energy consumed in the prefecture is sourced from renewables. Furthermore, it has a vision to increase the ratio to 100% by 2040. City of Shirakawa also has made the “Zero Carbon City Declaration,” planning to achieve practically zero net CO2 emissions by 2050. We will contribute to achievement of the carbon neutrality by using hydrogen produced in the region for manufacturing, thereby building the local-production-for-local-consumption model.

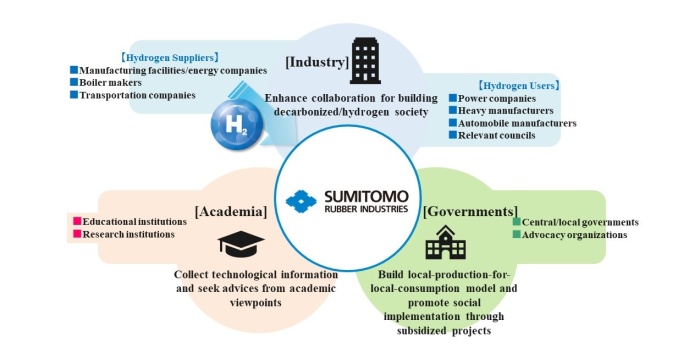

It is difficult for a single company to establish the implementation model for realization of the hydrogen society: the Sumitomo Rubber Group believes that collaboration of the relevant industries, governments and academia is essential for the success. We are already in alliance with hydrogen producers and energy companies for stable production and transportation of hydrogen, and is actively exchanging information with other relevant manufacturers. It is also collecting information from academia at various lecture sessions so that it can get advices from educational and research institutions from academic point of view. With the support from the national and local governments together with subsidy for the project, it is now planning to engage itself in communications with various parties to further enhance the collaboration among the industries, governments and academia.

We plan to put together a decarbonization strategy that looks to boost and roll out hydrogen use, as well as other decarbonized energy sources, with the goal of achieving carbon neutrality by 2050. We hope to ramp up hydrogen use at our Shirakawa Factory and will also consider rolling it out to other plants in Japan beyond 2030. Moving forward, we will explore the potential of diverse decarbonized energy sources, not just hydrogen, but electrification and e-methane.

*1 Scope 1: Direct greenhouse gas emissions from operators themselves; Scope 2: Indirect emissions associated with the use of electricity or heat supplied by other companies

*2 High-precision “Metal Core” manufacturing system that achieves balanced high performance in terms of “Riding Comfort,” “Environmental Friendliness” and “Safety” by combining three key technologies: (1) The “Metal Core Process,” in which the various components of a tire are applied one by one to a metal former (core) that has been made in the exact shape and size of an actual finished tire’s inner liner; (2) “Fully Automatic Connected Control,” which utilizes a computer control system to control the application of each tire component to the Metal Core with ultra-high precision, accurate to 0.01mm; and (3) “High-Rigidity Structure,” which allows for the use of more rigid reinforcing materials than conventional tire manufacturing techniques.

*3 FALKEN “AZENIS FK520.” Excludes FALKEN “AZENIS FK520L.

*4 Making the net emission of the greenhouse gas, including CO2, practically zero. The net emission is calculated by subtracting the volume of green gas “absorption” by means of afforestation, forest administration, etc. from that of greenhouse gas “emission.”

*5 Based on In-House Research

*6 Project for Development of Technologies for Realizing a Hydrogen Society / Regional Hydrogen Utilization Technology Development Theme: Development of technologies for Yamanashi Model for decarbonized energy network using hydrogen as heat source

*7 Scope 3: Greenhouse gases emitted by third parties that are related to the company’s activities but not directly managed by the company, such as during transportation or use and disposal after product sales

*8 Hydrogen produced with zero CO2 emissions using electricity derived from renewable energy