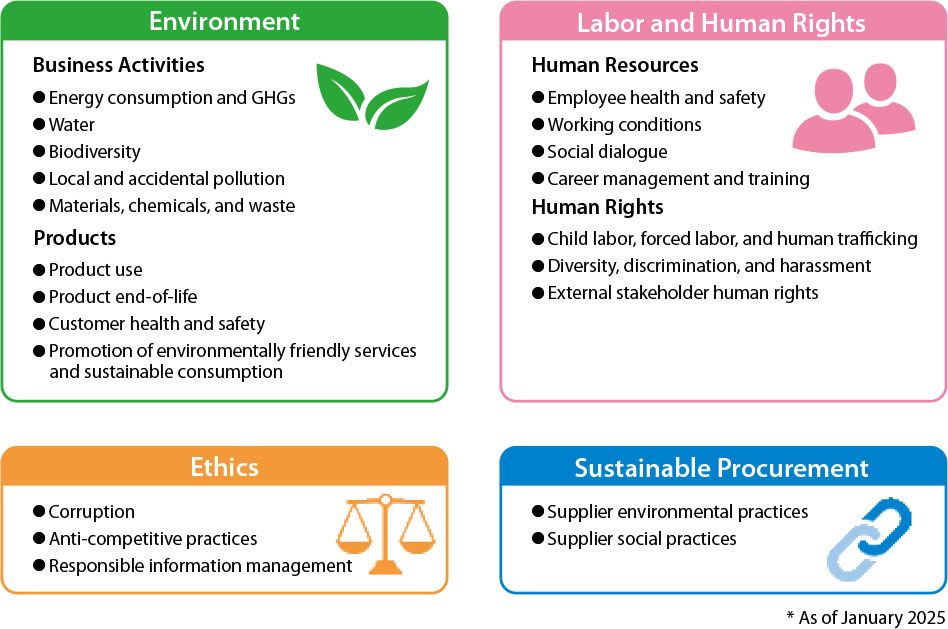

The Sumitomo Rubber Group aims for fair and transparent corporate activities, striving to be a good partner to our suppliers. To that end, we pursue sustainable procurement through initiatives such as formulating and implementing Procurement Guidelines and their revision in response to legal amendments or changes in the external environment.

We will strengthen cooperation with suppliers and sales companies, implement ESG initiatives from a global and medium-to long-term perspective, and accelerate the creation of a sustainable logistics system.

With the aim of realizing sustainable procurement, the Sumitomo Rubber Group updated its Procurement Guidelines to the 8th Edition in July 2024. We have changed our CSR Procurement Guidelines to Sustainable Procurement Guidelines, adding new items such as system support for digital transformation (DX) management, use of sustainable raw materials, and initiatives to achieve carbon neutrality.

We ask our suppliers to confirm their understanding of the Procurement Guidelines distributed to them. As of the end of January 2025, approximately 90% of our tire raw material suppliers have signed and submitted a letter of acceptance confirming their understanding of the guidelines.

To achieve sustainable procurement, we explain the following seven points to our suppliers.

1)Building sustainable relationships with suppliers: Aiming for sustainable procurement and new partnerships through strengthening BCP and supply chain collaboration, conducting sustainability assessments, etc.

2)Procurement activities utilizing digital technology: Responding to digitization and the accompanying systemization for DX management

3)Natural rubber: Our initiatives on issues related to the environment and human rights in producing natural rubber, which is the primary raw material for tires, etc.

4)Efforts to maintain and improve quality: Our Group’s quality policy, establishment of quality management systems, and management of changes, applications, and procedures

5)Sustainable use of raw materials: Circular economy concept for the Tire Business, sustainable raw material targets, promotion of activities, etc.

6)Considerations for the environment: Initiatives to achieve carbon neutrality, management of environmentally hazardous substances, and symbiosis with nature (forest conservation, consideration for biodiversity), etc.

7)Social and governance: Respect for human and fundamental labor rights, thorough compliance and information management, risk reduction through risk assessment, etc.

Procurement Guidelines 8th Edition [Raw materials for tire](WEB Edition)(Japanese)

Procurement Guidelines 8 Edition 【Raw materials for tire】 Web Edition

Diretrizes de aquisição 8ª Edição [Para matérias primas de pneus](Versão Web)

Pedoman Pengadaan Edisi ke-8 [Bahan baku mentah untuk ban](Edisi Web)

แนวทางการจัดซื้อจัดจ้าง ฉบับที่ 8 [ส าหรับวัตถุดิบยางรถยนต์](รูปแบบอิเล็กทรอนิกส์)

To efficiently monitor and assess human rights, governance, and environmental performance within our supply chain, we have been working with EcoVadis, an international third-party assessment organization, since January 2022. EcoVadis operates a platform for sustainability assessment, evaluating suppliers based on sustainability standards.

For new suppliers as well, we perform due diligence in a similar fashion, with an emphasis on assessing and mitigating corruption risks. If the results of our due diligence and assessment of a supplier fail to meet certain criteria, we ask that they make improvements. As a result of working with EcoVadis, the assessment criteria have been standardized, and we expect our assessment results and improvement recommendations to help our suppliers pursue sustainability efficiently.

We have been implementing Green Logistics Guidelines since 2007 to promote initiatives to reduce CO2 emissions in the logistics stage by improving our logistics system. We accurately grasp customer and market demands and reliably deliver products that meet those demands, while also considering the global environment and conducting green logistics activities with our suppliers.

In recent years, the risks associated with business operations have become increasingly diverse, including the risk of natural disasters caused by climate change and cybersecurity risks. Additionally, supply chains have become more complex, and the damage caused by risks becoming apparent has become more severe, increasing the risk of supply chain disruption. We believe it is crucial to proactively identify and address potential risks in the procurement domain, implement measures to mitigate or eliminate such risks as much as possible, and achieve stable and sustainable procurement.

Risks

・Increased investment toward achieving carbon neutrality by 2050, a goal set by more than 120 countries and regions, including Japan

・Loss of trust among stakeholders such as investors and customers due to the failure to achieve the target of reducing CO2 emissions by 10% by 2030 compared to 2021 base year despite the increase in sales volume

・Differences in responses among suppliers

・Differences in responses among suppliers

Opportunities

・Becoming a preferred shipper for transportation and warehousing companies

・Enhancing brand value through an environmentally conscious corporate image

・Taking advantage of tax incentives, subsidies, and support programs

To ensure that our procurement activities respond quickly to rapidly changing social conditions, we have launched a Sustainability Committee within the Procurement Headquarters to hold regular discussions on procurement risks. The risks identified and discussed at the committee are reflected in our risk assessment items and used in formulating our procurement strategy. These activities also raise risk awareness among member of the Procurement Headquarters

・To reduce CO2 emissions, we are working company-wide (in cooperation with the Sustainability Management Promotion HQ) to confirm actual emissions, identify measures, and check progress at each base of operations.

・To build a stable logistics system, we are implementing measures to reduce truck drivers’ working hours and the workload of cargo handling at warehouses.

For information on CO2 reduction in procurement, please refer to the Climate Change page.

As a benchmark for ensuring that we can respond to risks associated with the procurement of tire raw materials, we have set a target of zero delivery problems (zero shortages of raw materials) that could affect production, such as a reduction in tire production.

| 2024 target | 0件 |

|---|---|

| 2024 result | 0件 |

| 2025 target | 0件 |

| Medium- to long-term target | 0件 |

Among the Long-Term Sustainability Policy goals, we have set a target of “procurement of 95% of tire raw materials by purchase value from suppliers who score at least 45 points on the standard evaluation by 2030.” in EcoVadis’ sustainability issue assessment.

| 2024 target | - |

|---|---|

| 2024 result | 97% |

| 2025 target | Maintain 95% or higher |

| Medium- to long-term target | Procurement of 95% of tire raw materials by purchase value from suppliers who score at least 45 points on the standard evaluation by 2030 |

Category 4: Logistics

After interviewing logistics companies about decarbonization measures, we will examine and implement transportation methods that emit less CO2, load export products at the port nearest the production factories, and reduce transfers between warehouses (reducing transportation weight), aiming to reduce CO2 emissions by 10% in 2030 compared to 2021 base year.

| 2024 targets | Exchanging opinions with domestic logistics companies on the feasibility of introducing /sub reduction measures and the possibility of sharing CO2 data Sharing information with overseas bases on local initiatives, company-wide targets, reduction measures, and the need for CO2 data sharing |

|---|---|

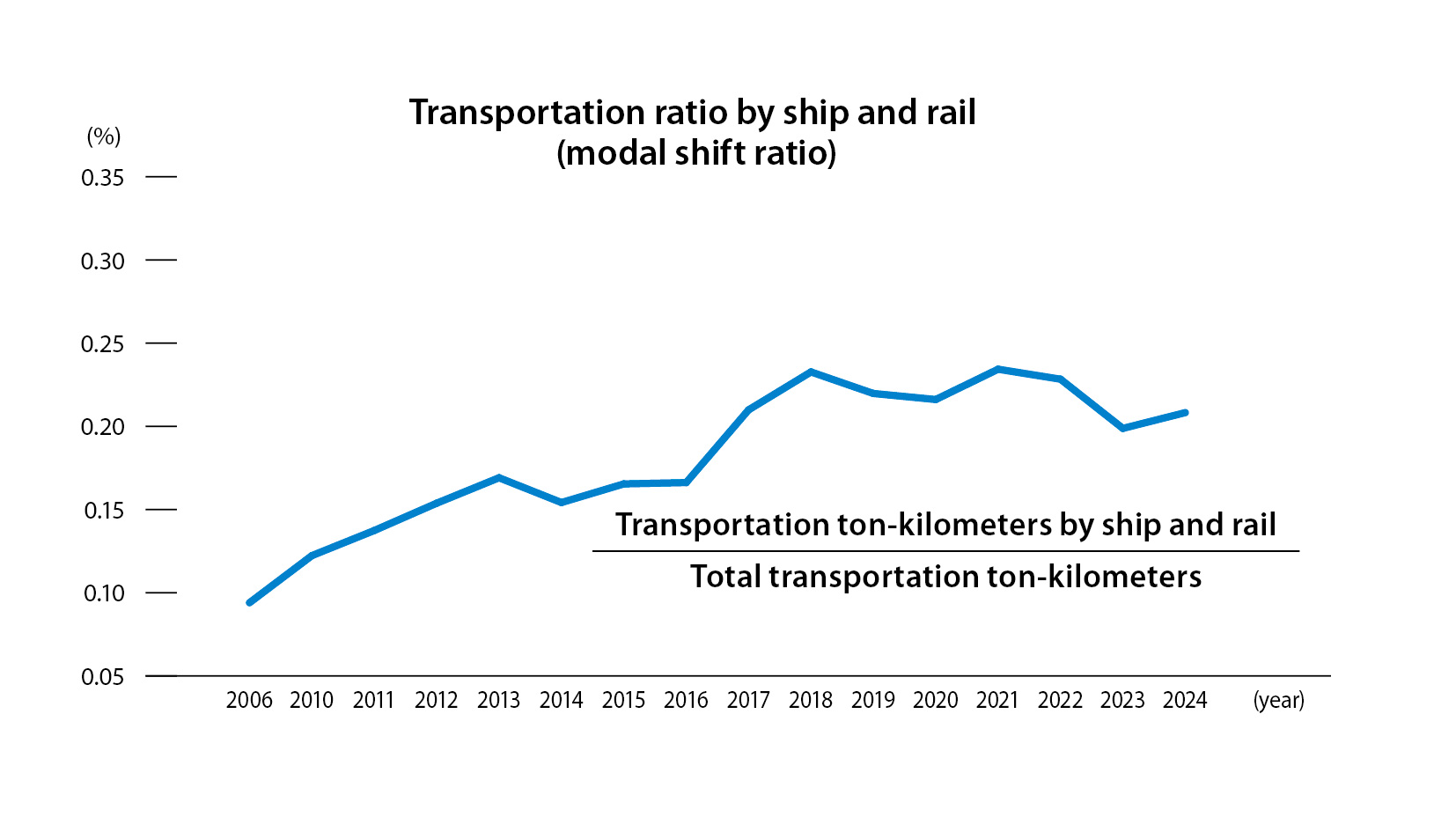

| 2024 results | Exchanging opinions with domestic logistics companies on the feasibility of introducing /sub reduction measures and the possibility of sharing CO2 data Sharing information with overseas bases on local initiatives, company-wide targets, reduction measures, and the need for CO2 data sharing Promoted modal shift (21% achieved), started joint delivery trials with other companies |

| 2025 targets | Exchanging opinions with domestic logistics companies on the implementation of CO2 reduction measures and methods for sharing CO2 data Sharing information on local initiatives, company-wide targets, and reduction measures with overseas bases, and beginning to share CO2 data Expanding modal shift, beginning full-scale joint delivery with other companies, and increasing shipping from the nearest port |

| Medium- to long-term targets | Reducing CO2 emissions by 10% by 2030 compared to 2021 base year in Category 4 |

To reduce the burden on drivers and warehouse workers, we have introduced an entry time reservation system, relay transportation, rack transportation, auto floor vehicles, clamp lifts, vanning and devanning belt conveyors, cargo handling robots, and vests with fans. We will continue to expand the implementation of measures to reduce the burden on logistics front lines.

Clamp lifts have enabled the mechanization of tasks previously performed manually, such as unloading truck and bus tires from trucks to warehouses or loading them from warehouses to lorries. This initiative reduces the workload and improves operational efficiency.

In 2024, we began discussions with some domestic suppliers regarding data sharing that will lead to CO2 reductions. We will expand the scope of this initiative in 2025 and beyond. In addition, we will discuss specific action plans with our overseas bases to achieve CO2 reduction targets.

To promote sustainable procurement activities, we hold briefings on our Procurement Guidelines for members of the internal Procurement Department and suppliers of tire raw materials to deepen their knowledge of sustainability and understanding of our activities. Furthermore, we are promoting global information gathering and decision-making initiatives and considering a shift to risk management utilizing digital technology to respond quickly to risks arising in a multi-layered and complex supply chain environment. We will continue to identify sustainability issues throughout the supply chain and promote initiatives to resolve them in collaboration with our suppliers.

To promote understanding of the contents of the revised 8th edition of our Procurement Guidelines, we held online briefings for suppliers at each of our tire raw material procurement bases (Europe, the US, China, Asia, and Japan) in July and August 2024. A total of 212 companies (585 participants) attended. A video of the briefing was distributed to all suppliers at a later date.

In June 2024, before the publication of the 8th edition of the Procurement Guidelines, we held a study session for the Group’s tire raw materials procurement staff. We explained the background and key points of the revisions to the Sustainable Procurement Guidelines to 38 members from each procurement base (Europe, the US, and Asia including China and Japan). We shared our guidelines, principles, and policies.

At a Global Meeting held once a year, procurement staff from each base of operations (Europe, the US, China, Asia, and Japan) gather to discuss sustainability issues, focusing on procurement risks related to tire raw materials, and formulate procurement strategies for each region and category based on the discussion. In 2024, the Global Meeting was held over two days from August 26 to 27.