Sumitomo Rubber Industries, Ltd. is pleased to announce the unveiling of our SMART TYRE CONCEPT at the 45th Tokyo Motor Show 2017. This new technology development concept aims to aid in the development of tyres that provide balanced Safety and Environmental performance at higher levels than ever before so that we may fulfill the requirements of the mobility society of the future.

The business climate facing the automotive industry is currently undergoing massive changes-what with growing concern over environmental issues, shifting demographics brought about by increasingly urbanized and aging societies and revolutionary new technologies such as AI and IoT. At the same time, we are also witnessing the nascent emergence of a new mobility society as seen in the increasing prevalence of vehicles that are more convenient and friendlier to the environment. In response to these same changes, the tyre industry is also undergoing a major transition. And so, in order to realize "Even Greater Safety" and "Even Higher Environmental Performance," Sumitomo Rubber Industries has launched our SMART TYRE CONCEPT, a technology development concept for the development of new tyres for the dawn of a new era.

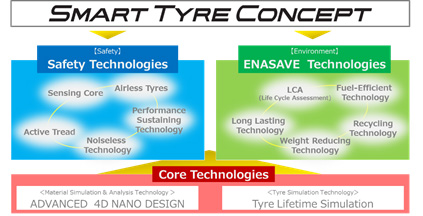

Our SMART TYRE CONCEPT is composed of three major technology categories: "Safety Technologies" to support greater safety, "ENASAVE Technologies" to make positive contributions to the environment and "Core Technologies" to support all of these efforts through the utilization of cutting-edge simulation and analysis technologies. In our DUNLOP Booth at the 45th Tokyo Motor Show 2017, Sumitomo Rubber Industries is introducing five of the research and development trends at the heart of our SMART TYRE CONCEPT: "Sensing Core," "Active Tread," "Performance Sustaining Technology," "Airless Tyres" and "LCA (Life Cycle Assessment)."

In 2020, our company plans to begin mass production of a new tyre that incorporates Performance Sustaining Technology to maintain the performance of a tyre like brand new for longer. That same year, we also plan to unveil a concept tyre that incorporates LCA, adopting new materials designed to enhance environmental performance throughout the entire lifecycle of a tyre-from raw materials and tyre production to shipping, usage and even recycling. Next, in 2023, we plan to unveil a new concept tyre that incorporates our Active Tread Technology, which will enable it to demonstrate the same high level of performance regardless of whether driving on dry roads or under any other type of road condition. Sumitomo Rubber Industries will continue these and other research and development efforts towards accomplishing our goal of creating an all-new tyre that incorporates all of our SMART TYRE CONCEPT technologies by the latter half of the next decade.

| |

| |

| [The 3 Key Technologies That Make up SMART TYRE CONCEPT] |

| |

|  |

| |

| [5 Development Trends at the Heart of SMART TYRE CONCEPT] |

| |

|  |

| |

| Safety Technology (1) : Sensing Core |

| First unveiled in May of this year, Sensing Core is an innovative new sensing technology that transforms tyres into sensors-simply by installing our proprietary algorithm in the ECU (Engine Control Unit) in a vehicle's brakes. Sensing Core is able to detect slipperiness and other road conditions as well as tyre conditions such as wear, load and air pressure. This data is collected and processed not only for vehicle control purposes, but also for cloud-based big data analysis of information pulled from sources in the same geographic area or even society at large. Further, all of this data is then provided as feedback to the vehicle so that potential hazards arising from road or tyre conditions can be detected in advance and avoided entirely. |

| |

|  |

| |

|

|

| |

| Safety Technology (2) : Active Tread |

| With the shift toward autonomous vehicles, the role of human beings in ensuring safe transportation will shrink as vehicles themselves take on a wider range of responsibilities. As tyres are the only part of a vehicle that comes into direct contact with the road, Sumitomo Rubber Industries is working to establish a new technology that responds to changes in road conditions (i.e. wet or icy roads) by actively changing the functionality of tread rubber to optimize performance for the current road surface and temperature, thus ensuring uninterrupted safe driving and peace of mind even when faced with sudden changes in road conditions during automated driving. |

| |

|

|

| |

|

|

| |

| Safety Technology (3) : Performance Sustaining Technology |

| Our new Tyre Lifetime Simulation technology is able to predict how performance will change as a tyre undergoes wear. Sumitomo Rubber Industries is utilizing these advanced simulations in our ongoing development of Performance Sustaining Technology, which aims to suppress the degradation of tire performance that occurs due to wear and rubber deterioration in order to maintain the performance of a tyre like brand new for longer. We have already put Performance Sustaining Technology to practical use in our DUNLOP WINTER MAXX 02 studless tyres, which we released on the market last year. WINTER MAXX 02 tyres feature Liquid Farnesene Rubber, a high-performance biomass material designed to be effective in maintaining rubber suppleness, which allows these tyres to maintain high on-ice performance for longer periods of time. In the future, we will continue working on research and development to suppress the degradation of tyre performance on multiple fronts, such as the development of new materials that enable rubber to control and recover from internal structural deformation and that compensate for functionality that has been lost due to rubber deterioration. |

| |

|

|

| |

| Safety Technology (4) : Airless Tyres |

| Having unveiled our prototype GYROBLADE airless tyre at the 2015 Tokyo Motor Show, Sumitomo Rubber Industries is moving forward with research and development to bring tyres that do not require inflation to market. Airless tyres contribute to greater safety and peace of mind in transportation by freeing the driver from worries about punctures and the trouble of having to manage tyre pressure. |

| |

|  |

| |

| ENASAVE Technology: LCA (Life Cycle Assessment) |

| In 2013, Sumitomo Rubber Industries released our DUNLOP ENASAVE 100, the world's first*1 100% fossil resource-free tyres made from all-natural materials. Since then, we have been working continually to develop even higher value-added proprietary biomass materials based on raw materials derived from plants. Further, we have been actively moving forward with efforts to develop and release more environmentally friendly tyres, such as our DUNLOP ENASAVE NEXT II, which achieves a 51%*2 improvement in wear resistance performance over its predecessor while maintaining the same high levels of fuel efficiency and grip performance-thanks to the utilization of our proprietary ADVANCED 4D NANO DESIGN New Materials Development Technology in its development process. In the future, we will continue working to develop products that contribute to the realization of a more recycling-oriented society by incorporating LCA to enhance the environmental performance of our products throughout their entire lifecycle-from raw materials and production to shipping, usage and even recycling. |

| *1 Since the Use of Synthetic Rubber Became Prevalent (According to Our In-House Research)

*2 ENASAVE NEXT |

| |

|

|

| |

|  | |  | | 24th Grand Prize for the Global Environment Award: Japan Business Federation Chairman's Prize |

| | |

| | 2014 Energy Conservation Grand Prize: Agency for Natural Resources and Energy Director's Award |

| | |

| | 6th Monodzukuri Nippon Grand Award: Award of Excellence |

| | |

|

|

|

|

|

| |  | |  |

|

| 2017 Nikkei Global Environmental Technology Awards: Grand Prize |

|

|

|

|

|

|

| | |

| The world's first*1 100% fossil resource-free tyre-made without using any petroleum or other fossil resources. | | This fuel-efficient tyre achieves a significant*2 improvement in wear resistance performance while maintaining the highest rating under Japan's labeling system (rolling resistance and wet grip). |

| *1 Since the Use of Synthetic Rubber Became Prevalent (According to Our In-House Research) | | *2 i.e. 51% Improvement Over Predecessor (ENASAVE NEXT) |

|

|

|