Sumitomo Rubber and Kyoto University Succeed in Three-Dimensional Visualization of Internal Rubber Structure : To Be Utilized for Development of Tires with Enhanced Antiwear Performance 3D Visualization of Different Material Distributions in Internal Rubber Structure that Lead to Fracture

Jul. 23. 2025

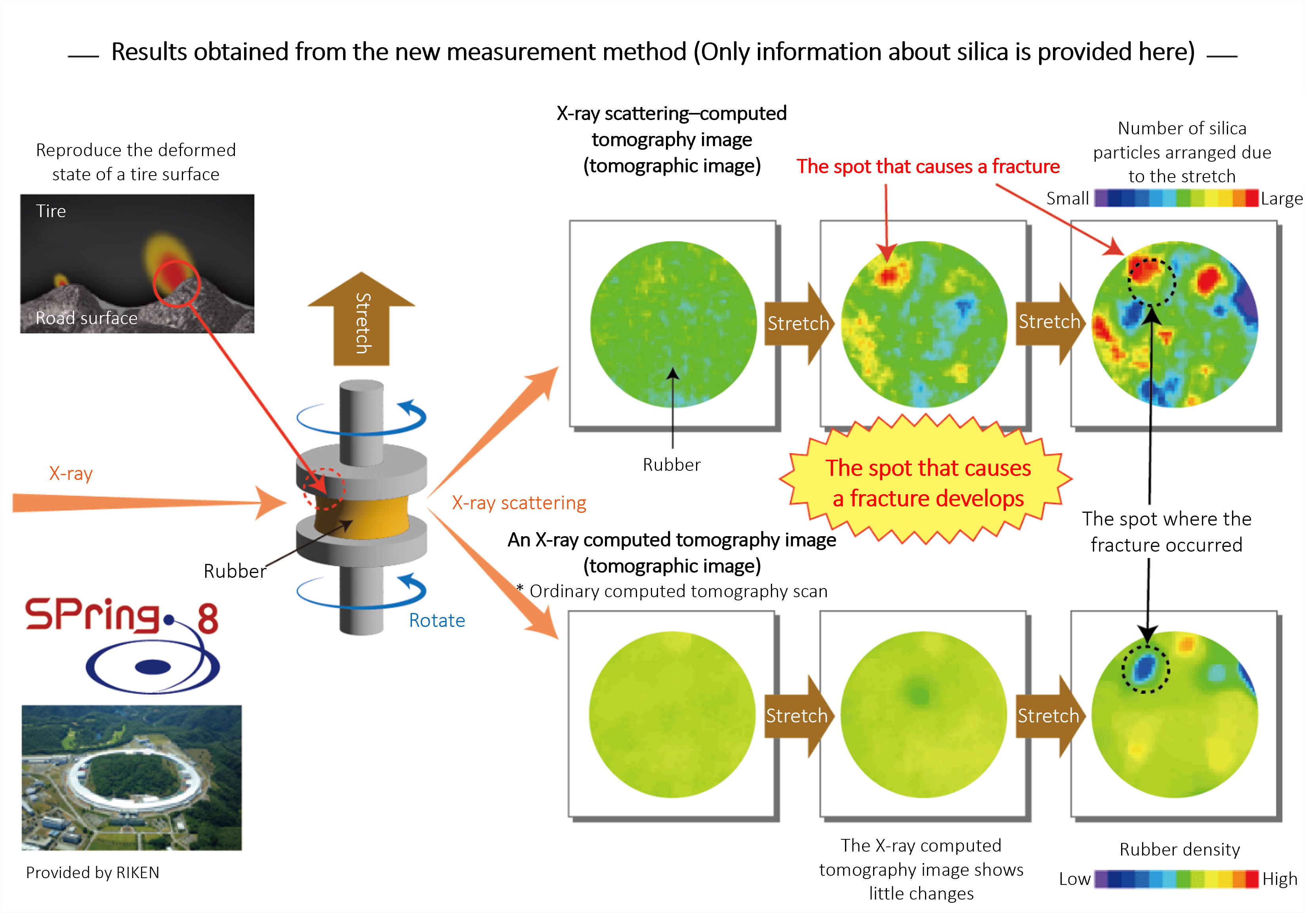

Sumitomo Rubber Industries, Ltd. is pleased to announce that it has, in cooperation with Associate Professor Hiroki Ogawa at the Institute for Chemical Research, Kyoto University, succeeded in three-dimensional visualization of different material distributions in the internal structure of rubber that lead to fracture. This enables in-depth observation of changes in the internal structure of rubber when it is fractured. In the past, it was impossible to identify where fracture begins when the rubber is deformed and how the internal structure, which causes the fraction, is related.

