| |

Announcing the Development of "GYROBLADE" and "CORESEAL,"

New Tire Technologies Contributing to Improved Safety and Environmental Performance

|

| |

Sumitomo Rubber Industries, Ltd. is pleased to announce that we have developed two new tire technologies that improve safety while conserving energy and resources: our "GYROBLADE" airless tire technology means that tires never go flat because they do not need to be inflated, and our "CORESEAL" tire sealant technology prevents air leakage when a tire tread*1 is punctured.

*1 The part of a tire that is in contact with the road.

As part of our long-term vision - VISION 2020 - our company has been working on the development of environmentally friendly products under the slogan "How Tires Can Contribute to the Global Environment," with our development efforts focusing on three areas in which tires can make such a contribution: "Resource Savings," "Fuel Efficiency" and "Raw Materials." These development efforts have now resulted in two new tire technologies: "GYROBLADE" airless tire technology, which prevents flat tires from occurring in the first place, and "CORESEAL" tire sealant technology, which greatly enhance safety compared with normal tires when it comes to tire punctures. Both of these advanced technologies not only improve driving safety, but also contribute to energy and resource savings by eliminating the need for spare tires. We are planning to display prototype tires incorporating these new technologies at the upcoming "44th Tokyo Motor Show 2015."

|

| |

| ["GYROBLADE" Airless Tire Technology] |

| Our "GYROBLADE" technology takes the form of a tire tread affixed to the circumference of a tire body that is composed of a metallic wheel surrounded by special resin spokes, producing a tire that fulfills all of the basic functions*2 of a tire without requiring inflation. This advancement not only removes safety concerns arising from underinflated tires due to punctures or inattention while greatly reducing maintenance work, but also contributes to the environment by eliminating the need for spare tires. Not only that, but with the special resin spokes available in a wide variety of different colors, this new technology also enables tires to make a fashion statement. |

| | *2 | Supporting the Weight of a Vehicle, Transferring Driving and Braking Power to the Road, Absorbing and Dampening Shock Maintaining and Changing Vehicle Direction |

|

|

|

|

|

|

| ["CORESEAL" Tire Sealant Technology] |

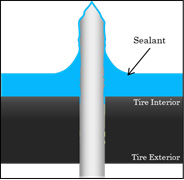

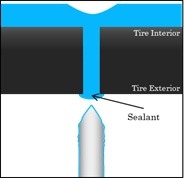

| Our "CORESEAL" technology involves applying a layer of sealant (a special material with high adhesiveness and viscosity) to the lining of a tire tread. When a tire tread is punctured*3 through to the lining, the sealant fills and blocks the hole, preventing air from leaking. This technology not only enhances safety by maintaining internal air pressure when a tire has been punctured, but also eliminates the need for spare tires, thereby saving resources, lightening vehicle loads and allowing for greater freedom in vehicle design. |

| | *3 | Prevents air leakage when a tire tread has been punctured by a nail or other foreign object of up to 5mm in diameter, regardless of whether the object remains lodged in the tread or has fallen out. |

|

|

|

|

|

|

| <CORESEAL Technology Image> |

|

|

| When Punctured by Foreign Object | | When Foreign Object Falls Out |

| | |

| |  |

| | |

| The sealant adheres to the foreign object to prevent air leakage. | | When the foreign object falls out, the sealant fills the puncture hole to prevent air leakage. |

|

|

|

|

| |

|

|