Product and Technological Development Undertaken by Tire, Sports and Industrial Products Businesses

Next [Pursuit of eco-friendly products and services]

- E ●

- S -

- G -

- Developing Run-Flat Tires Designed Support Safe Driving

- Realizing Airless Tires Free of Puncture Risk or the Need for Air Pressure Management

- Developing Fuel-Efficient Tires

- Creating Tires Completely Free of Fossil Resources

- Promoting the Use of Sustainable Raw Materials

- Developing Biomass Raw Materials

- Developing a Novel Biopolymer

- Initiatives to Reduce the Use of Plastics

- Developing Vibration Control Dampers That Help Enhance Earthquake Resistance

- Launch of Ki kara Umareta Gloves Made of Eco-Friendly Natural Rubber for Household Use

- Release of Ki kara Umareta Gloves: Simple Color Edition

- Initiatives to Counter the Microplastics Problem

Developing Run-Flat Tires Designed Support Safe Driving

- The Sumitomo Rubber Group

As part of efforts to make driving even safer, Sumitomo Rubber Industries is striving to develop and popularize run-flat tires capable of helping vehicles keep running at a certain speed for some distance*1 even after entirely losing air pressure during driving.

Specifically, we have released DUNLOP SP SPORT MAXX 050NEO, a premium run-flat tire series, in Japan. This series boasts superiority in driving comfort, environmental friendliness*2 and safety performance thanks to the utilization of our proprietary NEO-T01 next-generation production method as well as 4D NANO DESIGN material development technology. Also, FALKEN AZENIS FK510RUNFLAT made using similar technologies is currently available in Japan, Europe and elsewhere.

We also market conventionally manufactured run-flat tires. These include DUNLOP SP SPORT MAXX 050+, ZIEX ZE914 ECORUN RUNFLAT and EUROWINTER HS449 RUNFLAT. We will strive to enhance the lineup of run-flat tires to make driving even safer for all customers.

*1The ability to enable the vehicle to drive at a speed of 80km/h for a distance of 80km is a requisite for run-flat tires.

*2In terms of reductions in tire weight.

Realizing Airless Tires Free of Puncture Risk or the Need for Air Pressure Management

- The Sumitomo Rubber Group

Currently, Sumitomo Rubber Industries is engaged in the development of GYROBLADE airless tire technology, which is a component of SMART TYRE CONCEPT.

The use of GYROBLADE technology is expected to make it possible to create a tire free of puncture risk or any need for air pressure management. In addition to enhancing driving safety, such airless tires would eliminate the need for carrying a spare tire, thereby contributing to resource and energy savings. On the other hand, airless tires must meet the same requirements for fuel efficiency as pneumatic tires. With this in mind, we have consolidated leading-edge Sumitomo Rubber Industries technologies to develop airless tires, for example, adopting the tread rubber used for fuel-efficient pneumatic tires and leveraging NEO-T01, a next-generation production method backed by ultra-high-precision tire manufacturing technology.

We will continue to pursue R&D activities focused on creating tires that transcend conventional concepts and the early commercialization of GYROBLADE technology.

Developing Fuel-Efficient Tires

- The Sumitomo Rubber Group

Based on the SMART TYRE CONCEPT, our Performance Sustaining Technology has been incorporated into the “VEURO VE304” premium comfort tire. This concept also led to the release of the flagship “ENASAVE NEXT III” fuel-efficient tire. The release of these tires helped us step up our sales expansion efforts.

Both of these tires also incorporate a hydrogenated polymer that helps prevent a decline in wet grip performance while contributing to superior wear resistance.

The release of the “VEURO VE304” was achieved via the establishment of a technology that makes it possible to incorporate this polymer into products designed for large volume sales. We therefore consider the “VEURO VE304” a testament to our remarkable technological advancements.

The “ENASAVE NEXT III,” on the other hand, incorporates cellulose nanofiber to achieve driving comfort and steering stability. This product is the first in the world to incorporate cellulose nanofiber, a biomass material boasting environmental friendliness. From the viewpoint of sustainability, we believe that our success in utilizing biomass as a tire material is a matter of great significance.

We have received robust customer reviews for these products.

