The Sumitomo Rubber Group emphasizes conducting sustainable business activities in harmony with society and the environment. To drive the realization of its corporate strategies, the group established a new corporate philosophy system, “Our Philosophy,” in December 2020, defining its Purpose as “Through innovation we will create a future of joy and well-being for all.”

This Purpose serves as the foundation for all decision-making and actions, guiding the group to strive for not only economic value but also the enhancement of social value, ultimately contributing to the development of a sustainable society.

To realize this corporate philosophy, our Group identifies Material Issues by considering risks and opportunities across the entire value chain. Among these, “Climate Change,” “Biodiversity,” and “Circular economy” are closely interrelated. We believe a comprehensive approach, rather than isolated measures, is essential and are advancing our initiatives accordingly.

Our Group recognizes that our business activities impact climate change through greenhouse gas emissions, including CO2, and energy consumption. Alongside mitigation efforts to minimize this impact as much as possible, we are also focusing on adaptation—preparing for risks brought by climate change and maximizing opportunities.

Climate change is a shared challenge for humanity. To pass on a better global environment to future generations, our Group must also tackle this issue. Guided by our Purpose—“Creating the ultimate peace of mind and joy through innovation that opens the future”—we will continue to pursue forward-looking challenges for our Group's sustainable growth and the realization of a sustainable environment and society.

At the core of our group’s efforts lies the Sustainability Management Promotion Headquarters, working in unison with top management and various departments to advance integrated environmental management initiatives. To further sustainability management, the “Sustainability Promotion Committee,” chaired by the Executive Director in Charge of Sustainability and joined by officers in charge of respective divisions, meets twice annually. This committee ensures thorough company-wide policy implementation and monitors progress on material issues.

Under the committee, the Sustainability Promotion Working Group (WG) has been established. Among its initiatives, the Carbon Neutral Subcommittee operates as a cross-functional team to drive progress in this crucial area.

In June 2021, our Group declared its support for the TCFD recommendations. Concerning both risks and opportunities that climate change poses to our business, we have moved forward with information disclosure based on the following four basic elements: governance, strategy, risk management, targets and indicators.

Climate change risks have been identified as one of our material issues, necessitating detailed analysis. Following the TCFD declaration, we have assessed the business impacts through analysis of 4℃ and 1.5/2℃ scenarios. In 2024, we revisited and reorganized our strategies for dealing with these risks and opportunities.

Our Group aims to achieve carbon neutrality for Scope 1 and 2 emissions by 2050. To realize this, we are working to reduce CO2 emissions from fuel consumption and electricity use associated with our business activities. We are promoting improved energy efficiency through energy conservation and the utilization of alternative fuels such as hydrogen. Furthermore, across the entire lifecycle—including procurement, logistics, and manufacturing—the Group is advancing initiatives focused on reducing environmental impact, accelerating effective responses to mitigate climate change.

Our Group is also focused on preparing for risks posed by climate change and maximizing related new opportunities. We aim for sustainable growth while enhancing business resilience through measures such as building BCPs to improve our ability to respond to extreme weather events, developing technologies that contribute to reducing environmental impact during operation, and efficiently managing water resources.

For details on risks and opportunities, please refer to the page “Information disclosure aligned with the TCFD and TNFD recommendations"

For details on risk management within our Group, please refer to the following link.