The outcome of this research has been produced through an industry-university cooperation project between Sumitomo Rubber, which has a wide knowledge of rubber, and the Institute for Chemical Research, Kyoto University, which has the technology for three-dimensional visualization of different material distributions in the internal structure of rubber.

We will use this research outcome to advance the development of tires with enhanced antiwear performance, and thereby contribute to improving safety and reducing environmental burden.

|

|

|

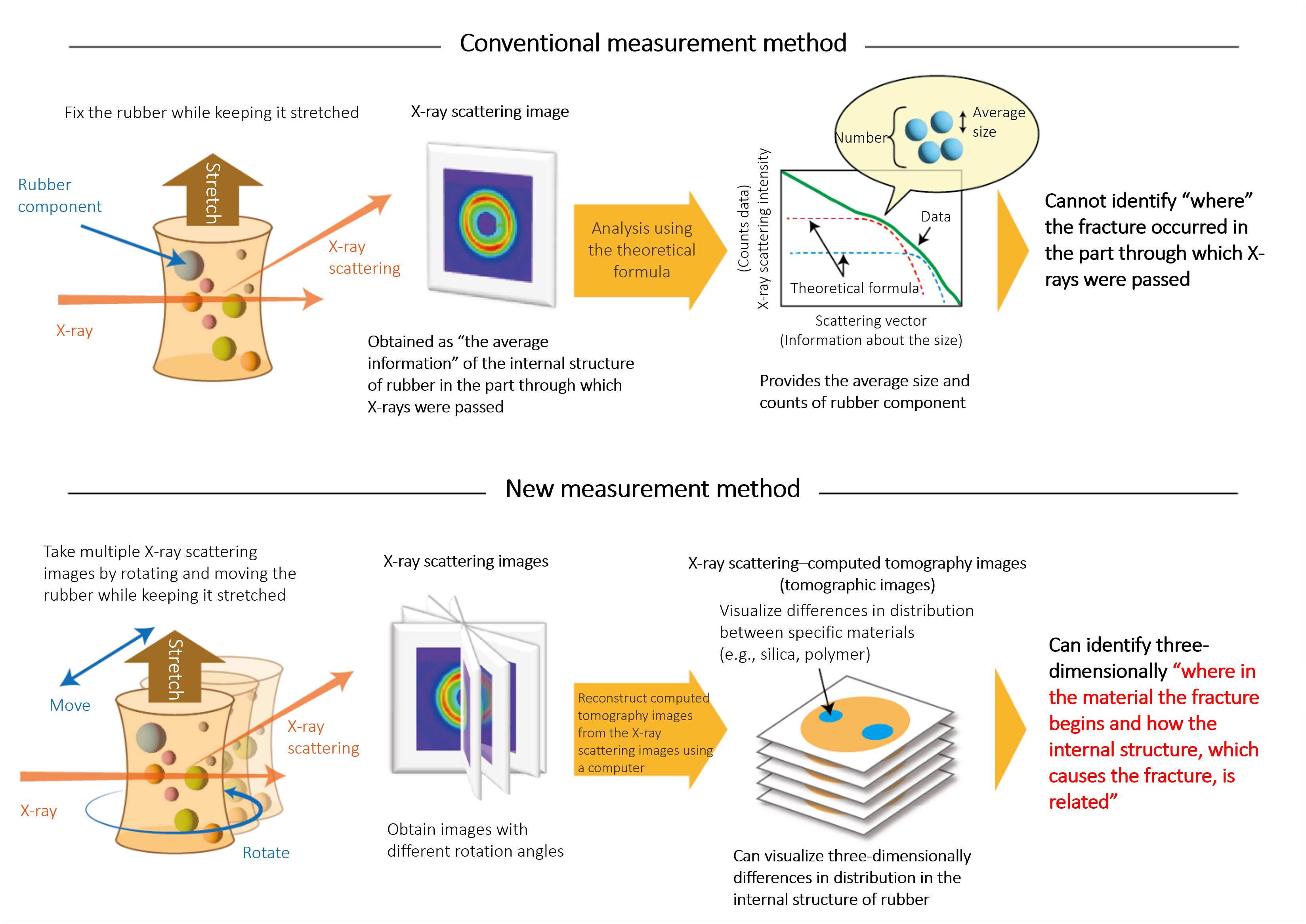

Figure 1: Differences between conventional and new measurement methods |

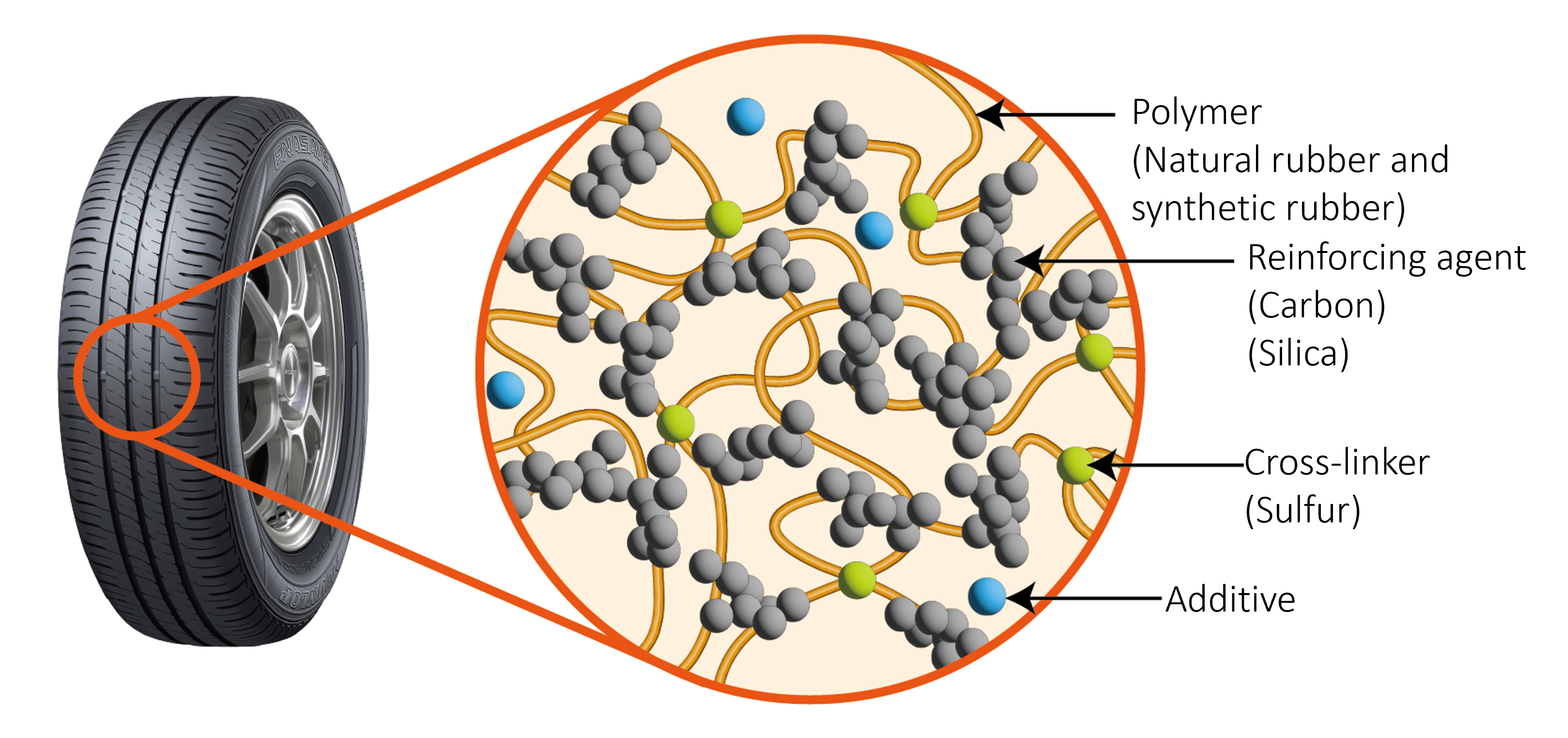

| Sumitomo Rubber has developed tire rubber materials with low fuel consumption and superior antiwear performance by analyzing the internal structure of rubber in detail using SPring-8,*1 a large synchrotron radiation facility.*2 The internal structure of tire rubber is composed of more than 10 types of materials, including polymer, which serves as the skeleton; silica and carbon black, which are reinforcing agents; and additives and cross-linkers used to enhance performance. The conventional method*3 was only able to provide the average information of the internal structure of rubber in the part through which X-rays were passed, and accordingly, they were unable to identify where the fracture occurred in the part through which X- rays were passed when rubber was deformed to cause the fracture (Figure 1). |

|

|

|

Figure 2: Visualizing different material distributions in the internal structure that lead to rubber fracture |

