Rooted in the Sumitomo Business Philosophy developed over 400 years, the Sumitomo Rubber Group is promoting various social contribution activities as a responsible corporate citizen. In particular, the “GENKI” (vibrant) volunteer projects that started as activities to help realize a society in which everyone can thrive have been carried out for over 30 years at business sites across the country. Through the GENKI Activities, we work with local communities where our business sites are located to carry out social contribution activities tailored to local needs. We will continue actively promoting initiatives such as the GENKI Activities, biodiversity conservation, and greening activities to achieve our Sustainability Vision and become a company that society trusts.

The Sumitomo Rubber Industries CSR Fund was established to provide financial assistance to NPOs working to solve global environmental and social issues, intending to support regional communities and foster coexistence within them.

Following its establishment in 2009, the Fund began providing grants in 2010 to organizations, including environmental advocates, traffic safety groups, disaster aid groups, and others striving to resolve region-specific social issues.

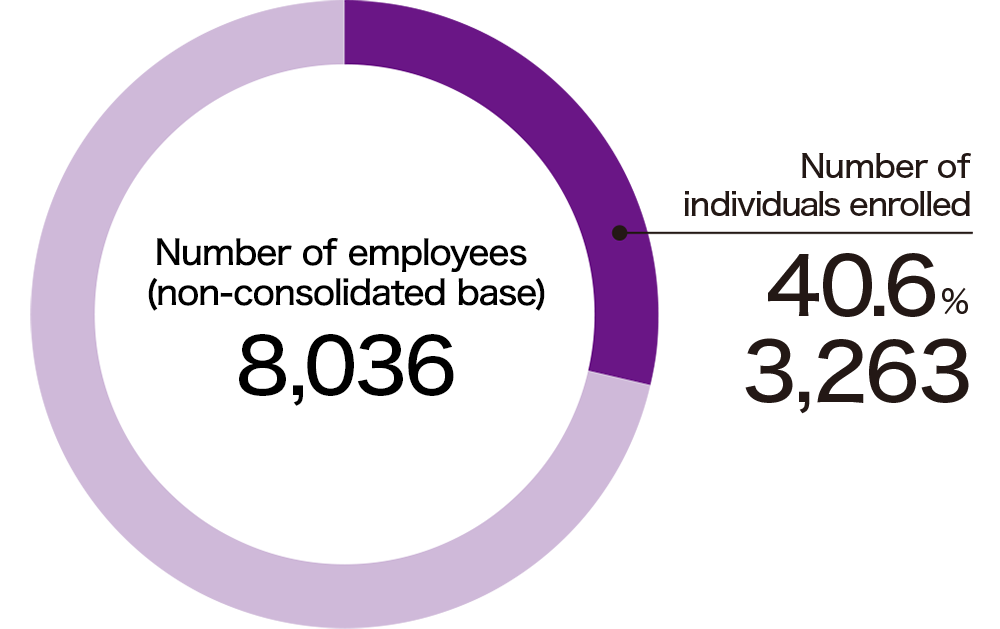

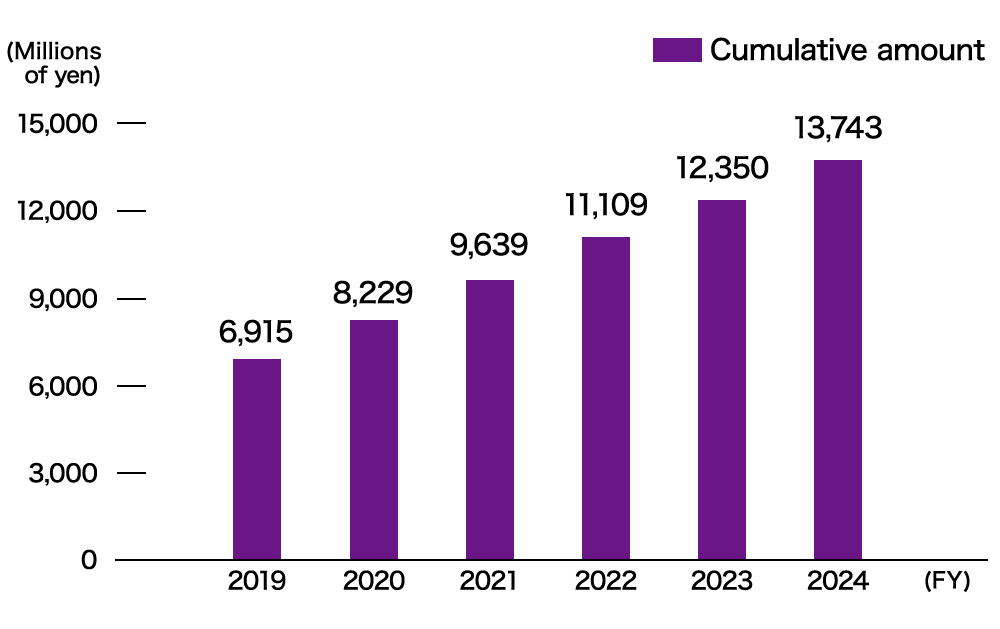

In fiscal 2024, we granted ¥13.90 million to 54 organizations, and total of approximately ¥137 million to 621 organizations.