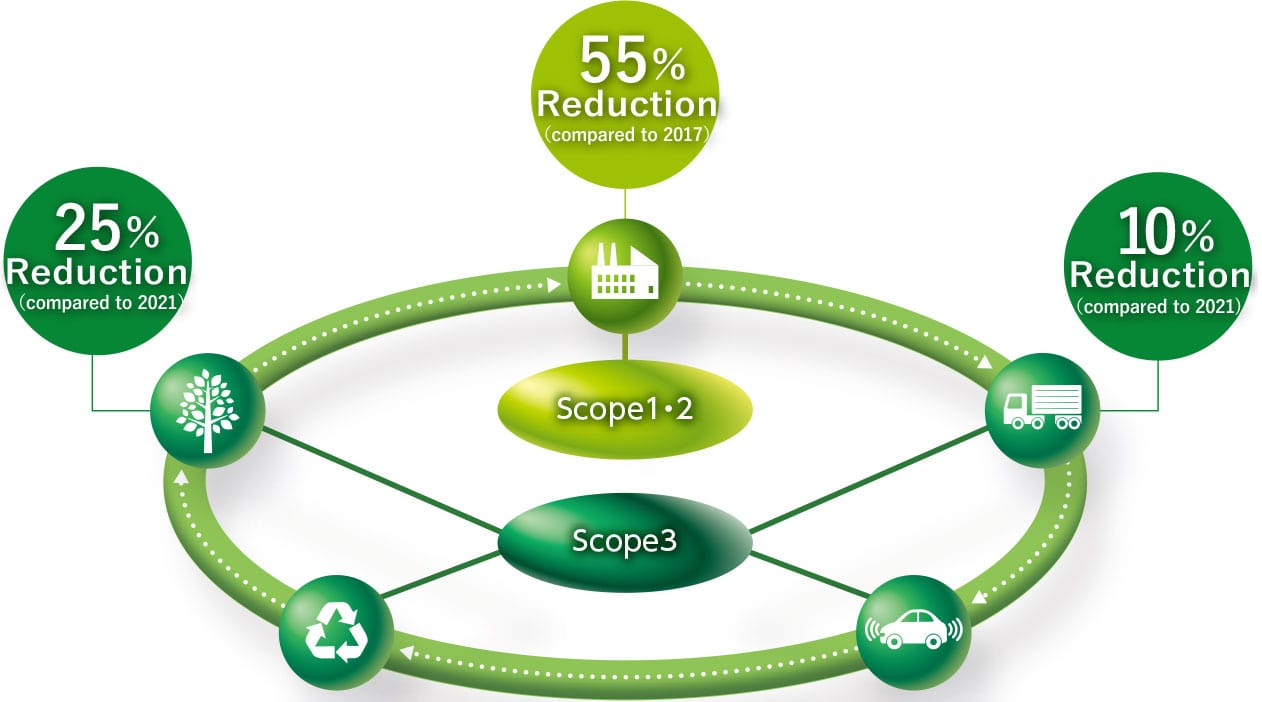

The Group has set a goal of achieving carbon neutrality (Scope 1 and 2) by 2050 and formulated a scenario for reducing CO2 emissions based on the actual energy consumption at each site. The initial target of a 50% reduction by 2030 (compared to 2017 base year), set in our Long-Term Sustainability Targets, “Driving Our Future Initiatives,” has been raised to a 55% reduction due to the proactive efforts at each of our sites. Additionally, approximately 97% of our Group’s CO2 emissions fall under Scope 3. To achieve carbon neutrality across the entire supply chain, we have set a 2030 target to cover approximately 80% of Scope 3 emissions. For Category 1 (Material Development and Procurement), we aim to reduce emissions by 25% by 2030 (compared to 2021 base year) by strengthening supplier engagement. For Category 4 (Logistics), we aim to reduce emissions by 10% by 2030 (compared to 2021 base year) through efforts such as promoting modal shift. In addition, for Category 11 (Sales and Usage) and Category 12 (Recovery and Recycling), we will make efforts to reduce the rolling resistance of tires, extend the lives of tires, and expand the production capacity of retread tires. We will aim to achieve these targets by promoting initiatives outlined in “Driving Our Future Initiatives 2050” and the circular economy concept for the tire industry:“TOWANOWA.”

| 2030 Target | 2024 Emissions (t-CO2) | 2017 base year | Main Reduction Measures | |

|---|---|---|---|---|

Scope 1 and 2

|

55%reduction (base year 2017) |

681,269 | 35%reduction | Installation of energy-saving facilities, expansion of cogeneration systems, introduction of solar power generators, and shift to green energy procured from renewable energy sources |

* In 2017, CO2 emissions were calculated using location-based emission factors, while in 2024, the reduction ratio was derived from CO2 emissions calculated using market-based emission factors.

