The Sumitomo Rubber Group places strong emphasis on conducting sustainable business activities while coexisting in harmony with society and the environment. To serve as a major driving and accelerating force for achieving the company’s overall strategy, the group established a new corporate philosophy system, “Our Philosophy,” in December 2020. The group defines its Purpose—its reason for being—as “Through innovation we will create a future of joy and well-being for all.”

By making this Purpose the foundation for all decision-making and the starting point for all actions, the group strives to enhance not only economic value but also social value, contributing to the development of a sustainable society.

To realize “Our Philosophy,” the group identifies Material Issues by considering risks and opportunities throughout the value chain. Among these identified Material Issues, “Climate Change,” “Biodiversity,” and the “Circular Economy” are deeply interconnected. The group believes in addressing these issues through an integrated approach rather than in isolation and actively engages in related initiatives.

Our group aims to establish a circular economy business model across the entire supply chain, centered on our core tire business. We also incorporate the concept of Life Cycle Assessment (LCA) to evaluate and reduce environmental impact throughout the entire product lifecycle, striving to minimize resource use and reduce the environmental impact of our products.

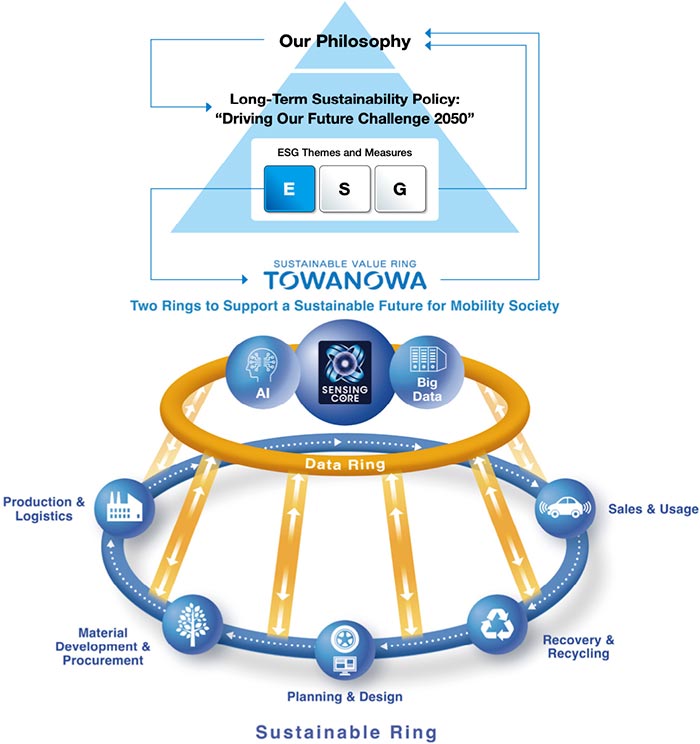

Vision of and Value Delivered by TOWANOWA

Encapsulating our hope to support the long-lasting development of a sustainable mobility society in the future, the word TOWANOWA brings together the two Japanese terms TOWA, meaning “Everlasting,” and WA, meaning “Ring.”

In line with the TOWANOWA concept, we aim to facilitate the circulation and effective utilization of limited resources while promoting the use of big data, comprising data gleaned by such technologies as SENSING CORE, an asset unique to the Company. Through these efforts, we will deliver new value to customers, contribute to the creation of the next-generation mobility society and otherwise help realize a sustainable future in which all people can enjoy safety, security and comfort. We will thus promote the “TOWANOWA” concept to materialize a long-lasting tire business cycle as part of efforts to embody “Our Philosophy.” In the course of doing so, we will help realize a sustainable world and contribute to the creation of a future of joy and well-being for all.

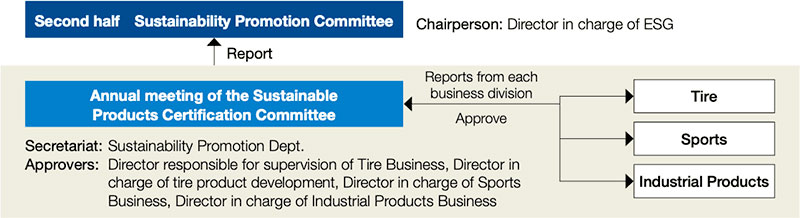

The Sumitomo Rubber Group is promoting initiatives for a circular economy in an integrated manner, led by the Sustainability Management Promotion HQ and in collaboration with top management and other departments. To promote sustainability management, the Sustainability Promotion Committee, which is chaired by the Executive Director in Charge of Sustainability and consists of officers in charge of respective divisions as its members, meets twice a year to enforce Group-wide policies and monitor the progress on material issues.

