The Sumitomo Rubber Group bases all of its decision-making and actions on Our Philosophy, which is rooted in the Sumitomo Business Philosophy that has been passed down for nearly 400 years. With this principle, we have established Quality Policies based on our corporate philosophy of enhancing not only its economic value but also its societal value and contributing to the development of a sustainable society. We comply with all applicable laws and regulations and prioritize providing safe and attractive products, services, and solutions that meet customer needs. Our group’s Purpose, “Through innovation we will create a future of joy and well-being for all,” is precisely the pursuit of customer-oriented quality.

We hereby enact and shall henceforth put into practice the following Quality Policies based on our Corporate Philosophy, which espouses the ideals of contributing broadly to society by providing products and services that fulfill the needs of markets and customers while abiding by all applicable laws and regulations.

1)Provide products and services that earn the continued trust of customers while responding to the changing times through consistent practice of the “5-Gen* Principle.”

*5-Gen: Genchi (Actual Site), Genbutsu (Actual Objects), Genjitsu (Facts), Genri (Principles), Gensoku (Rules)

2)Create appealing products through innovation to pioneer the future backed by strong connections throughout our group.

3)With full participation, engage in proactive activities to preempt and prevent problems through continuous education, as well as thoroughgoing standardization and compliance.

All employees of the Sumitomo Rubber Group shall understand and practice these Quality Policies while striving to ensure the full implementation and operation of our Quality Management System.

Enacted: September 10, 1999

Revised: March 28, 2022

Satoru Yamamoto

President & Representative Director

Sumitomo Rubber Industries, Ltd.