In addition, the “VEURO VE304” was named a Grand Prix winner under the DAILY AUTOMOTIVE NEWS Car Parts Awards 2020 program, while the “ENASAVE NEXT III” was chosen to receive multiple awards under the Eco-Pro Award program, the Super Parts Manufacturer Award program and the Energy Conservation Grand Prize program. As such, our products are similarly lauded by external organizations.

Topics

DUNLOP “e. SPORT MAXX,” the First Replacement Tires Released by Sumitomo Rubber Industries for EVs

To increase the driving distance achievable by an EV with one round of charging, it is necessary to reduce rolling resistance and curb energy consumption. Our “e. SPORT MAXX” has been made using our proprietary material development technologies, which have enabled the unique composition of the tire’s rubber. Thanks to these technologies, this product achieved the highest level of fuel (energy) efficiency among our products while also realizing greatly improved wet grip performance and steering stability. Furthermore, we successfully decreased the weight of the tire itself, with the aim of saving resources used and contributing to the reduction of environmental burden. Not only that, the “e. SPORT MAXX” features on its side walls a logomark printed using “Nano Black,” a proprietary black pigment application technology, as we pursued a design that makes it stand out.

Creating Tires Completely Free of Fossil Resources

- The Sumitomo Rubber Group

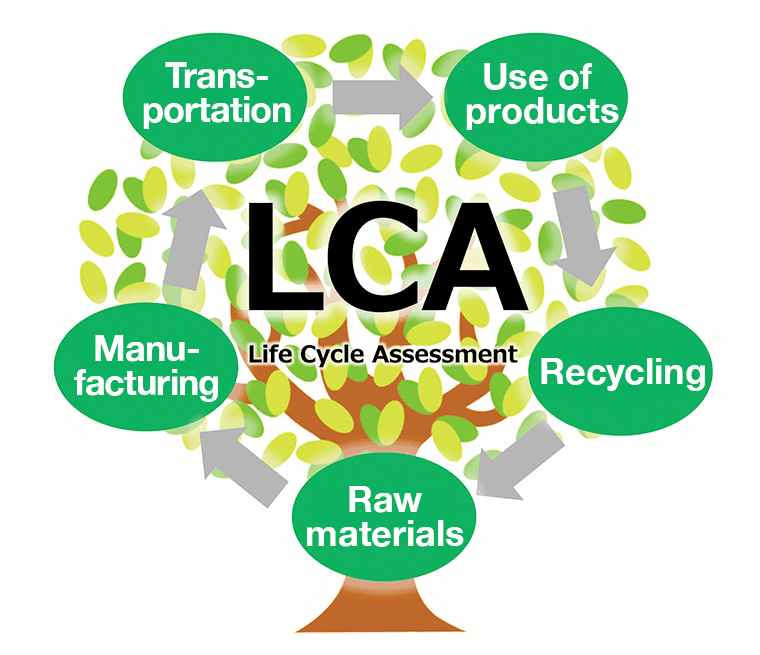

Sumitomo Rubber Industries has striven to realize SMART TYRE CONCEPT, which informs the development of innovative tires and peripheral services. For example, in the course of promoting product development, we utilize Performance Sustaining Technology, which curbs deterioration in tire performance due to tire wear or aging and sustainably preserves the robust performance they boasted when fresh off the manufacturing line. We also incorporate the Tire Life Cycle Assessment (LCA), which aims to contribute to the realization of a recycling-oriented society via the enhancement of tires’ environmental performance throughout their entire product life cycles. The former technology is best exemplified by DUNLOP ENASAVE NEXT III, with the pace of deterioration in its wet grip performance being half of that of conventional tires. Also, we became the first in the world to incorporate cellulose nanofiber, an advanced biomass material promoted by the Japanese government as a priority industry initiative, for use in tire rubber to create ENASAVE NEXT III. This product was chosen to receive an AAA-a rating—the highest possible—under Japan’s tire labeling system. Furthermore, ENASAVE NEXT III is capable of contributing to the reduction of environmental burden from the perspective of the LCA.

Looking ahead, we will strive to raise the environmental performance of our products throughout their entire life cycles even as we promote the development of products capable of contributing to the realization of a recycling-oriented society.

*Based on a survey undertaken by Sumitomo Rubber Industries, quoted from a news release

Promoting the Use of Sustainable Raw Materials

- The Sumitomo Rubber Group

In line with our Long-Term Sustainability Policy “Driving Our Future Challenge 2050,” we aim to pursue the creation of “a future of joy and well-being for all” through the practice of ESG management. Moreover, as part of our environmental initiatives, we have formulated “TOWANOWA,” a unique business concept that supports the circular economy. Based on this concept, we aim to reduce the volume of CO2 emissions and realize sustainability along our entire value chain, including material development and the procurement process. To this end, we have set targets for increasing the sustainable raw material content of our tires at 40% by 2030 and 100% by 2050.

In March 2023, we developed new tires for racing use. These tires are manufactured using biomass and recycled raw materials, which together account for 38% of raw materials used, and are sold under the Dunlop brand in the motor sports field—the front line of tire development. To create these tires, we utilized natural rubber and naturally derived raw materials as well as materials recovered from recycled steel. The resulting tires have a sustainable raw material content much greater than that found in conventional racing tires. Looking ahead, we will update and finely tune these tires to enhance their performance as we aim to make them available for actual racing use by the end of 2024.

In addition, from 2024 onward we will release replacement tires with high sustainable raw material content for commercial use.

Developing Biomass Raw Materials

- The Sumitomo Rubber Group

Having completed “ENASAVE 100”—the world’s first 100% fossil resource-free tire—in 2013, we have endeavored to upgrade our technological capabilities to create advanced tires by realizing the potential of naturally derived ingredients as materials supporting superior tire performance. We have thus striven to incorporate biomass raw materials through the use of proprietary Sumitomo Rubber Industries technologies accumulated over the course of developing the aforementioned product.

In August 2016, we released “WINTER MAXX 02,” the first tire created by Sumitomo Rubber Industries via the incorporation of “Super Cohesion Nano Fit Rubber” made using Liquid Farnesene Rubber. A newly developed biomass raw material aimed at enhancing flexibility, Liquid Farnesene Rubber boasts superior functions that curb the hardening of tires over time. The use of this raw material has thus made it possible to maintain robust on-ice driving performance over a long period of time. Liquid Farnesene Rubber is also used in WINTER MAXX 03, a successor product released in August 2020.

Meanwhile, “ENASAVE NEXT III,” which was released in December 2019, incorporates cellulose nanofiber, thereby achieving driving comfort and steering stability. This product was the first tire in the world to incorporate cellulose nanofiber. From the viewpoint of sustainability, we also believe that our success in utilizing biomass as a tire material is a matter of great significance.

In January 2022, we released “SP SPORT MAXX 060+,” which is our fist tire made using our “Sustainable Silica Dispersion Agent.”

Developing a Novel Biopolymer

- The Sumitomo Rubber Group

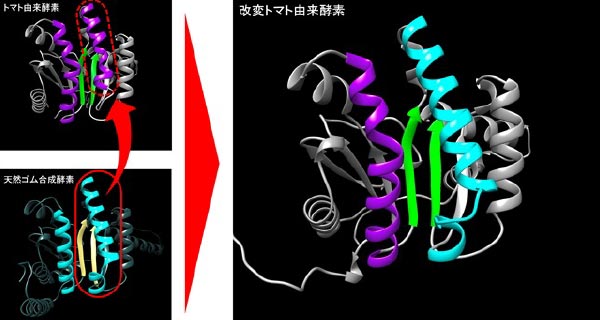

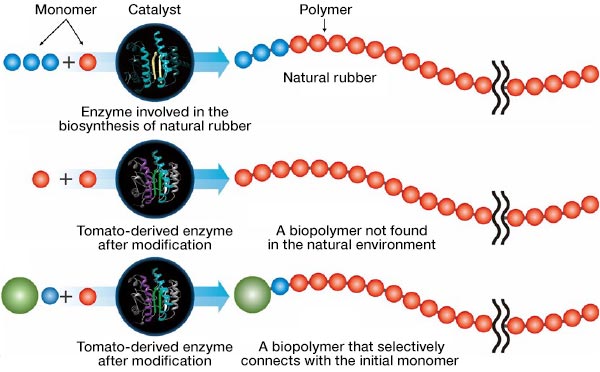

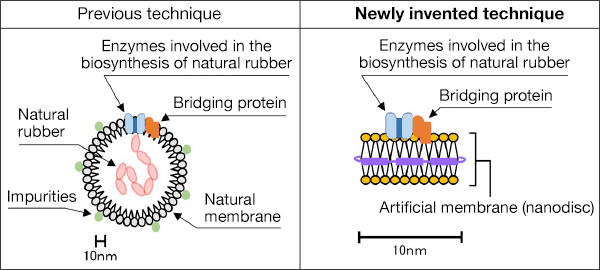

In line with the Long-Term Sustainability Policy, we are engaged in initiatives to make natural rubber a sustainable resource. In 2016, we publicly announced the discovery of enzymes involved in the biosynthesis of natural rubber, a finding from our R&D activities as part of the aforementioned initiatives. Since then, we have been engaged in research aimed at developing biopolymers via the use of enzymes through joint research involving Tohoku University, Kanazawa University, Saitama University and RIKEN. To date, this joint research has resulted in the creation of a new enzyme evaluation technique using artificial membranes, the modification of enzyme properties based on data regarding enzyme structure and the successful development of a novel biopolymer via the use of modified enzymes.

These accomplishments are highly rated by external organizations. For example, the Company was chosen to receive “Materials Innovation of the Year” and “R&D Breakthrough of the Year” awards at “Tire Technology Expo 2023” held on March 21 through 23, 2023 in Hanover, Germany, in recognition of its accomplishments in cutting-edge material research in the field of biopolymer synthesis and the breakthrough achieved via the invention of a new enzyme evaluation technique, respectively.

Going forward, we will continue pursuing these R&D themes associated with enzymes involved in the biosynthesis of natural rubber. This will, in turn, enable us to produce natural rubber that helps enhance tire performance even as we play our part in ensuring the sustainable supply of natural rubber while delivering products with smaller environmental footprints. In these ways, we will contribute to the sustainable development of society.

Initiatives to Reduce the Use of Plastics

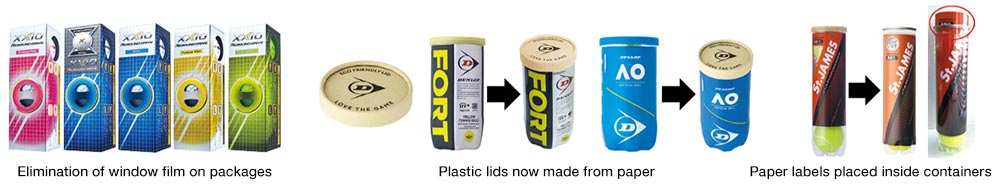

We have identified “Reducing Plastic Usage” as part of measures stipulated under the Long-Term Sustainability Policy: “Driving Our Future Challenge 2050.” In this regard, our Sports Business strives is moving forward with a 50% reduction in the amount of plastic used for product packaging and other materials by 2030 compared to the 2019 level.

For golf balls released in the fall of 2021 and thereafter, window film on packaging is being phased out. In addition, from 2023, the plastic lids of PET packaging tubes for DUNLOP AUSTRALIAN OPEN and DUNLOP FORT tennis balls sold domestically will be replaced with paper ones. Plastic lids for the St. JAMES brand training balls and other products were eliminated and the labels were replaced with paper ones that slip inside the containers.

These initiatives are expected to reduce domestic plastic usage by approximately 20 tons per year. After 2024, we plan to take similar measures in other countries and regions.

