Sumitomo Rubber Industries & Ibaraki University Establish a Technique to Selectively Observe Individual Materials within Tire Rubber

Jan. 23. 2020

Sumitomo Rubber Industries, Ltd. is pleased to announce that, through joint research undertaken with Ibaraki University, we have established a new technique for selectively observing any of the various materials contained within tire rubber. Utilizing a new particle beam microscope recently developed by Ibaraki University, this groundbreaking technique makes it possible to evaluate the actual rubber that is used in mass-produced tires (rather than processed test samples), creating enormous potential for future applications in materials development. Using this technique, we have already succeeded in observing both coarse areas and fine areas (i.e. density) of sulfur cross-links*1 within rubber in vivid detail for the first time*2 ever.

*1 :Mixed into uncured rubber, sulfur serves to link polymer molecules together under the heat and pressure of the curing process, which gives the cured rubber greater elasticity.

*2 :Refers specifically to the selective observation of sulfur cross-link density at the nanometer scale (based on in-house research).

The rubber used in automobile tires is made up of dozens of different types of materials, including polymers such as natural and synthetic rubber, reinforcing agents such as carbon and silica and so forth. These various materials form complex, hierarchical structures within the rubber. And so, in order to improve overall tire performance, it is thus necessary to gain a clearer understanding of these hierarchical structures by observing the structures of each of the materials that make up tire rubber in isolation. In particular, the structures formed by sulfur cross-links, which give rubber its elasticity, have long been thought to be closely related to rubber strength and changes in rubber properties over time (such as degradation) as well. However, up until now, the details of these structures within rubber have remained shrouded in mystery.

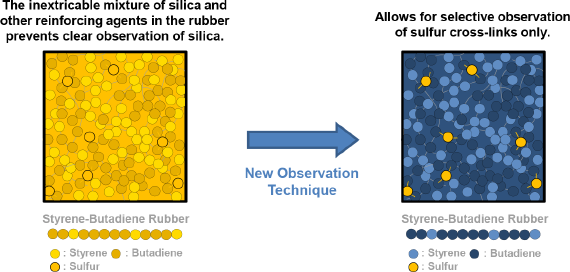

Responding to this challenge, Sumitomo Rubber Industries teamed up with Ibaraki University to establish a new technique for selectively observing specific materials within tire rubber. As a result of this joint research, we have already demonstrated that it is possible to selectively observe the density of sulfur cross-links in rubber. While conventional observation techniques only provide image data that shows an inextricable mixture of sulfur and other reinforcing agents, this new technique generates clear images in which specific compound components, such as sulfur cross-links or other reinforcing agents, are each assigned specific colors. By allowing us to evaluate the very structures of tires themselves, this image data can be used to come up with internal structures for tires that will provide superior performance in terms of fuel efficiency, wear resistance and so forth. Thus, this new breakthrough creates enormous potential for the acceleration of the material development process.

■Image: Observation of Sulfur Cross-Link Density within Styrene-Butadiene Rubber (SBR)