The selection of grant recipients is based on whether their activities align with the Sumitomo Rubber Industries CSR Fund’s fundamental principles, which are rooted in our Sustainability Vision. To appropriately address the severity of the social issues being tackled and the specific needs of each local community, we primarily select organizations recommended by our business sites. We also evaluate the organization’s continuity, as the activities must allow for voluntary participation by our employees, and the support is intended for sound and sustainable initiatives.

We support organizations involved with various activities, including conducting volunteer thinning of abandoned forests in the mountainous areas of Toyota City, Aichi Prefecture, a society which works to protect rare species in Tamba City and an organization which runs activities in Kobe City to get children interested in the environment through science experiments.

Additionally, the Sumitomo Rubber Industries CSR Fund is utilized for donations to NGOs and NPOs engaged in disaster relief efforts and activities aimed at achieving the SDGs.

The Sumitomo Rubber Group values collaboration with diverse stakeholders. It implements social contribution initiatives that emphasize building strong, trusting relationships with the communities where we operate. By carrying out flexible social contribution activities tailored to the unique characteristics of each region, we not only fulfill our corporate social responsibility but also help create a work environment where employees feel secure and supported, leading to greater ease in their daily work and improved employee satisfaction. This also supports our growth as a company trusted by our communities.

We promote interaction and dialogue with diverse stakeholders by, for example, working in partnership with NGOs and NPOs. Through collaborative environmental activities such as cleaning nearby rivers and preserving satoyama (working forests that are maintained and managed by humans), we not only engage in social contribution efforts but also gain opportunities to better understand local social issues closely connected to the community. In addition, we encourage employee participation in volunteer activities by receiving information from local NPOs in the regions where our business bases are located.

Looking ahead, we will continue to create a place for both NPOs and our employees to encounter and learn from each other as part of efforts to expand the scope of partnerships.

At the Sumitomo Rubber Group, a dedicated contact in place at each business base, along with the General Affairs Department, is proactively playing a principal role in promoting communication and collaboration with local community residents and citizen organizations. We also endeavor to deepen relationships with local communities and, to this end, promote dialogue by, for example, inviting a diverse range of stakeholders to join factory tours and attend information exchange meetings so that they can understand our approach to manufacturing and appreciate our technologies. Through these dialogue initiatives, we strive to assess the impact of our business activities on neighboring communities and identify issues to be addressed while using the stakeholder perspective.

Stakeholder opinions and other inputs gleaned via dialogue are relayed to relevant departments as necessary and examined by the Management Meeting. We then provide each contact with feedback and otherwise utilize these inputs to improve our services and inform activities aimed at creating societal and economic value.

Promoting social contribution activities not only enhances our corporate image and strengthens support from consumers, investors, and business partners, but also boosts employee motivation, improves our evaluation among investors and suppliers, and helps build trust with local communities. Conversely, failing to promote such activities may pose risks in these areas.

We formulate annual plans and budgets to ensure the steady promotion of social contribution activities. In addition to deepening employee understanding and encouraging their active participation, we work to raise awareness of our initiatives and have established mechanisms to reflect employee input. These efforts also help secure personnel who can take an active role in implementing our social contribution activities.

The targets and results are as follows.

| 2024 target | Implementing social contribution activities that are tailored to local needs and emphasize engagement and dialogue with a wide range of stakeholders |

|---|---|

| 2024 result | Implemented community-based social contribution initiatives centered on the GENKI Activities (see the examples below for details) |

| 2025 target | Promoted next-generation development and educational support, along with social contribution activities tailored to local community needs |

| Medium- to long-term target | Supporting corporate growth by contributing to the realization of a sustainable society and earning the trust of society |

We have consistently continued our community-based social contribution initiatives centered on the GENKI Activities, successfully building strong relationships between each of our sites and neighboring residents. This year, we expanded our next-generation development initiatives, focusing on providing educational support to high schools. We believe that educational support not only enhances the capabilities of schools but also strengthens local communities and nurtures the future leaders of both the region and Japan—an essential contribution to realizing a sustainable society. In the next fiscal year, we will continue to actively promote next-generation development efforts and strive to be a company trusted by the local community.

