To pursue the happiness of all Sumitomo Rubber Group employees and create a safe, healthy, and comfortable workplace, the Sumitomo Rubber Group is acting in close collaboration with the labor union under the slogan, “Occupational safety and health must be prioritized over anything else.” Through good communication between labor and management, we promote the continuous improvement of occupational safety and health activities, respond to changes in the environment, and fulfill our corporate social mission with the participation of all employees.

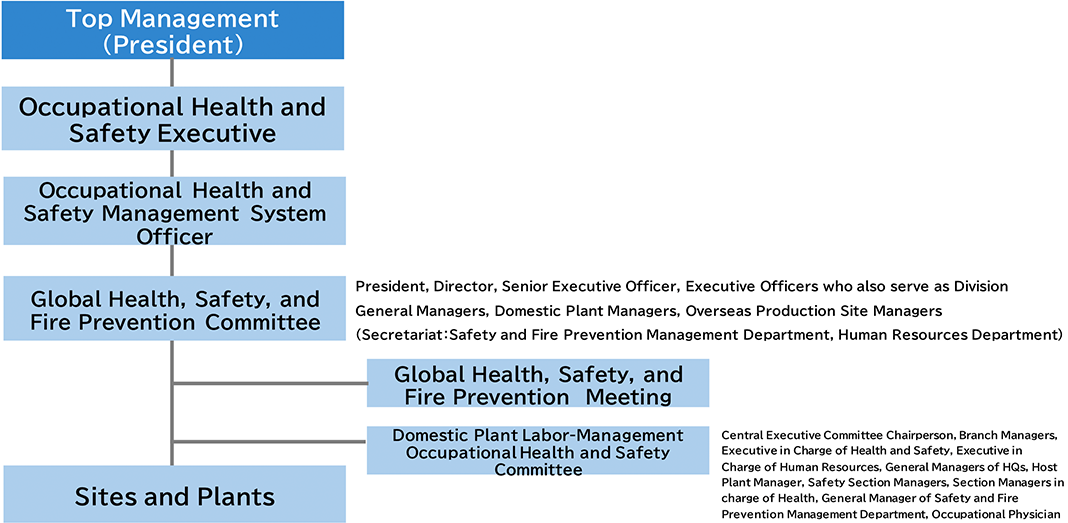

The Global Safety, Health and Fire Prevention Committee has established the safety and health activity guidelines for our corporate group.

1.Building safe equipment

•We will strengthen risk assessments and promote safety-first design practices.

•We will clarify the roles of safety devices, promote their standardization and deployment, and provide a safe working environment.

•We reduce risks by conducting regular inspections and maintenance of equipment.

•We are committed to creating a low-strain work environment where diverse workers can perform comfortably.

2.Fostering safety- and health-conscious personnel

•We conduct training programs to raise awareness, aiming to “foster safety-conscious individuals”.

•We provide continuous training and development to enhance the effectiveness of risk assessments.

•By fostering an open and transparent workplace culture, we listen to employees' voices and drive continuous improvement.

•We establish support systems for employee stress and health issues to improve the working environment.

3.Enhancing the management system

•We comply with all relevant occupational safety and health laws and respond appropriately to external requirements.

•We promote the thorough implementation and expansion of occupational health and safety management based on international standards such as ISO 45001.

•We continuously improve our activities through steady implementation at each site and enhanced collaboration across locations.

•We introduce KPIs that reflect the actual status of activities and conduct regular monitoring.

Under the slogan "Safety and health take precedence over everything," we promote activities centered on creating safe equipment and fostering safety-minded personnel, while also advancing the development of a healthy and comfortable hygienic environment to support these efforts.

The Group aims to achieve zero occupational accidents and create safe facilities and safety-oriented human resources, which we consider important factors. We focus on fostering a safety culture in addition to skills and knowledge, and implement safety and health initiatives through rank-based training and workplace communication.

With regard to skills and knowledge for safe facilities, we are focusing on training risk assessment managers. The aim is to conduct appropriate risk assessments, eliminate sources of danger in equipment and work operations, and enhance intrinsic safety. In 2024, we successfully trained more people than our target number as risk assessment managers.

To develop safety-oriented human resources, we are raising individual safety-oriented Key Performance Indicators (KPIs) and creating workplaces where everyone can easily voice their opinions on safety. Individual KPIs are characterized by the ability to objectively view one’s behavioral characteristics and the ability of managers and supervisors to understand the strengths and weaknesses of each workplace.

We are working to create workplaces where safety rules are observed in all circumstances and to foster a safety culture.

We will promote initiatives to link safety & health and fire-prevention activities to foster a safety culture by thoroughly implementing the PDCA cycle at each tier.

We will establish a Safety & Health and Fire-Prevention Committee to strengthen dialogue with management and management review functions.

We will improve the level of knowledge at each base of operations through dialogue, information sharing, and ongoing training based on safety & health, and fire-prevention activity plans.

We will promote the creation of workplaces where management visits the front lines, stays close to the front lines, and listens to the voices of front-line employees.

The Sumitomo Rubber Group had previously acquired certification under OHSAS 18001, an international standard for occupational health and safety management system.

In 2018, our business bases began upgrading their OHSAS 18001 certification to that based on ISO 45001 in a phased manner. With the South Africa Factory having completed this transition in September 2021, all certified factories have successfully shifted to ISO 45001. Currently, 12 factories, which account for 50% of the 24 factories run by the Group, maintain certification under ISO 45001.

| List of Business Bases Certified under ISO 45001 | Certified Sites |

|---|---|

| December 2018 | Changshu Factory, China |

| November 2019 | Miyazaki Factory |

| November 2019 | Izumiotsu Factory |

| November 2019 | Turkey Factory |

| November 2019 | Brazil Factory |

| February 2020 | Hunan Factory, China |

| June 2020 | Shirakawa Factory |

| June 2020 | Nagoya Factory |

| October 2020 | Thailand Factory (natural rubber processing) |

| November 2020 | Indonesia Factory |

| January 2021 | Thailand Factory |

| September 2021 | South Africa Factory |

To protect the safety and health of employees, we continuously strive to create a safe operational environment in which everyone can take on their tasks with confidence. In fiscal 2024, we continued to improve the operational environment by addressing issues associated with heat, noise, dust, organic solvents, and other factors as part of efforts to realize a more pleasant workplace environment. In fiscal 2025, we will maintain these efforts, placing emphasis on implementing countermeasures against heat.

Sumitomo Rubber Industries does not currently manufacture any products incorporating asbestos. Furthermore, at the end of 2006, the Company completed the inspection of spray-applied materials used in its buildings as well as the analysis of mineral-based raw materials, confirming the absence of asbestos-related issues. However, it was confirmed that, among its workforce, a total of 13 people have passed away due to lung cancer, while 54 individuals have succumbed to a mesothelial tumor, with all these cases publicly recognized as occupational fatalities (* in another case, an application for such recognition has been submitted) as of July 2024.

On April 1, 2007, the Company established a special compensation program for individuals who have suffered health damage due to asbestos. Thus, we voluntarily provide special compensation to those whose diseases are recognized as being attributable to occupational exposure to asbestos. Moreover, since March 2007, we have striven to reach out to retirees to encourage them to undergo health checkups aimed at diagnosing the presence of asbestos-related diseases. As a result, 41 people have applied to become holders of a government-issued medical certificate for asbestos-related health damage.

Looking ahead, we will proactively respond to consultation requests from employees.

| 2024 targets |

|

|---|---|

| 2024 results |

|

| 2025 targets |

1.Safety and health policy

2.Targets

|

| Medium- to long-term targets | Enhance safety and fire-prevention knowledge, build a workplace where employees can protect their colleagues, and realize ESG management where employees can work peacefully |

To maintain “zero” serious accidents, we will focus on accidents that could lead to serious accidents and take measures to prevent them.

We will continue to promote activities to reduce individual variation in safety-first KPIs and raise safety awareness among all employees.

We will conduct education to increase awareness of potential hazards, cultivate personnel capable of identifying risks, and work to prevent accidents before they occur.

The Sumitomo Rubber Group aims to eliminate occupational accidents. To this end, we consider nurturing safety-oriented human resources a matter of utmost importance. Therefore, we focus on risk assessment education and emphasize the development of risk assessment managers.

Furthermore, we provide special education and hands-on experiential education, and engage in regular safety and health education activities while confirming the degree of mastery of relevant skills and knowledge.

We hold a twice-yearly company-wide Occupational Safety & Health and Fire-Prevention Convention attended by internal directors, including the Representative Director and President, as well as all executive officers and heads of all manufacturing sites, with the aim of ensuring that information regarding safety, fire prevention, and employee health is shared among the entire workforce. Through this event, the Group gathers reports on targets for and the progress status in various measures related to safety and health, as well as health and productivity management. By doing so, we endeavor to mitigate the level of risks affecting safely, fire prevention, and employee health.

Since fiscal 2007, the Sumitomo Rubber Group has conducted fire-prevention audits with the aim of identifying and addressing fire risks at each site. As part of our global efforts, including overseas bases, each site has set up a Fire Prevention Committees and conduct annual voluntary audits to check all fire prevention activities, striving to mitigate fire risks on a day-to-day basis. During these voluntary fire-prevention audits, we not only check whether each site has an organizational structure in place to carry out fire-prevention activities, but also ask questions on-site to assess the fire-prevention awareness of each employee. By checking their understanding of fire risks and the mechanisms for engaging in fire-prevention activities, we carefully confirm that there are no missing perspectives or elements in their activities. We will continue to conduct comprehensive inspections of fire-prevention activities through audits, mitigate fire risks, and expand effective activities at individual sites to other sites, taking on the challenge of achieving minor or zero fire.