| 2030 Target | 2024 Emissions(t-CO2) | 2021 base year | Main Reduction Measures | |

|---|---|---|---|---|

Category 1

「Purchased goods/services」 |

25%reduction (base year 2021) |

4,454,962 | 12%reduction | Use of sustainable raw materials and strengthening engagement with suppliers |

Category 4

「Upstream transportation and distribution」 |

10%reduction (base year 2021) |

364,144 | 3%reduction | Promotion of modal shift and optimization of logistics systems |

Category 11

「Use of sold products」 |

Setting KPIs | - | 15%reduction | Reduction of tiresʼ rolling resistance, longer tire life, and lighter tire weight |

Category 12

「End-of-life treatment of sold products」 |

Setting KPIs | - | 16%reduction | Increased production capacity of retreading tires, lighter tire weight and use of sustainable raw materials |

* CO2 emissions are calculated using emission factors from IDEA ver. 2.3.

*The calculation methods for baseline emissions for 2021 was reviewed in February 2026, and progress toward the Category 1 target was updated accordingly.

|

Item

|

Details

|

Reference Information

|

|---|---|---|

|

Acquisition of SBT Certification

|

The Sumitomo Rubber Group received certification for its GHG emissions reduction targets for 2030 from the Science Based Targets Initiative (SBTi) based on the recognition that our reduction targets are consistent with scientific evidence. |

Sumitomo Rubber’s Greenhouse Gas Emission Reduction Targets Acquire SBT Certification |

|

RE100

|

The Company announced that it has officially endorsed “RE100,” an international environmental initiative that brings together companies all over the world with the shared aim of transitioning to 100% renewable energy for all of their electric power needs. |

Sumitomo Rubber Joins the RE100 International Environmental Initiative |

|

Participation in the Japan Rubber Manufacturers Association

|

To implement our approach and strategies for climate change actions in alignment with industry trends, we participate in the Japan Rubber Manufacturers Association. In addition, we are actively engaged in the Keidanren (Japan Business Federation) Carbon Neutrality Action Plan.We will regularly verify the alignment between our climate change strategy and the positions of the industry associations we belong to. Should any discrepancies or shortcomings be identified, we will consider reviewing our relationships as necessary. |

Environmental Initiatives | JRMA The Japan Rubber Manufacturers Association |

In 2024, in addition to our existing investment criteria, we identified mitigation and adaptation priorities to address climate change risks (including transition risks) and established internal sustainability-related investment criteria, taking into account the actions of other companies and market conditions. In 2025, we will incorporate sustainability-related investments into our business and financial plans based on these criteria. Additionally, we have allocated a budget for an environmental performance data management system, including CO2 data, and are actively involved in data analysis and management. As we advance, we will continue to enhance our data analysis and management capabilities to strengthen our efforts to reduce CO2 emissions.

|

Item

|

Our Approach

|

|---|---|

|

Scope 1 and 2

|

We are advancing initiatives such as installation of energy-saving facilities, expansion of cogeneration systems, introduction of solar power generators, and shift to green energy procured from renewable energy sources. Through these measures, we are promoting the reduction of CO2 emissions across the entire Group. In particular, we recognize that achieving carbon neutrality in the fuels used to generate steam is a critical challenge in reducing Scope 1 emissions. To this end, we are collaborating with industry, academia, and government to establish and develop technologies for utilizing new energy sources, such as hydrogen. We aim to implement decarbonization initiatives, including fuel conversion, while closely monitoring developments in infrastructure and technological innovation from 2030 onwards. |

From August 2021 to March 2024, at our main tire factory, the Shirakawa Factory in Fukushima Prefecture, we conducted a demonstration project for utilizing hydrogen, which is expected to be a next-generation energy source. This project was supported by a subsidy program of the New Energy and Industrial Technology Development Organization (NEDO).

Besides introducing hydrogen energy, we installed solar panels in the employee parking lot, and in January 2023, we began mass production (Scope 1 and 2) of the carbon-neutral tires using hydrogen energy and solar power for the first time in Japan*1.