In the course of promoting social contribution activities, the Sumitomo Rubber Group takes an approach that develops deep root in local communities surrounding its factories and other business bases. To this end, employees take the initiative to host events aimed at interacting with residents of these communities in order to create an environment conducive to mutual understanding and develop robust relationship of trust with them. Building on this relationship, we strive to resolve issues confronting each community.

The Nagoya Factory, which is based in Toyota City, Aichi Prefecture, cooperates with the municipality-led traffic safety campaigns that are held quarterly. Specifically, these campaigns involve factory staff who serve as volunteer patrol members standing in position with signs and banners along city roads, including in front of the factory gates and at major crossings within Toyota City, in order to encourage drivers passing by to observe safe driving practices. Meanwhile, employees at the Izumiotsu Factory formed a street observation team in 2010 to protect local children from traffic accidents. These employees take turns monthly to stand guard at three nearby crossings that children use when walking to school.

The Shirakawa Factory strives to contribute to the development of a safe environment in which children can play with an ease of mind. To that end, in 2013 staff at this factory began placing wasp traps at neighborhood kindergartens and childcare facilities. In 2022, the factory received a growing number of requests for the placement of such equipment from childcare facilities outside Shirakawa City. In response, factory staff placed wasp traps at a total of 12 such facilities. In this way, the factory cherishes relationships with neighboring community residents while continuously endeavoring to help create a safe and secure environment for them.

Previously, SRI Engineering, Ltd. had disposed of tooling board scraps generated in the course of manufacturing tire molds. Aware of the potential recyclability of these scraps as materials, the subsidiary considered various viable recycling methods. Consequently, in December 2017, SRI Engineering began providing these materials to educational institutions specialized in industrial and artistic design as well as to vocational training schools.

By April 2025, the subsidiary had provided tooling board materials free-of-charge on a total of 58 occasions, with the scope of recipients having expanded to comprise 29 educational institutions in Hyogo and other neighboring prefectures. By facilitating the reuse of waste materials, SRI Engineering aims to contribute to society in a sustainable manner.

In recognition of these initiatives, the subsidiary received a letter of gratitude from the governor of Hyogo Prefecture in October 2018. In November of the same year, SRI Engineering was also chosen to receive an Excellent Award under the Sumitomo Rubber Group CSR Commendation Awards Program. Going forward, SRI Engineering will continue to play its part in nurturing human resources by supporting young people who will, in turn, be the next generation of manufacturers.

In Hyogo Prefecture, vocational trainees at five vocational ability development schools are striving to enhance their machining techniques on a daily basis using tooling board materials provided free of charge. Meanwhile, students at Hyogo Prefectural Manufacturing College are similarly taking on the challenge of producing various prototypes in an effort to raise their skills. Today, the automation of manufacturing processes is progressing. However, it is also important for operators to gain real-life experience in creating tangible objects. This experience will better enable them to predict the actual shapes of target items while teaching them how to judge whether an item can actually be produced in line with a blueprint and detect small variances arising from the wear of machines or misalignment so that they can make on-site adjustments. Even amid the advance of automation in manufacturing, which now employs robots and AI, this experience will prove more crucial than ever before. I hereby express my wholehearted gratitude for the valuable materials that have been provided for use in training and will strive to nurture the human resources who are the future of manufacturing.

For Pink Ribbon Month”in October, we switch out the usual yellow brand color of the DUNLOP logo printed on the tires of racing cars and elsewhere for pink to help raise public awareness of the importance of early detection and treatment of breast cancer. Moreover, we display this pink logo on banners erected at racing tracks as well as on face masks and wrist bands worn by DUNLOP staff and offer stickers featuring this logo. In these ways, we endeavor to draw the attention of audiences to the Pink Ribbon Campaign at prominent racing events held during October.

Although people working in the motor sports industry, as well as the racing fans supporting it, are predominantly male, we believe that encouraging men to educate themselves about breast cancer is one of the important objectives of this campaign. Raising awareness among men will better equip them to urge their families, partners and relatives to undergo early checkups so that this disease, if present, is detected and treated earlier.

In 2024, we held the first kickoff event for the All Japan Kart Championship EV Division, which supplies DUNLOP tyres with a 43% ratio of sustainable materials. Kart racing, often considered a gateway into motorsports, has seen a growing number of female racing drivers in recent years. At this event, we conducted breast cancer awareness activities through a stage program and the exhibition of a DUNLOP booth.

In fiscal 2010, we began holding the Dunlop Environmental Class at schools and other institutions in Hyogo Prefecture in tandem with a NPO specializing in the environmental field. Designed to help children learn about environmental issues, such as global warming, and think for themselves about what they can do for the environment, the Dunlop Environmental Class involves on-demand lectures, as well as classes that allow them to participate in hands-on learning and various experiments.

In 2024, the Dunlop Environmental Class was held on a total of six occasions at two places, including a venue provided by a regional organization, with the number of participants totaling 165.

