Shedding Light on the Chemical Bonds Between Sulfur & Natural Rubber~Joint Research with Tokyo Institute of Technology & RIKEN~

Oct. 26. 2022

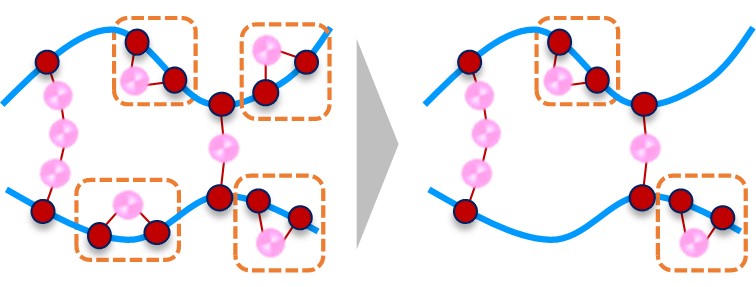

Sumitomo Rubber Industries, Ltd. is pleased to announce that, as a result of joint research undertaken with Professor Yoshitaka Ishii of Tokyo Institute of Technology and Visiting Researcher Muneki Ouchi of RIKEN, we have shed new light on the mysteries surrounding the vulcanization process of rubber in tire manufacturing, which involves chemical reactions between raw rubber and sulfur under intense heat and pressure. Focusing on the chemical bonds that form between natural rubber and sulfur as a result of these reactions, our research team has succeeded for the first time in detecting the presence of ring structures, which potentially have an impact on the basic performance of tires. Moving forward, we will be working to develop new techniques that will allow us to adeptly control the bridge structures and ring structures that fill in and connect the gaps between natural rubber molecules so that we may then utilize this technology to further improve overall tire performance.

|

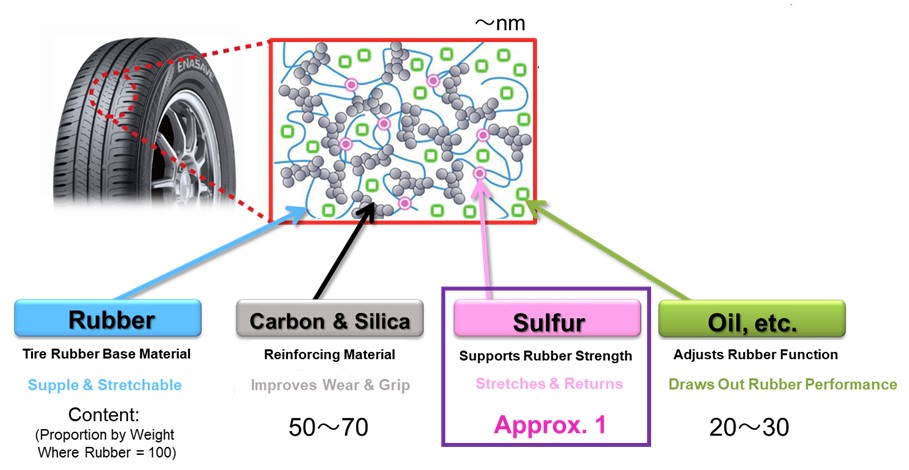

| Raw Materials of Tire Rubber |

|

|

|

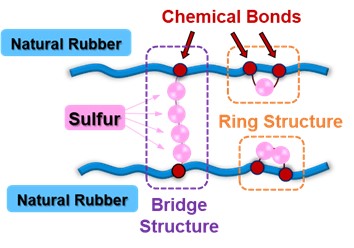

Natural Rubber & Sulfur Chemical Bond Image |

Image Showing Envisioned Control of Ring Structure Formation |

In 1888, John Boyd Dunlop created the world’s first practical pneumatic tire. However, this feat would not have been possible without the discovery of vulcanization in 1839, which set the stage for the development of rubber tires.

Formed during the vulcanization process, sulfur bridge structures give rubber its elasticity while playing a major role in basic tire performance as well as performance retention. However, as sulfur only accounts for around 1% of the raw materials that constitute tire rubber, prior research has made little progress when it comes to shedding light on the structures of the chemical bonds between rubber and sulfur. And so, our team set out to advance research in this area with a particular focus on sulfur, a critical raw material that has an outsized impact on tire performance in spite of making up only 1% of tire rubber.

Through this recent research, we have not only shed new light on the structures of the chemical bonds that form between natural rubber and sulfur but have also succeeded in detecting for the first time the presence of ring structures, which potentially affect the basic performance of tires. The Sumitomo Rubber Group intends to apply the results of this research to accelerate the Development of “Performance Sustaining Technology,” one of the core technologies of our SMART TYRE CONCEPT*1 for the development of tires and peripheral services of the future.

The Sumitomo Rubber Group is fully committed to working on creating solutions to various issues with respect to the natural environment, social harmony and corporate governance as part of our overall efforts to accomplish the goals of our Long-Term Sustainability Policy: “Driving Our Future Challenge 2050.”

Our Tire Business has been working to develop advanced biomass raw materials since long before the term “carbon neutral” came into common usage. Thanks to these pioneering efforts, in 2013, we released ENASAVE 100, the world’s first*2 100% fossil resource-free tires made from all-natural raw materials. By continuing to advance and expand upon the technologies that made ENASAVE 100 possible, we are now working to increase the Sustainable Raw Material Content*3 of all tires that we produce to 40% by the year 2030, with the ultimate aim of realizing 100% Sustainable Tires by the year 2050. Over 180 years after the discovery of vulcanization, we are now returning to square one with research on the material that makes this process possible: sulfur. Through this ongoing research, the Sumitomo Rubber Group will continue working to contribute to the realization of sustainable societies through further improvements in tire performance.

In addition, we are also pleased to announce that the results of this research were published in the October 25, 2022 issue of “Biomacromolecules,” which is an academic journal published by the American Chemical Society.

<Official Website of Biomacromolecules >

https://pubs.acs.org/doi/10.1021/acs.biomac.2c00141

※2. Since the Use of Synthetic Rubber Became the Norm (Based on In-House Research)

※3. The Total Content of Both Biomass Raw Materials & Recycled Raw Materials as a Percentage by Weight

<Reference>

■RIKEN Press Release