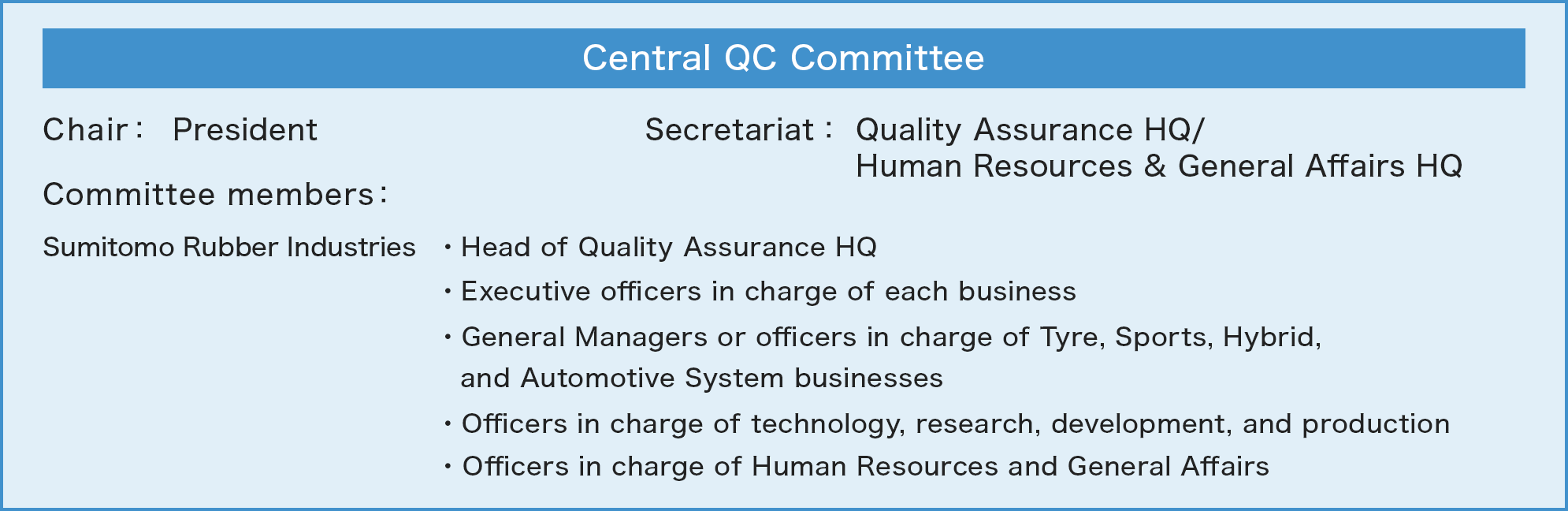

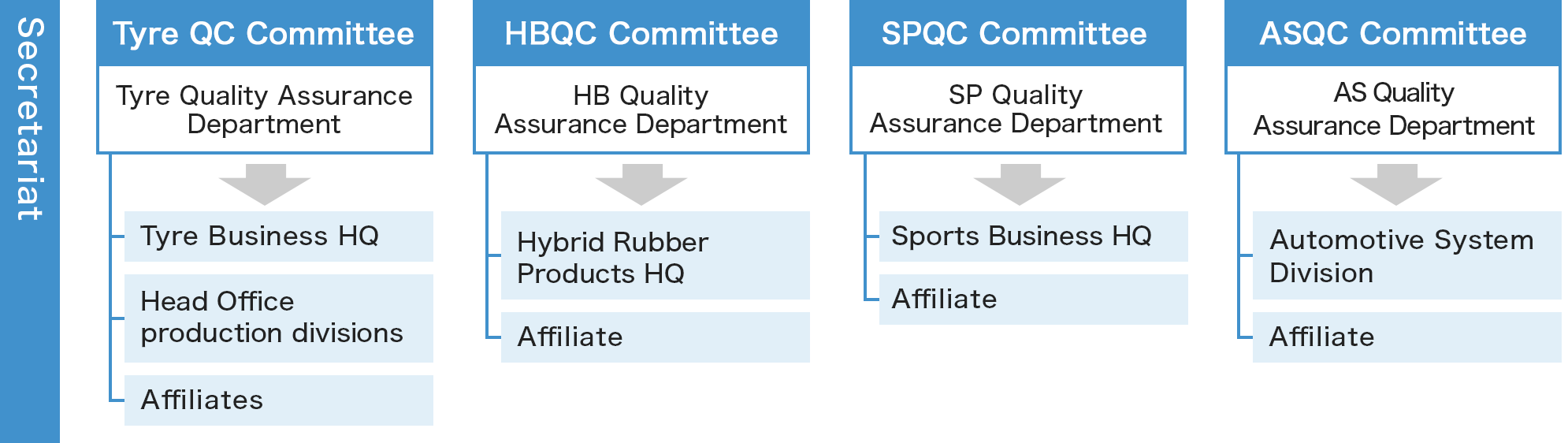

The Sumitomo Rubber Group has established a Central QC Committee, chaired by the President, as the highest decision-making body in terms of quality-related policies. The policies decided by the Central QC Committee are implemented globally through QC Committees in each of the four business divisions (Tire, Sports (SP), Hybrid (HB), and Automotive System (AS)), so that our products, services, and solutions are always of good quality, with all business units, ranging from manufacturing, development, and administration to sales divisions, maintaining a high quality of operations.

Furthermore, the effectiveness of these efforts is evaluated by the Central QC Committee and each QC Committee, and a system of internal audits (quality reviews) is in place to identify risks and promote improvements.

Additionally, through acquiring and maintaining certifications such as the ISO 9001 quality management system and the IATF 16949 automotive quality management system standard, we are committed to strengthening quality from the customer’s perspective and pursuing continuous improvement.

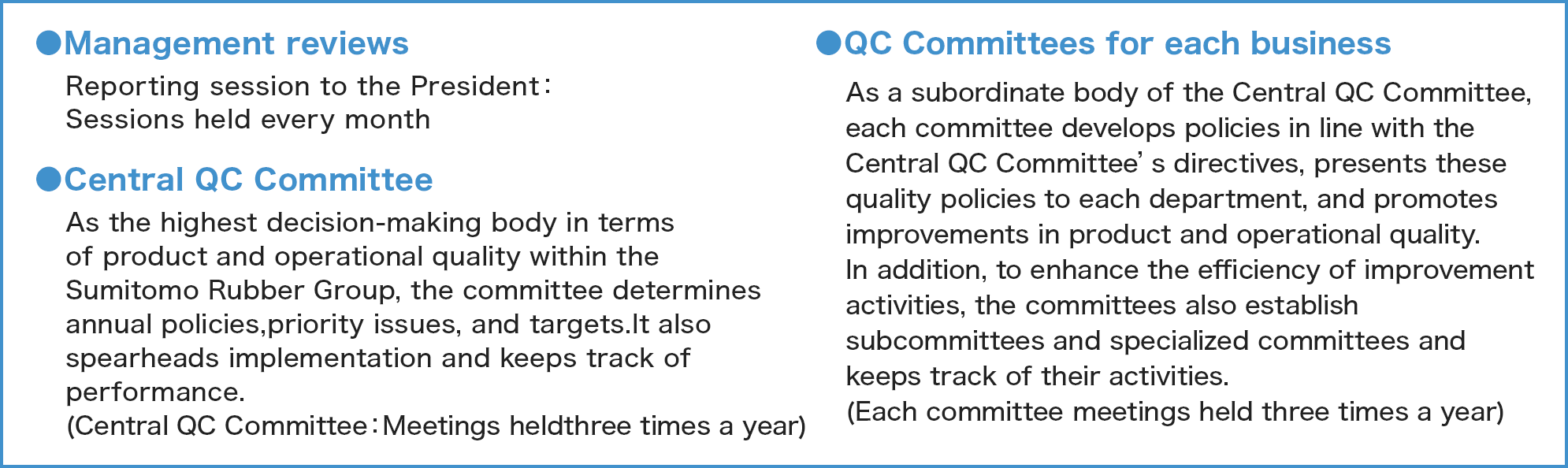

In addition to conducting management reviews at the Central QC Committee and each QC Committee, we have a monthly session for all departments of the Quality Assurance HQ to report the latest quality status to the President, who is also the Chair of the Central QC Committee, every month, enabling top management to provide rapid feedback throughout the company.

As the highest authority overseeing the quality of products, services, solutions, and business operations within the Sumitomo Rubber Group, the committee determines annual policies, priority issues, and targets. It also spearheads implementation and keeps track of performance.

As a subordinate organization of the Central QC Committee, each committee develops policies in line with the Central QC Committee’s directives, presents these quality policies to each department, and promotes improvements in product, service, solution, and operational quality. (Each committee meetings held three times a year)

In addition, to enhance the efficiency of improvement activities, the committees also establish subcommittees and specialized committees (and project teams as necessary) to promote improvement.

Our Group’s quality management system is based on ISO 9001 quality management system standard and IATF 16949 automotive quality management system standard, and we are continuously improving the system to respond to changes in the market environment and further enhance customer satisfaction.

| Business base | Country | Production item | ISO 9001 | IATF 16949 |

|---|---|---|---|---|

| Kobe Head Office | Japan | Tires | ✓ | ✓ |

| Tire puncture emergency repair kits | ✓ | |||

| Marine fenders | ✓ | |||

| Rubber parts for medical applications (medical rubber) |

✓ | |||

| Vibration control damper | ✓ | |||

| Tokyo Head Office | Tires | ✓ | ✓ | |

| Tire puncture emergency repair kits | ✓ | |||

| Tire Technical Center | Tires | ✓ | ✓ | |

| Tire deflation warning systems | ✓ | |||

| Tire puncture emergency repair kits | ✓ | |||

| Tire Proving Grounds: Okayama, Asahikawa, Nayoro | Tires | ✓ | ✓ | |

| Nagoya Factory | Tires | ✓ | ✓ | |

| Shirakawa Factory | Tires | ✓ | ✓ | |

| Miyazaki Factory | Tires | ✓ | ✓ | |

| Izumiotsu Factory | Tires | ✓ | ✓ | |

| Rubber parts for medical applications (medical rubber) |

✓ | |||

| Kakogawa Factory | Tires | ✓ | ||

| Marine fenders | ✓ | |||

| Rubber parts for medical applications (medical rubber) |

✓ | |||

| Vibration control damper | ✓ | |||

| Utsunomiya Office | Tires | ✓ | ✓ | |

| Tokyo Office | Vibration control damper | ✓ | ||

| Nagoya Office (within Nagoya Factory) | Tire puncture emergency repair kits | ✓ | ||