Under the Sustainability Promotion Committee, subcommittees are established as working groups, with the Circular Economy (TOWANOWA) Subcommittee being one of them. This subcommittee operates as a cross-departmental organization to promote initiatives. Our group has outlined efforts towards achieving resource circulation by fiscal year 2050 in its Long-Term Sustainability Targets: “Driving Our Future Initiatives” to realize a circular economy.

The expanding impacts of climate change have prompted a shift toward carbon neutrality, alongside significant changes in labor and human rights issues, reshaping the corporate landscape. Furthermore, advancements in mobility are driving changes in industrial structures and creating new competitive environments.

“TOWANOWA” is composed of two interconnected rings: the orange “Data Ring,” which leverages data collected from each stage of the value chain to create new value, and the blue “Sustainable Ring,” which integrates and circulates the flow of materials across processes, eliminating waste and aiming for the realization of a circular economy. By merging these two rings, TOWANOWA generates innovative value and fosters sustainable business practices.

|

Data Ring

|

|

|

Sustainable Ring

|

|

| Risks | Opportunities | |

|---|---|---|

|

Physical Risks

|

Acute and Chronic

|

Climate change |

|

Transition Risks

|

Policies, laws and regulations

|

Environmental regulations and changing customer needs |

|

Transition Risks

|

Technology

|

Changes in business models due to technological advances |

|

Transition Risks

|

Market

|

Supply chain fluctuations |

|

Transition Risks

|

Market

|

Increased response costs due to stricter environmental regulations |

|

Transition Risks

|

Technology

|

Separation and reuse of composite materials |

|

Transition Risks

|

Technology and Market

|

Rising costs of retreaded tires and recycled raw materials |

|

Transition Risks

|

Market

|

Illegal dumping and lack of disposal infrastructure |

|

Transition Risks

|

Market

|

Risk of price fluctuations in natural rubber and petroleum-derived raw materials |

|

Transition Risks

|

Policies and laws

|

Issues or challenges related to CO2 emissions and waste disposal |

| Opportunity Classification | Opportunity |

|---|---|

|

Markets, Products and Services

|

|

|

Markets, Products and Services

|

|

|

Markets, Products and Services

|

|

|

Energy Source

|

|

|

Market

|

|

|

Products and Services

|

|

|

Market

|

|

|

Market and Resource Efficiency

|

|

|

Resource Efficiency

|

|

|

Energy Source

|

|

|

Resilience

|

|

The Circular Economy Subcommittee (TOWANOWA Subcommittee), established under the Sustainability Promotion Committee, took the lead in gathering internal and external information. Based on the company's business characteristics, it assessed risks related to resource circulation and sustainable raw materials. The subcommittee's activities are determined based on the results of this risk assessment.

| Item | Details |

|---|---|

|

Risk management process

|

|

|

Specific management methods

|

|

We have set target values as a KPI for each process that makes up the sustainable ring.

| Process | Value provision | Item | Target year |

|---|---|---|---|

|

Planning & Design  |

Higher performance × Efficient resource usage

|

|

|

|

Material Development & Procurement  |

Promoting resource circulation and reducing CO2 emissions

|

|

|

|

Sales &Usage  |

Proposing optimal tires for customers

|

|

|

|

Recovery & Recycling  |

Promoting retread tires

Putting End-of-Life Tire (ELT) to use

|

|

|

For more information, please visit the following page.

The targets and results are as follows.