Since 2009, we have been a co-sponsor of the Dunlop Monozukuri Classes, an initiative led by NPO Core Net that offers hands-on manufacturing programs for fourth to sixth graders. At these events, children are given a simple set of parts to assemble a gadget called the “Scroller II.” These programs are designed to help children experience the excitement and fulfillment of manufacturing while also building teamwork.

By 2024, some 80 rounds of Monozukuri Classes had been held, with the total number of attendees reaching approximately 6,000.

These activities create opportunities for children in the community to learn about challenges of manufacturing. Children’s earnest efforts to learn something new serve as a driving force for us to continue these activities each year.

The Ichijima Factory, which produces golf balls, has been acting in collaboration with a local greening NPO, Kadono de Morimori Club, to support annual tree planting events to help fourth graders commemorate the joy of becoming teens. This collaboration also involves sponsoring workshops in which children can experience the planting and harvesting of wild rice varieties. Furthermore, the factory invites children from neighboring preschool facilities to observe the Sasakia charonda butterfly and to gather acorns. Through fun activities like these, we offer opportunities for children to become interested in topics related to the conservation of endangered plants and animals and the environment. The factory’s greening team is well-versed in maintaining lawn grass, which is essential to golfing, so its members can also cultivate Celtis sinensis, whose leaves are preferred by Sasakia charonda larvae. Taking advantage of their know-how on these matters, this team is also striving to assist its counterparts at other factories in their greening efforts. Moreover, when preschool children are invited into its premises, the factory opens its proving ground to them so that they can play on well-cared-for lawns.

Since 2022, the Kakogawa Factory has been donating Fujibakama (Eupatorium japonicum), an endangered species, plants cultivated on its grounds to neighboring elementary schools and providing on-demand lectures.

Furthermore, for kindergarteners about to graduate, we offer acorn seedlings that we have nurtured from the nut stage starting from the time of their entrance to the kindergarten as commemorative gifts. In these ways, we strive to secure public understanding of our activities while working hand in hand with people from local communities to promote greening initiatives.

Through various initiatives such as the “Job Experience Program” targeting junior high school students in Settsu City, Osaka Prefecture, the “Dunlop Corporate Training Program” for students in the Global Science Course at Kobe Ryukoku Senior High School, and the “Sword Project” exploratory learning program at Kansai University Hokuyo Senior High School, we are supporting career education for the next generation of children.

Meanwhile, in Thailand, the Sumitomo Rubber Industries CSR Fund helps support junior high school students in Udon Thani Province through the provision of scholarships.

As we aim to give back to society, we proactively make donations to and co-sponsor local events in regions where we have bases. In Japan, we have sponsored the “STOP! DRUNK DRIVING PROJECT” to eliminate drunk driving. We have also sponsored the KOBE MARATHON since its inaugural event as we align with its concept of communicating the appeal of Hyogo Prefecture and Kobe City and, as an area that experienced a disaster, the recovery process and lessons learned from the earthquake. Overseas, we donated uniforms to sports facilities for people with disabilities in Turkey and made donations to homes for elderly people in the Philippines. In China, we donated funds to support beautification projects. As these and other examples show, we strive to contribute to society through donations and co-sponsorship in regions across the globe.

Today, parasports are attracting growing attention from the general public. The Sumitomo Rubber Group is co-sponsoring various parasports events to help invigorate this sport category. In addition to a number of Group employees who volunteer their time and effort to help organize wheelchair tennis tournaments held in Aichi and Hyogo prefectures, Sumitomo Rubber Industries has been acting as a title sponsor of DUNLOP KOBE OPEN, an international wheelchair tournament, since fiscal 2009.

In 2012, we also began co-sponsoring the “Dream Maker Racing Project,” under which drivers with disabilities take on the challenge of running endurance racing, and providing racing tires for this project.

Going forward, we will continue engaging in these and other activities aimed at contributing to the creation of an inclusive society in which everyone can live in harmony irrespective of the presence or absence of disabilities.

In September 2013, the Sumitomo Rubber Group launched the Team ENASAVE Future Project to support the “Legacy for the Future” concept advocated by the National Federation of UNESCO Associations in Japan (NFUAJ). This project aims to ensure that Japan’s beautiful culture and nature are passed down to future generations for the next 100 years.

Starting this year, the name has been changed to “Team DUNLOP,” with DUNLOP taking over the activities previously carried out under ENASAVE. Together with customers who continue to use DUNLOP and its products, we will remain committed to environmental conservation efforts.

Unfortunately, due to the COVID-19 pandemic, we were unable to hold activities in 2020 and 2021. However, we resumed the activities in 2022, plan to hold activities in five locations in 2025.

For information on other dialogues, collaborations, and activities with regional communities, please check the following: