Sumitomo Rubber and Mitsubishi Chemical Launch Collaboration to Recycle Carbon Black for Tires

Jan. 30. 2025

Sumitomo Rubber Industries, Ltd. and Mitsubishi Chemical Corporation (Chiyoda, Tokyo; Representative Directors: Yasuo SHIMODAIRA and Nobuo FUKUDA; “Mitsubishi Chemical”) will launch a joint project for the recycling of carbon black, one of the main raw materials of tires, in January 2025.

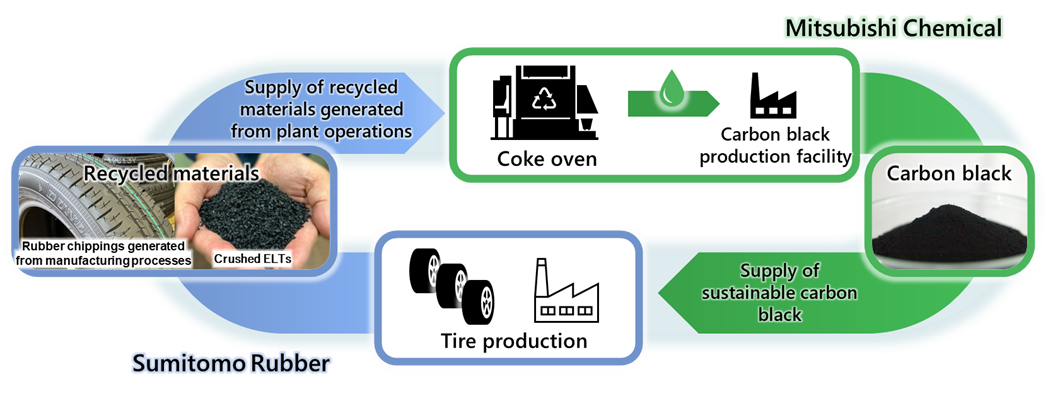

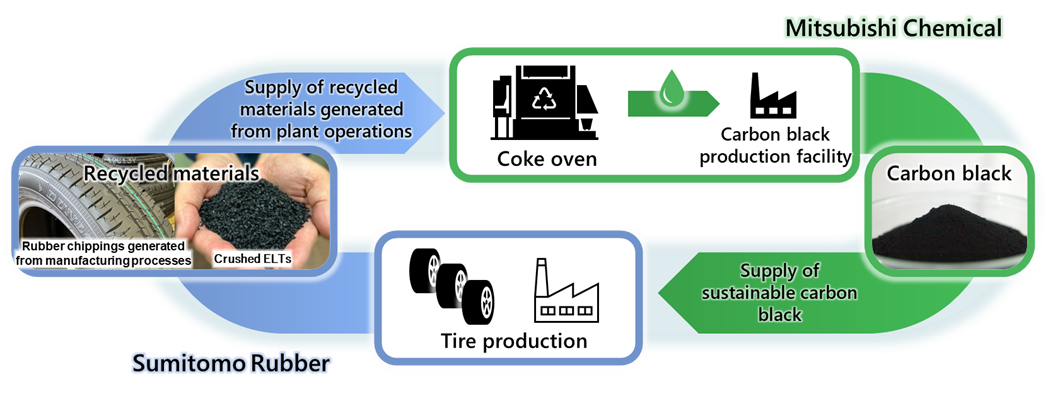

According to the collaboration plan, Sumitomo Rubber will supply rubber chippings (recycled materials) generated from tire manufacturing processes and crushed end-of-life tires (“ELTs”) to Mitsubishi Chemical. At Mitsubishi Chemical, these materials will be fed into coke ovens as raw materials for chemical recycling*1 to produce carbon black again from the tar. The resulting sustainable carbon black will be used as raw material for tires to be produced by Sumitomo Rubber.