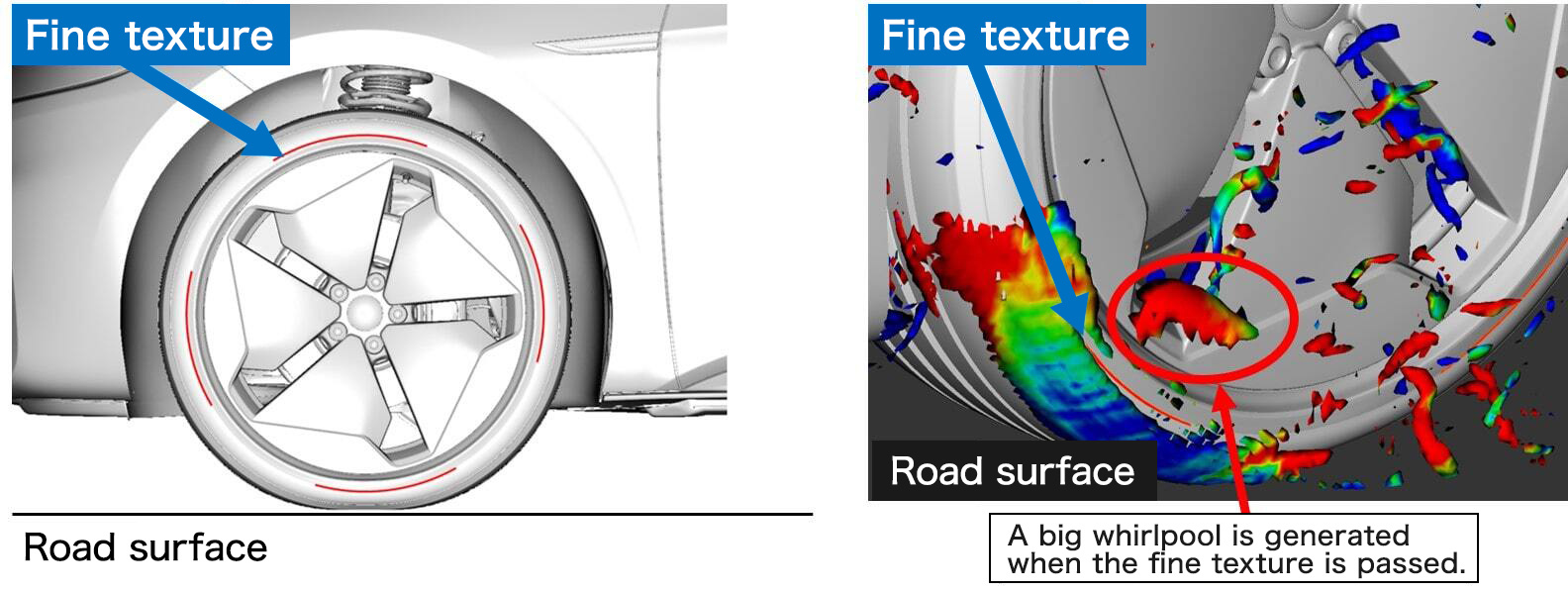

Sumitomo Rubber Industries aims to develop a tire that further contributes to lowering the electricity consumption of an EV as a next-generation EV tire to be launched in 2027.

The “Tire Aerodynamic Simulation” is a simulation technique that visualizes airflow around a tire and its impact (aerodynamics). A unique characteristic of this technique is its ability to calculate the aerodynamics of a rotating tire, using actual vehicle data, by simulating the tire pattern and changes in the tire shape in contact with the road surface caused by vehicle weight, through the use of AI technologies. In addition, we have newly developed a simulation technique that changes the shapes of the lettering and fine texture on the sidewall while they are rotating. While it is important to smoothen the sidewall to reduce air resistance in EV tires, the use of the newly developed simulation technique will enable the development of a tire that achieves both design and air resistance reduction at higher levels.

“Tire Aerodynamic Simulation” that takes into account sidewall lettering and fine texture

Our Group aims to increase the content of sustainable raw materials in its tires to 40% by 2030 and 100% by 2050 to ultimately reduce the volume of CO<sub>2</sub> emissions throughout the supply chain. In the motorsports field, which is at the front line of tire development, we will accelerate our initiatives to realize carbon neutrality by developing products using sustainable raw materials.Our company announced a new wet tyre for EV karts at the 2025 All Japan Kart Championship EV Division. This tyre successfully increased the sustainable raw material ratio from approximately 15% to 49%. Additionally, at the fourth round of the 2025 SUPER GT, we introduced tires featuring recycled carbon black for the GT300 class. These tyres delivered consistently stable performance throughout, enabling the equipped vehicle to win both Race 1 and Race 2 consecutively over the two-day event.