*1 Based on Sumitomo Rubber Industries’ research (as of January 2023)

Since January 2023, the Shirakawa Factory has been manufacturing tires using steam generated by hydrogen boilers, achieving reductions in CO2 emissions at the facility. However, the hydrogen used was derived from natural gas and procured externally via transportation, meaning it did not reduce CO2 emissions across the entire lifecycle.

In May 2024, we held a ceremony to sign a basic agreement with Yamanashi Prefecture, which is promoting advanced initiatives in hydrogen utilization, with the aim of mutual cooperation to promote decarbonization, including tire manufacturing, and to build a hydrogen energy society utilizing local resources.

As part of this collaboration, we introduced the “Yamanashi Model P2G System (hydrogen production equipment using water electrolysis)” developed by Yamanashi Prefecture and others, and began operation in April 2025. *1 Operating 24 hours a day, it can produce up to approximately 100 tons of hydrogen per year, enabling us to replace most of the hydrogen used in our hydrogen boilers with green hydrogen. This has resulted in a reduction of approximately 1,000 tons of CO2 emissions per year across the entire supply chain, including transportation (Scope 1, 2, and 3*2).

*1Introduction of Hydrogen Production System at Shirakawa Factory ~Start of 24-hour hydrogen production

*2: Scope 1 (direct emissions), Scope 2 (indirect emissions: electricity, etc.), Scope 3 (other indirect emissions: raw material procurement, transportation, etc.)

In 2022, we switched to renewable energy at two Chinese factories (Changshu and Hunan) in January, and then at another Chinese factory (Zhongshan), some domestic affiliates, and the Turkey factory. In 2023, we are planning to also switch to renewable energy at our Brazil Factory, Kobe Head Office, Tokyo Head Office (office building only), Thailand Factory, and Indonesia Factory. Furthermore, the Thailand Factory is planning to implement a cogeneration system and install the world’s largest rooftop solar power generation system.

|

Item

|

The approach

|

|---|---|

|

Scope 3

|

Approximately 97% of the CO2 emissions generated by the entire supply chain of the Group are attributed to emissions from sources other than the Company (Scope 3), making reducing Scope 3 emissions a key challenge. Reducing Scope 3 emissions requires our efforts and collaboration with our suppliers, logistics operators, other companies, and industry organizations. Therefore, we will further enhance our CO2 reduction initiatives in collaboration with all relevant parties. |

Approximately 80%*3 of our Group's Scope 3 CO2 emissions are attributed to Category 1: “Purchased goods and services.” Therefore, we believe the cooperation of our suppliers is essential to reducing CO2 emissions across the entire supply chain.

In 2025, our Group aims to reduce CO₂ emissions in line with the 1.5°C Science Based Targets (SBT). We conducted a “2025 CO2 Emissions Survey Briefing” targeting suppliers of tire raw materials, which account for approximately 95% of our CO₂ emissions. We also initiated engagement with some of these tire raw material suppliers.

During the briefing, we explained the background of the Paris Agreement and examples of CO2 reduction measures. We also requested the provision of primary data※4 and sought their understanding and cooperation.

The engagement aims not to unilaterally demand decarbonization efforts but to advance CO2 reduction initiatives collaboratively with our suppliers, valuing dialogue. We are confirming the status of our suppliers' CO2 reduction efforts through interviews.

Moving forward, we will proceed with the internal replacement process using the primary data received from our suppliers. We will then collaboratively implement CO2 reduction measures aligned with actual conditions, aiming for carbon neutrality across the entire supply chain.

*3 Excludes Category 11 “Use of Sold Products,” which corresponds to indirect emissions

*4 Primary Data: Actual CO₂ emissions data calculated by our business partners. This allows us to understand emissions based on actual conditions rather than industry averages or estimates, enabling the implementation of effective reduction measures.

We are advancing the development of sustainable raw materials in collaboration with other companies, contributing to the reduction of CO2 emissions across the entire supply chain.

Please refer to the link below for more information on climate change measures through collaboration with other companies.

In 2024, as a result of examining low-CO₂ transportation methods and assessing actual conditions, we established a company-wide reduction policy for Category 4 emissions by 2030.

In 2025, we held explanatory meetings on this policy for some of our sites and requested the creation of reduction scenarios. Going forward, we will refine the submitted scenarios and expand this initiative to all targeted sites. We will collaboratively examine specific reduction measures and associated costs, taking regional characteristics into account, aiming to achieve the 2030 target.

Regarding CO₂ emissions calculation, we have begun exploring the use of primary data※4 to accurately capture actual emissions. Moving forward, we will collaborate with logistics providers to develop efficient data collection methods and explore future reduction measures.

Our group will promote sustainable logistics and contribute to realizing a sustainable future.

*4 Primary data: Actual CO₂ emissions data calculated by our business partners. This enables us to grasp emissions based on actual conditions rather than industry averages or estimates, making it possible to implement effective reduction measures.

Although some years saw CO2 emissions below the previous year due to changes in sales composition, we continue striving to improve the modal shift rate to reduce CO2 emissions.

In fiscal year 2024, we were certified as an “Eco Ship Mark Excellent Operator” by the Eco Ship Modal Shift Project Executive Committee for our contribution to modal shift toward maritime transport as a shipper. This route previously involved regular shipments between the Kanto/Tohoku regions and the Kyushu region using large trailers operated by Shoei Co., Ltd. However, we shifted the entire volume to transportation by Tokyo Kyushu Ferry Co., Ltd.

The Group is working to reduce CO2 emissions across society by promoting technical innovation and significantly reducing environmental impact throughout the entire tire life cycle.

We calculate CO2 emissions (Scope 1, 2, and 3) and set reduction targets for them as part of our environmental goals. Additionally, we quantify CO2 reductions achieved through measures such as reducing rolling resistance in tires as reduction contribution, engage in dialogue with relevant internal and external departments to assess the extent of CO2 emissions reductions during tire use, and continue to work toward realizing a sustainable future.

CO2 emissions over the life cycle of tires occur when fuel is combusted during vehicle operation. Our Group contributes to reducing CO2 emissions by decreasing tire rolling resistance in Category 11, “Use of sold products (indirect use-phase emissions),” thereby enhancing vehicle fuel efficiency. Additionally, under Category 12, “End-of-life treatment of sold products,” We are working to reduce CO2 emissions by promoting a circular economy, including extending the lives of tires, expanding the production capacity of retread tires, and promoting their use.

Furthermore, we are contributing to reducing CO2 emissions generated by our customers by developing and expanding fuel-efficient tires equipped with our SMART TYRE CONCEPT (STC). This innovative tire technology combines environmental performance with driving performance. In October 2024, we launched SYNCHRO WEATHER, a tire that offers the performance of both summer and winter tires in a single model. This contributes to reducing CO2 emissions by conserving resources in tire manufacturing and minimizing waste tire generation.

We are implementing environmental awareness-raising activities, including study sessions, to deepen the understanding of each employee regarding environmental issues and to encourage them to actively participate in environmental conservation initiatives. In 2022, as a company-wide initiative, we set up Carbon Neutral Hub on the Sumitomo Rubber website, where we provide information on our initiatives for carbon neutrality and environmental information in video format. Furthermore, as a way of raising awareness among younger employees and getting them to think about the global environment of the future, we hold training programs and roundtable discussions on carbon neutrality for new employees.

Since 2023, we have utilized the event platform of the Dunlop Phoenix Tournament, one of Japan's premier golf tournaments, to exhibit an SDGs booth.

At the 2024 SDGs booth, we demonstrated the capture of atmospheric CO₂ using the technology of “metacol,” a future material developed by Sumitomo Electric Industries, Ltd. that solidifies CO₂. Additionally, at the Osaka-Kansai Expo “Sumitomo Pavilion,” we exhibited and sold SRIXON brand golf tees and markers jointly planned by our company and Sumitomo Electric Industries, Ltd.

These products were manufactured using CO₂ captured from the atmosphere as raw material, utilizing “metacol.”

We will continue to broaden understanding of climate change and contribute to realizing a sustainable society through various events and information dissemination.