| Hiroshima Office | Tires | ✓ | ✓ | |

| Tire puncture emergency repair kits | ✓ | |||

| SRI Engineering, Ltd. | Tires | ✓ | ✓ | |

| Sumitomo Rubber North America Inc. | U.S.A. | Tires | ✓ | |

| Sumitomo Rubber do Brasil Ltda. | Brazil | Tires | ✓ | ✓ |

| Falken Tyre Europe GmbH | Germany | Tires | ✓ | ✓ |

| Sumitomo Rubber Europe GmbH | Tires | ✓ | ✓ | |

| Dunlop Tech GmbH | Tire puncture emergency repair kits | ✓ | ||

| Sumitomo Rubber AKO Lastik San. Tic.A.Ş. | Turkey | Tires | ✓ | ✓ |

| Sumitomo Rubber South Africa(PTY)Ltd. | South Africa | Tires | ✓ | ✓ |

| Sumitomo Rubber (Changshu) Co.,Ltd. | China | Tires | ✓ | ✓ |

| Sumitomo Rubber (HuNan) Co., Ltd. | Tires | ✓ | ✓ | |

| Sumitomo Rubber (Thailand) Co.,Ltd. | Thailand | Tires | ✓ | ✓ |

| Dunlop Srixon Sports Manufacturing(Thailand)Co., Ltd. | Tennis balls | ✓ | ||

| PT Sumi Rubber Indonesia | Indonesia | Tires | ✓ | ✓ |

| Sumitomo Rubber Singapore Pte. Ltd. | Singapore | Tires | ✓ | ✓ |

| Sumirubber Malaysia Sdn.Bhd. | Malaysia | Rubber gloves | ✓ |

※Standards: ISO 9001: 2015, IATF 16949: 2016

In response to evolving social issues, including the growing impact of climate change, we came to the conclusion that a new policy, one based on long-term perspectives that look to the world of 2050 and beyond, would be essential to our efforts to ensure the sustained growth and development of both our group and society as a whole. In August 2021, we formulated our Long-Term Sustainability Policy, “Driving Our Future Initiatives 2050,” and are working toward our goals. We believe that achieving Driving Our Future Initiatives 2050 will lead to the realization of the Purpose of Our Philosophy, “Through innovation we will create a future of joy and well-being for all.” To this end, we are strengthening our quality foundation throughout the value chain.

Furthermore, the Sumitomo Rubber Group has formulated the long-term corporate strategy R.I.S.E. 2035, and articulated our vision for 2035 as “Continuing to Provide ‘New Experimental Value’ Born from Rubber to Everyone.” Leveraging our two strengths, “rubber and analytical technology” and “brand creation power” to address future social issues and risks, we will continue to deliver attractive new value to customers in various fields such as mobility, sports, healthcare, and daily life, and contribute to the development of a prosperous and sustainable society for the future.

From the perspective of quality reliability, our rubber and analysis technologies, which are one of our strengths, not only enable the development of advanced rubber but also help us avoid quality risks in new areas by elucidating mechanisms through visualization technologies, thereby enhancing the reliability of our value creation process.

In addition, we will strengthen the quality foundation that supports our business strategies for tires, sensing cores, sports, and industrial products, as well as our new lines of business.

This includes promoting preventive measures through the enhancement of quality management systems across the entire value chain, as well as fostering the development of personnel who can adapt to changes in each process.

We are fully committed to ensuring the safety of our products, services, and solutions, which is an essential responsibility we strongly uphold at Sumitomo Rubber Group. We conduct evaluations and verifications using the latest technology and a rigorous preliminary assessment. Before mass production, each quality assurance department strictly reviews the evaluation and verification results for all products, including tires, sensing cores, sports and industrial products, before giving approval to their mass production. Even after mass production begins, we maintain rigorous quality control to ensure the delivery of high-quality, safe products, services, and solutions to our customers.

In the unlikely event that defects or potential defects are discovered in the products, services, or solutions we provide to our customers, we immediately conduct a situation analysis, convene a safety measures meeting as necessary, and promptly implement the required measures. In addition, we have established a system for sharing market information across the entire Group to prevent recurrence and thoroughly implement risk countermeasures.

Based on our corporate philosophy of contributing to the sustainable development of society, we will continue to prioritize providing safe and attractive products, services, and solutions that meet customer needs in compliance with laws and regulations.

As part of our efforts to achieve the annual targets set out in our Long-Term Sustainability Policy, “Driving Our Future Initiatives 2050,” we are strengthening our quality management system by identifying quality risks across the entire value chain, implementing measures to address them, and standardizing them. In addition, we are reviewing our quality assurance system and making further process improvements as necessary to respond to risks.

As shown in the separately reported results of our “Driving Our Future Initiatives 2050” initiatives, we are progressing as planned.

In addition, we are implementing change point training and company-wide quality training to strengthen human resource development that supports the quality of each process. Furthermore, we provide thorough quality training to new managers to promote the development of people who are adaptable to change in both management and practical aspects, enabling them to respond to changes inside and outside the company.

The Sumitomo Rubber Group continuously monitors and improves the quality of raw materials and outsourced products through systematic quality audits, quality issue correction activities, and partnership building with raw material suppliers and contractors in the manufacture of products for the tire, sports, hybrid (industrial products), and automotive systems businesses. By ensuring a reliable supply of raw materials and outsourced products that meet the Group’s quality requirements, we are working to maintain the stability of our manufacturing processes and product quality, and to provide our customers with sustainable products on a stable basis. In addition, given recent global events and a changing external environment, we have become increasingly concerned about maintaining raw material quality. So, having conducted careful evaluations and assessments from the perspective of BCP, we are promoting diversification of the regions from which we source raw materials and externally procured products, selecting new suppliers, and developing sustainable raw materials. We are also making even more of an effort to improve the quality of raw materials and externally procured products, while improving our internal environment by enhancing quality monitoring through interdepartmental and inter-site cooperation.

Through these initiatives, we will contribute to the realization of sustainable societies by providing products that give our customers peace of mind, enhancing the mass production and quality stability of sustainable raw materials and outsourced products, and improving the reliability of our supply chain management.

To ensure the successful implementation of our Long-Term Sustainability Policy, “Driving Our Future Initiatives 2050,” and our long-term corporate strategy, “R.I.S.E. 2035,” which aims “Continuing to Provide ‘New Experimental Value’ Born from Rubber to Everyone,” it is essential to develop a quality management system and nurture human resources who can support quality in all processes. It is especially important to develop people who are adaptable to change while remaining faithful to the fundamentals during significant transformation.

Based on our corporate philosophy of contributing to developing a sustainable society, Sumitomo Rubber Group is creating people who can implement the policy of “Uniting our diverse strengths, growing together, driving and thriving on change with action and quality that always puts the customer first,” as stated in our Quality Policy.

As part of our efforts to develop human resources who can support the quality, we are promoting the cultivation of people who are faithful to the fundamentals and adaptable to change from both a management and a practical perspective. This includes implementing quality education for management (promotees and those scheduled to be assigned overseas) that provides for front-loading for the establishment of reliable quality, and conducting company-wide quality education to raise the quality awareness (quality-first thinking and culture transmission) of all employees, including new hires, by thoroughly instilling the fundamentals.

Additionally, through annual quality improvement activities and education based on past issues, we are fostering a deeper understanding of the quality management system and developing human resources who can implement the system.

In addition to company-wide quality training and annual improvement activities, we have designated November as “Quality Month” to raise quality awareness among employees. During this month, we hold “QC presentation meetings” at Group business bases at home and abroad while soliciting QC slogans and commending excellent submissions. Moreover, the Quality Forum is held at our Kobe Head Office to share and award best practices of product quality and operational quality improvements in each department and each office.

One of the examples introduced in this Quality Forum is MIRAIE, a product of our industrial products business (vibration control damper business), which was developed by establishing reliable quality management throughout the entire value chain. This product represents our contribution to a sustainable society as it has saved customers’ lives and property in times of large-scale earthquakes. We instill in all employees that “business is built on quality.”

We will continue to enhance the quality awareness of all employees through these activities, share information related to customer and market needs, and pursue continuous quality improvement from the customer’s perspective. This will enhance customer satisfaction and advance the creation of a sustainable society.