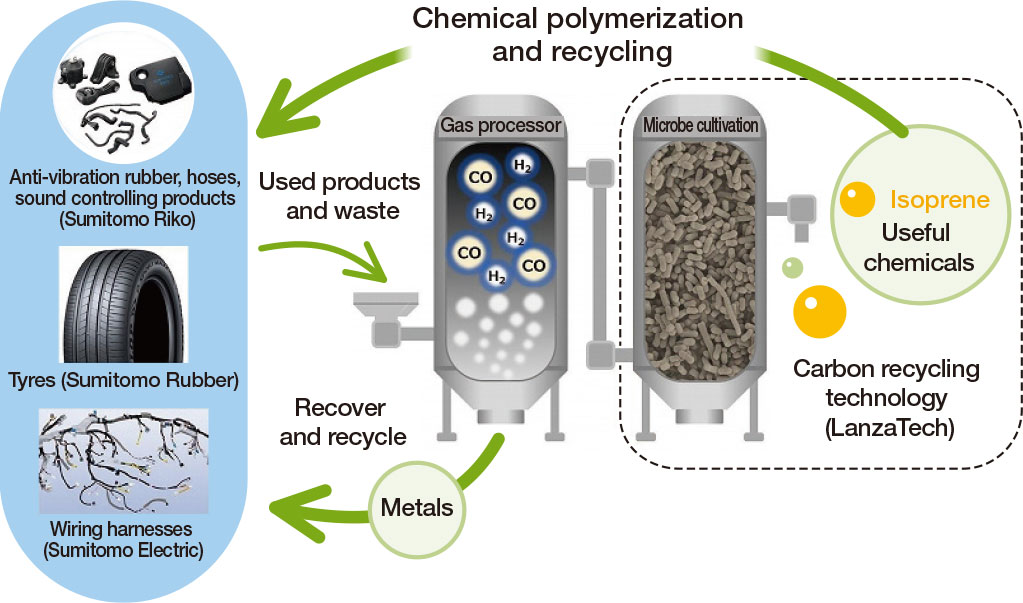

To realize innovation that enables us to create a future of joy and well-being for all, we have not only adopted sustainable raw materials but have taken on a challenge to develop sustainable raw materials on our own. Together with Sumitomo Riko and Sumitomo Electric, we are now pushing ahead with the development of new technologies in collaboration with LanzaTech. We aim to leverage LanzaTech’s carbon recycling technology to turn waste materials like tires into isoprene, which can be used as new rubber materials. This will be achieved by gasifying the waste materials and purifying the resulting gas, and then putting them through a fermentation process that transforms the gas into new raw materials. Working alongside raw materials manufacturers, we are also exploring the feasibility of establishing a recycling technology that enables the reuse of isoprene as materials for rubber and resin. We are also contemplating the idea of recycling the metals recovered during the gasifying process and reusing them as raw materials.

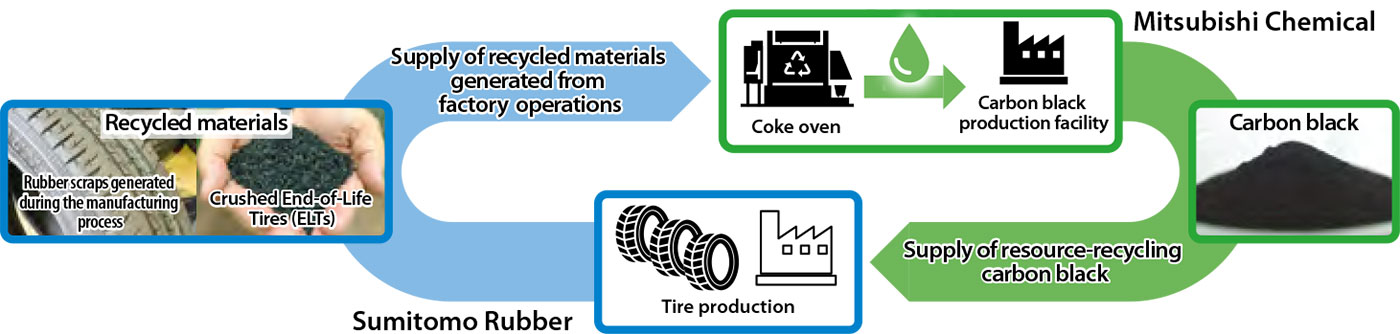

We supply rubber chippings (recycled materials) generated from tire manufacturing processes and crushed end-of-life tires (ELTs) to Mitsubishi Chemical. At Mitsubishi Chemical, these materials are fed into coke ovens as raw materials for chemical recycling to produce carbon black again from the tar. The resulting sustainable carbon black is used as raw material for tires to be produced by the Company. This marks the world’s first-ever commercialization of such products made from recycled tires using coke ovens.

We adopted the sustainable carbon black in 2025 for two types of tires—those for race cars and certain passenger cars. The scope of adoption is planned to be expanded from 2026 onward.

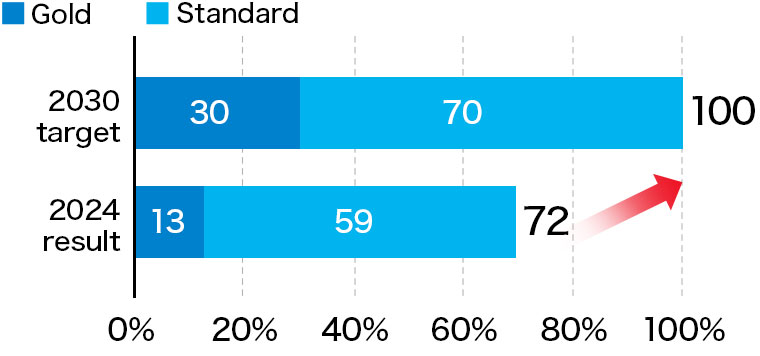

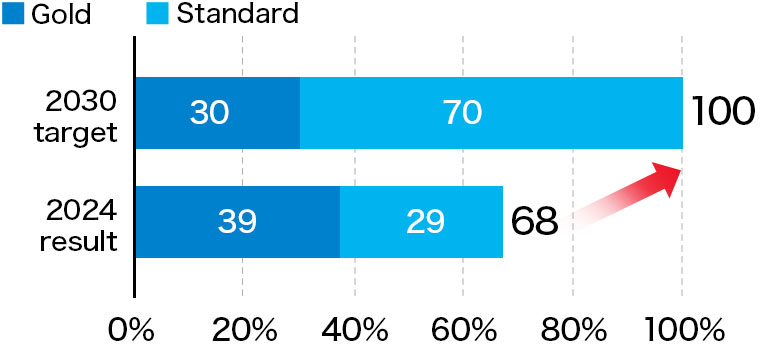

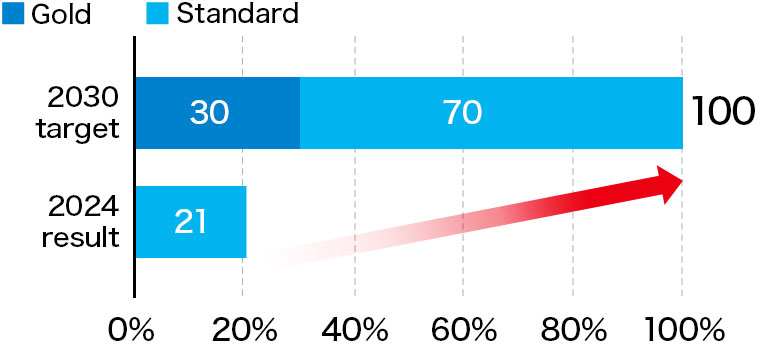

In 2023, the Sumitomo Rubber Group introduced a certification system for sustainable products based on internal standards as part of measures specified in its Long-Term Sustainability Targets: “Driving Our Future Initiatives”

We thus apply our own assessment standards to the selection and certification of sustainable products from among all offerings of our Tire, Sports, Industrial Products and other businesses. Assessment items are set for each product group and include the ratio of sustainable raw materials used, the type of energy consumed in manufacturing processes, and the product’s recyclability after use. Products that meet bare minimum requirements are designated as “Standard” certification, while products boasting outstanding features in terms of sustainability are designated as “Gold” certification. Our current aim is to ensure that all products are certified “Standard” by 2030 and, to this end, are striving to update their features.

Looking ahead, we will continue to develop an internal certification framework to identify products capable of contributing to global warming countermeasures and environmental load reductions throughout their life cycles. By doing so, we will align our product development approach with a progressive shift to a business model in favor of circular economies.

We aim to achieve “standard” or above for all products by 2030.

The following diagram shows the flow of our certification scheme. First, separate product development committees are convened to examine Tire, Sports, and Industrial Products business offerings to determine candidate products. Directors then screen these products at the annual meeting of the Sustainable Products Certification Committee to finalize those worthy of certification. Through this scheme, we will promote the development of an internal structure for incorporating sustainability elements into product development.

We have identified “Reducing Plastic Usage” as part of the measures stipulated under Long-Term Sustainability Targets: “Driving Our Future Initiatives”. In this regard, we are promoting initiatives to reduce packaging materials in all of our businesses to reduce plastic usage by 40% in 2030 compared to 2019 levels. In particular, in the Sports Business, which uses a large amount of plastic in packaging materials, we are phasing out window film in the packaging of golf balls released in the fall of 2021 and thereafter. In addition, from 2023, the plastic lids of PET packaging tubes for DUNLOP AUSTRALIAN OPEN and DUNLOP FORT tennis balls sold domestically will be replaced with paper ones. Plastic lids for the St. JAMES brand training balls and other products were eliminated, and the labels were replaced with paper ones that slip inside the containers.

For the relevant article, please visit the following page.

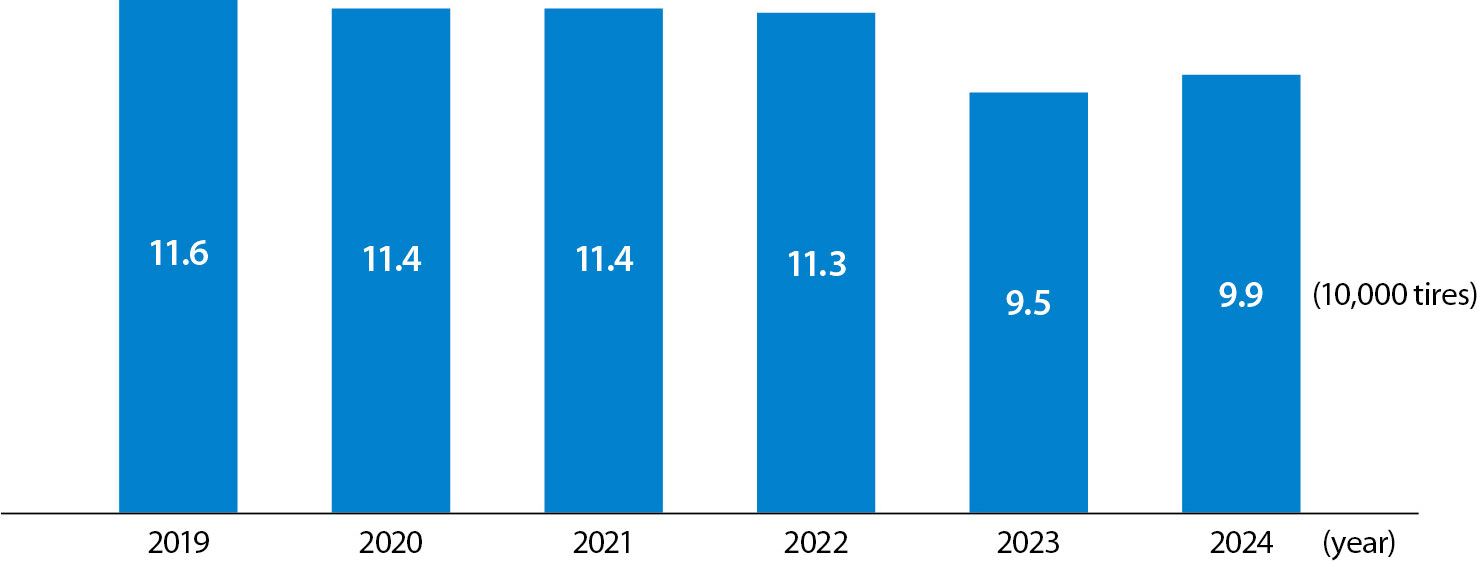

We have positioned retreading* tires as one of the important initiatives in establishing a circular business model, aiming to increase the sales volume of retread tires in Japan to 190% of the level in 2021 by 2030. In addition, we will improve the rate of recovering quality base tires for retreading and the number of retreading to reduce tires to be disposed of by leveraging the information and history of use of tires obtained through the Tire Pressure Monitoring System (TPMS) and Radio Frequency Identification (RFID) as well as SENSING CORE.

<div class="mt-20 text-small">* Retreading refers to a process for recycling worn-out tires by removing the spent tread and then applying new tread rubber to the tire casing.</div>

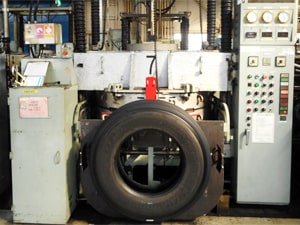

Our group manufactures retread tires utilizing the remolding method. The remolding method refers to a method that involves shaving off the rubber tread surface of a base tire, affixing non-cured rubber on the exposed surface and then curing it.

In this method, the robust cohesion of freshly affixed tread rubber with the base tire results in a retread tire with a beautiful outward appearance as well as high quality and high performance.

In addition, high-temperature, high-pressure steam generated by boilers fueled by fossil fuels was previously used as a heat source for curing. We also work to reduce CO2 emissions during retread curing by replacing steam with electricity as the heat source in some of our curing equipment.

| Initial inspection |

|

Base tires are scanned by inspection machines upon reception. Based on rigorous standards and screening, only tires that satisfy the necessary criteria can proceed to the next process. |

|---|---|---|

| ▼ | ||

| Shearography inspection |

|

A non-destructive testing method that can detect internal abnormalities not visible through a standard visual inspection. |

| ▼ | ||

| Buffing |  |

The buffing machine shaves off the surface of tread rubber and finishes the base tires into a predetermined shape and size. |

| ▼ | ||

| Shaping |  |

Properly shaped fresh retreading rubber is affixed to the buffed area. |

| ▼ | ||

| Curing |  |

Shaped ties are put into metal molds and subjected to heat and pressure for a specific time. |

| ▼ | ||

| Final inspections |

|

Finished retread tires undergo rigorous inspections of their outward appearance, internal structure, and other aspects. Only products deemed satisfactory in every respect can be shipped. |

In October 2023, the Company released replacement tires equipped with RFID which allows for individual tire identification. These tires specifically include DUNLOP “e. ENASAVE SP148,” a rib tire for EV route buses, and DUNLOP “ALL SEASON MAXX AS1 for TAXI,”*2 an all-season tire for taxis. RFID is a wireless communication technology that uses radio waves for individual identification, instead of conventional barcodes or QR code, for traceability purposes, including quality assurance, responses to customer complaints, and elimination of counterfeit tires. In January 2023, the Company joined the Global Data Service Organisation for Tires and Automotive Components (GDSO), an international association developing industry standards for the traceability of tires. The Company then satisfied a range of requirements, such as the impact of RFID on tire performance, a challenge when it is equipped with mass-produced tires, and the durability of RFID tags, and succeeded in releasing tires equipped with RFID this time. RFID built into tires will enable acquiring tire data in various stages, such as manufacturing, sales, and use, in the future. We expect that we can eventually improve the number of retreading, promote the recycling of materials, as well as enhancing safety and operational efficiency, by analyzing the status of use and driving history. Going forward, we will strive to develop solution businesses, focused on retreading and maintenance, to provide high-value-added services tailored to customers’ situations and needs.

*1 Based on Sumitomo Rubber Industries’ own research (September 2023)

*2 Part of the products released

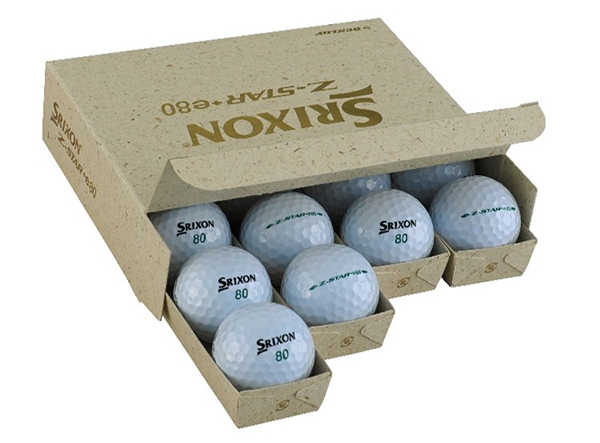

We are also committed to environmental sustainability in our golf balls. In November 2025, we announced the “SRIXON Z-STAR +e80” (non-commercial product), featuring an 82% sustainable material ratio.This product achieves performance nearly equivalent to the “SRIXON Z-STAR ◆ DIAMOND,” while increasing the proportion of sustainable raw materials by approximately 70 percentage points compared with the “SRIXON Z-STAR +e.” <sup>*1 </sup>

For the synthetic rubber, the primary raw material in golf balls, we use a product manufactured via the ”mass balance method"<sup>*2</sup>. For the crosslinking agent used to enhance the rubber's strength and elasticity, we employ zinc diacrylate derived from plant-based materials. Furthermore, we incorporate recycled material sourced from golf ball waste and blend corn-derived bio-polyol into the cover. Recycled carbon fiber is extracted and milled<sup>*3</sup> by partner companies and incorporated into the core layer of this product. The packaging uses paper that incorporates grass and grain fibers as a substitute for wood pulp in part of the raw materials, reflecting environmental considerations. Furthermore, the shape has been evolved from the “SRIXON Z-STAR+e,” reducing paper usage.