Sumitomo Rubber manufactures and sells various types of tires globally, principally under the brand names of DUNLOP and FALKEN. Under its own unique Circular Economy Concept for the Tire Industry, TOWANOWA, Sumitomo Rubber is committed to utilizing ELTs as recycled tire materials. In the planned collaboration, Sumitomo Rubber will adopt the sustainable carbon black for two different types of tires—some race cars and passenger cars—to be produced from 2025. The scope of adoption is planned to be expanded from 2026 onward.

Mitsubishi Chemical produces carbon black, one of the main raw materials and a rubber reinforcing agent used in tires. Conventionally, carbon black is manufactured using heavy oil (such as tar) derived from coal and oil as the raw material. As an alternative route, the company has been examining the possibility of a chemical recycling process that uses end-of-life tire materials as the raw material. In July 2024, Mitsubishi Chemical started demonstration experiments of the developed process to assess its impact on existing processes, and based on the results, it has decided to commercialize the sustainable carbon black. This marks the world’s first-ever commercialization*2 of such products made from recycled tires using coke ovens.

Sumitomo Rubber and Mitsubishi Chemical will work together to contribute to realizing a circular economy in the automobile and tire industries.

Reference:

Sumitomo Rubber: press release (March 8, 2023) Introducing a Circular Economy Concept for the Tire Industry: TOWANOWA

https://www.srigroup.co.jp/english/newsrelease/2023/sri/2023_018.html

Mitsubishi Chemical Group: press release (August 22, 2024)Launch Studies on Chemical Recycling of End-of-Life Tires Utilizing Coke Ovens

https://www.mcgc.com/english/news_release/02044.html

*1. Recycled materials are to be mixed with coal and fed into coke ovens. Chemical recycling refers to a recycling method in which end-of-life resources are chemically decomposed to be turned into raw materials for new production.

*2. Survey by the Mitsubishi Chemical Group

According to the collaboration plan, Sumitomo Rubber will supply rubber chippings (recycled materials) generated from tire manufacturing processes and crushed end-of-life tires (“ELTs”) to Mitsubishi Chemical. At Mitsubishi Chemical, these materials will be fed into coke ovens as raw materials for chemical recycling*1 to produce carbon black again from the tar. The resulting sustainable carbon black will be used as raw material for tires to be produced by Sumitomo Rubber.

Sumitomo Rubber manufactures and sells various types of tires globally, principally under the brand names of DUNLOP and FALKEN. Under its own unique Circular Economy Concept for the Tire Industry, TOWANOWA, Sumitomo Rubber is committed to utilizing ELTs as recycled tire materials. In the planned collaboration, Sumitomo Rubber will adopt the sustainable carbon black for two different types of tires—some race cars and passenger cars—to be produced from 2025. The scope of adoption is planned to be expanded from 2026 onward.

Mitsubishi Chemical produces carbon black, one of the main raw materials and a rubber reinforcing agent used in tires. Conventionally, carbon black is manufactured using heavy oil (such as tar) derived from coal and oil as the raw material. As an alternative route, the company has been examining the possibility of a chemical recycling process that uses end-of-life tire materials as the raw material. In July 2024, Mitsubishi Chemical started demonstration experiments of the developed process to assess its impact on existing processes, and based on the results, it has decided to commercialize the sustainable carbon black. This marks the world’s first-ever commercialization*2 of such products made from recycled tires using coke ovens.

Sumitomo Rubber and Mitsubishi Chemical will work together to contribute to realizing a circular economy in the automobile and tire industries.

Reference:

Sumitomo Rubber: press release (March 8, 2023) Introducing a Circular Economy Concept for the Tire Industry: TOWANOWA

https://www.srigroup.co.jp/english/newsrelease/2023/sri/2023_018.html

Mitsubishi Chemical Group: press release (August 22, 2024)Launch Studies on Chemical Recycling of End-of-Life Tires Utilizing Coke Ovens

https://www.mcgc.com/english/news_release/02044.html

*1. Recycled materials are to be mixed with coal and fed into coke ovens. Chemical recycling refers to a recycling method in which end-of-life resources are chemically decomposed to be turned into raw materials for new production.

*2. Survey by the Mitsubishi Chemical Group