Going forward, we will use this research outcome for the development of rubber materials and advance the development of tires with superior antiwear performance that contributes to improving safety and reducing environmental burden.

Against the backdrop of an increase in vehicle weight due to the spread of electric vehicles (EVs) and of increasing interest in reducing environmental burden, such as saving resources, there is a growing need for tires that last longer. In the Long-term Corporate Strategy R.I.S.E. 2035, our vision is defined as “Continuing to Provide “New Experiential Value” Born from Rubber to Everyone” by taking advantage of our strengths: “Rubber and Analytical Technology” and “Brand Creation Capability.” This research outcome demonstrates the strengthening of “Rubber and Analytical Technology” through industry-university cooperation and the use of the most advanced research facility.

This research is part of the NEDO Feasibility Study Program,*5 a project promoted by the New Energy and Industrial Technology Development Organization (NEDO). The research outcome was published in the international journal Small Structures.*6 on July 22.

<Reference>

- Long-Term Corporate Strategy R.I.S.E. 2035.

- An article published in Small Structures, H. Ogawa, et al. Small Struct. 2500257 (2025).

*1: A large synchrotron radiation facility which delivers the most powerful synchrotron radiation currently available (located in Sayo-cho, Sayo-gun, Hyogo Prefecture)

*2: Establishment of Four-Dimensional (4D) Nano Design, a Technology for the Development of New Materials Used for High-Performance and High-Quality Tires—Acceleration of development of tires with reduced environmental impact and high safety (Press release) http://www.spring8.or.jp/ja/news_publications/press_release/2011/111212/

*3: Small-angle X-ray scattering (SAXS) technique: A technique to study the structure of materials by applying X- rays to the object and observing how the X-rays bounce off (scatter)

*4: Small-angle x-ray scattering computed tomography (SAXS-CT): A technique to visualize the arrangement of materials in the object by applying X-rays from the surroundings of the object, as in the case of CT scans, and observing the X-rays scattered by the materials contained in the object. Computed tomography images that visualize the density of an object (ordinary X-ray computed tomography scans) can also be obtained simultaneously by measuring the X-ray transmission factor.

*5: A program promoted by the New Energy and Industrial Technology Development Organization (NEDO). The program aims to discover and nurture fundamental technologies expected to be practical and socially implemented after 2040 (more than 15 years from the start of feasibility study). The goal is to promote these technology developments to collaborative research within the academia-industry framework, including national projects, contributing to the realization of decarbonized society and the creation of new industries. The research presented in this news release is a project under the Feasibility Study Program on Creation of New Industries and Innovative Technologies.

*6: Small Structures is a high-quality, specialist journal that publishes cutting-edge research findings on sub-macroscopic structures (minute structures smaller than macroscale) across various dimensions and multiple disciplines, including chemistry, physical & materials science, engineering, and life sciences.