The packaging uses paper that incorporates grass and grain fibers as alternatives to wood pulp in part of its raw materials, reflecting environmental considerations. Furthermore, by evolving the shape from the “SRIXON Z-STAR+e,” paper usage has been reduced.

Moving forward, under our long-term sustainability Targets “Driving Our Future Initiatives” we will accelerate initiatives toward achieving carbon neutrality across the entire supply chain and realizing a circular economy, contributing to the development of a sustainable society.

*1 Developed the environmentally conscious concept golf ball “SRIXON Z-STAR+e” (DUNLOP SPORTS STYLE Latest News: November 30, 2023)https://sports.dunlop.co.jp/updates/detail/20231127133258.html

*2 A method where, during the processing and distribution stages from raw materials to finished products, when raw materials possessing certain characteristics (e.g., biomass-derived or recycled materials) are mixed with raw materials lacking those characteristics (e.g., petroleum-derived materials), the characteristics of the former are allocated to a portion of the product based on the input quantity of the characteristic-bearing raw material. (Ministry of the Environment: Bio-based Plastics Introduction Roadmap) For example, when producing 100 products using 70 kg of fossil-derived raw materials and 30 kg of biomass-derived raw materials, applying the mass balance method allows 30 of those products to be treated as “100% biomass-derived.” Without the mass balance method, 100 products would each contain 30% biomass-derived raw material.

*3 Carbon fiber that has been cut into short lengths and pulverized into a powder form.

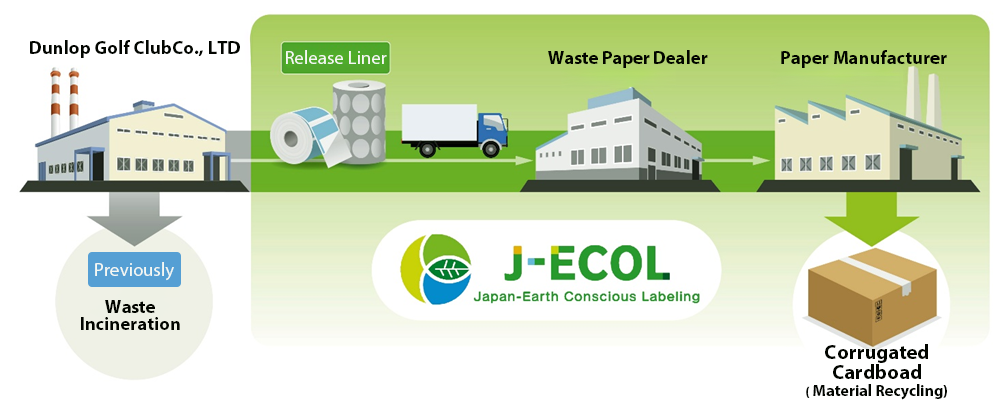

As our group's first initiative, we began material recycling*1 of label backing paper generated at our affiliate, Dunlop Golf Club Co., Ltd., in December 2025. In collaboration with the Japan Earth Conscious Labeling Association (J-ECOL)*2, we are recycling label backing paper—previously incinerated—as part of the raw material for corrugated cardboard (core material).

Label backing paper refers to the paper left behind after labels or stickers are peeled off. Due to silicone or polyethylene coating on its surface, it is treated as a “prohibited material” difficult to recycle as paper raw material, with incineration or thermal recycling*3 being the mainstream disposal methods.

With J-ECOL's support, we established a material recycling supply chain that would have been difficult to achieve independently. Label backing paper is properly sorted within the factory and collected by waste paper dealers. It is then recycled as raw material for recycled paper, ultimately being reborn as corrugated cardboard (core material). By reusing label backing paper as a valuable resource, we contribute to reducing CO2 emissions from its incineration and to realizing a circular economy.

*1 A method of reusing waste as raw material for new products

*2 Japan Earth Conscious Labeling Association(J-ECOL) Website https://www.j-ecol.or.jp/program

*3 A method of reusing the heat generated during waste incineration as energy