The Sumitomo Rubber Group strives to reduce the environmental impact caused by chemical substances and other materials emitted from its business activities. Furthermore, we comply with international declarations and treaties concerning environmental conservation, as well as the laws and regulations of the countries and regions where our Group conducts business.

For governance, please refer to the link below.

For strategy, risks, and opportunities, please refer to the link below.

Our group periodically reviews risks in response to changes in the business environment. To reduce the environmental impact arising from our business activities, we continuously monitor through the EMS Subcommittee and TRWP Subcommittee established under the Sustainability Promotion Committee, share information with relevant parties, and respond appropriately. Furthermore, if a significant risk materializes or is anticipated to materialize, we will establish a Crisis Management Headquarters based on our crisis management regulations.

The targets and results are as follows.

| 2025 target | ・Participation in TIP(Tire Industry Project) activities ・Strengthen collaboration with external partners in the generation, dispersion, and accumulation phases of TRWP(Tire and Road Wear Particles) to deepen fundamental understanding and reduce environmental impact |

|---|---|

| 2025 result | ・Actively participate in TIP activities ・Present the results of each initiative at conferences such as Tyre Tech ・Issue a news release in August detailing the results of initiatives to date |

| 2026 target | ・Continuous and active participation in TIP activities ・Promote various joint research projects and publish the results obtained |

| Medium-to long-term target | Contributes to reducing environmental impact by suppressing the generation of TRWP and reducing tire energy loss. |

The Sumitomo Rubber Group is promoting initiatives to create a recycling-oriented society, and in 2013, we achieved zero direct landfill of waste at 23 production bases, including affiliates in Japan and overseas. We are continuing these efforts.

For a vehicle to operate, friction between the road surface and tires is essential. The dust generated by this friction is called TRWP, a mixture composed of tread components from tires and road pavement materials. We recognize that clarifying the characteristics of TRWP and its environmental impact, and reducing that impact, is a challenge for our company.

Our company has long worked to reduce TRWP generation by enhancing tire wear resistance. In recent years, as a further approach, we have focused on the three stages of TRWP: ① generation, ② dispersion, and ③ accumulation. Regarding the mechanism of “① generation,” we are aiming to develop technologies that suppress TRWP generation by approaching the issue from both the tire and road surface perspectives. For suppressing “② dispersion,” we are working on developing a TRWP recovery device that utilizes the airflow generated around the tire during driving. We have presented the results of these efforts at academic conferences both in Japan and internationally.

We participate in the TIP<sup> ※2</sup>(a global tire manufacturer consortium of 10 companies), advancing research on TRWP, establishing evaluation methods, and engaging in dialogue with stakeholders.

Additionally, domestically, we are active as members of the Japan Automobile Tyre Manufacturers Association, Inc.

(JATMA<sup>※3</sup>) and the Japan Rubber Manufacturers Association (JRMA<sup>※4</sup>), working on the creation of ISO standards for TRWP evaluation.

※1 Tire and Road Wear Particles

※2 Tire Industry Project

※3 The Japan Automobile Tyre Manufacturers Association, Inc.

※4 The Japan Rubber Manufacturers Association

6PPD (N-(1,3-dimethylbutyl)-N'-phenyl-para-phenylenediamine) is a widely used anti-aging agent in the tire industry. Recently, studies suggesting that 6PPD-quinone, formed when 6PPD reacts with oxygen or ozone in the environment, may be harmful to certain aquatic organisms have been published. This has triggered regulatory procedures in the United States.

However, 6PPD itself plays a crucial role in preventing surface cracking on tires caused by the reaction between oxygen or ozone in the environment and rubber, thereby inhibiting the progression of deterioration. Therefore, 6PPD is an essential material for tires to fully demonstrate their performance and for customers to use them safely and for a long time. Currently, the entire tire industry is working to explore the potential of alternative technologies and to develop and evaluate substitutes. As a member of this effort, our company is also actively advancing these initiatives.

It has been pointed out that even in sports artificial turf, broken turf and infill rubber chips may leach into rivers and oceans over time, potentially becoming microplastics※1. Since 2020, our company has been working to confirm the extent of this leakage and develop materials and products with high leakage suppression effectiveness. Currently, we are proposing measures to artificial turf facility operators, such as confirmed suppression-effective layouts for the outer perimeter of turf and installing filter materials in drainage ditches. Gradually, these leakage suppression measures are being implemented.

We will continue to advance the development and improvement of runoff suppression technologies while promoting the adoption of these countermeasures. Furthermore, our efforts have been featured in an introduction article by the Ministry of the Environment※2 and are also referenced in guidelines※3※4 for microplastic countermeasures originating from artificial turf, issued by local governments.

※1 Tiny plastic particles smaller than 5mm

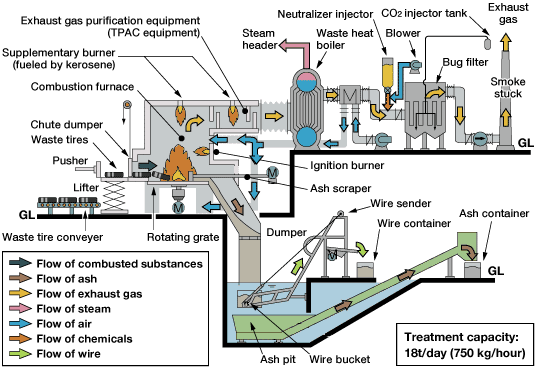

The Sumitomo Rubber Group is actively working to reduce environmental impact by promoting the recycling of ELT(End of Life Tires). As part of our circular economy initiatives, we promote the use of ELT for retreading and their reuse as raw materials (material recycling). At the same time, we have also implemented a thermal recycling system at our tire factory, using ELT as boiler fuel to efficiently harness them as an energy source.