Developing Vibration Control Dampers That Help Enhance Earthquake Resistance

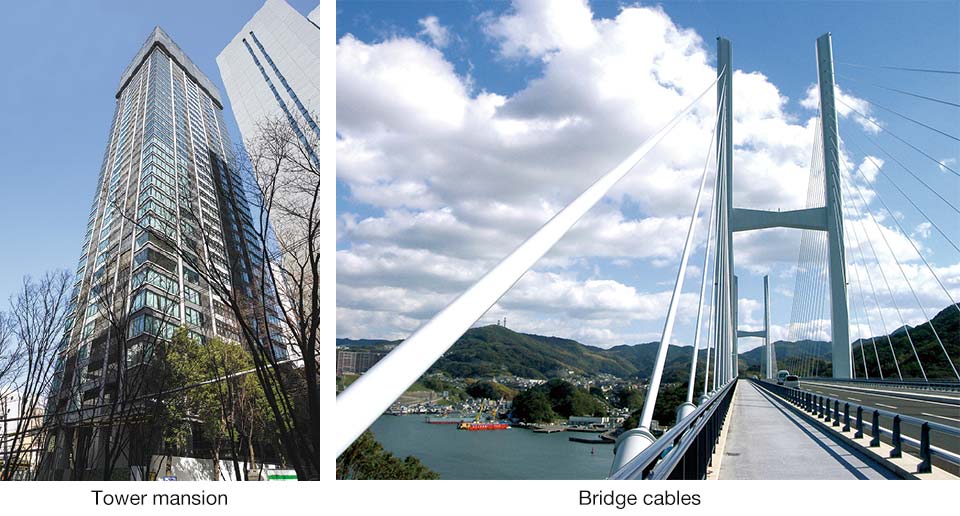

High damping rubber produced by Sumitomo Rubber Industries is capable of reducing diverse forms of vibration, ranging from the small vibrations caused by wind to severe seismic jolts, through the conversion of the kinetic energy of vibrations to thermal energy.

Because of this feature, our vibration control dampers are widely used in buildings and structures in diverse sizes, including detached housing and high-rise buildings as well as large bridge cables and beams.

Examples of Buildings That Use Vibration Control Dampers

Topics

Historic Building Preservation Project—Vibration Dampers Installed in Hokkedo Hall of Shoshazan Engyoji Temple for Vibration Control Damper MIRAIE’s 10th Anniversary

The Sumitomo Rubber Group installed vibration control dampers in December 2022 in the Hokkedo Hall of Shoshazan Engyoji Temple, which boasts more than 1,000 years of history, in Himeji City, Hyogo Prefecture.

The dampers used are made of high damping rubber and symbolize the apex of our unique vibration control technology. To date, they have been utilized in the seismic retrofitting of Higashi Honganji Temple, one of the largest wooden structures in the world, as well as the castle tower at Kumamoto Castle. The dampers were installed in the Hokkedo Hall of Shoshazan Engyoji Temple as the first step of the Historic Building Preservation Project, which commemorates the 10th anniversary of the launch of MIRAIE Vibration Control Units for Detached Housing, which use the same high-damping rubber.

From this installation on, we will continue to promote measures to safeguard both new and existing structures from earthquakes.

Launch of Ki kara Umareta Gloves Made of Eco-Friendly Natural Rubber for Household Use

- Group companies

Dunlop Home Products markets “Ki kara Umareta Gloves” (literally, “made from trees”) made of eco-friendly natural rubber for household use. To accommodate diverse needs, these gloves comprise three types: “Rich-ne,” which incorporates Selatex (hypoallergenic natural rubber created using proprietary Sumitomo Rubber Industries technologies); “Good-ne” standard type; and “Pretty-ne” designed specifically to fit women’s hands.

In addition, this subsidiary is engaged in the “1 PAIR for 1 LOVE” social contribution activities through which it donates funds for supporting tree planting in Malaysia and the Pink Ribbon Campaign aimed at raising the public awareness of breast cancer in Japan to help protect women’s health, with the volume of donations determined based on the number of “Ki kara Umareta Gloves” sold. These donations are also used to support initiatives aimed at encouraging men to play greater roles in housekeeping and child rearing as well as people’s participation in activities undertaken by the Japanese Red Cross Society. In fiscal 2022, a total of \3,010,000 was donated. In the same fiscal year, 2,400 trees were planted in Malaysia, and the cumulative total number of trees planted since the commencement of tree planting amounted to 26,400. We will continue striving to restore the native forest environment in which orangutans live.

Click here for the detail of “Ki kara Umareta Gloves” (Japanese only) ![]()

Release of Ki kara Umareta Gloves: Simple Color Edition

Ki kara Umareta Gloves: Simple Color Edition are available in two colors, Monotone White and Monotone Black, to easily complement today’s attractive kitchens and water features. The Ki kara Umareta series of gloves are composed of natural rubber, which is gentle on the skin and environmentally friendly as it can be broken down by soil microorganisms and thus returned to nature. The inner surface of the gloves has a cotton flocked lining for comfort. In addition, because of their antibacterial treatment, they adhere to the Food Sanitation Act,* meaning they are hygienic and can be used to safely prepare both meat and fish.

The gloves’ packaging features pictograms (graphic symbols) indicating their functions and features in a simple manner easily understood at a glance. We bring safety, security, and comfort into customers’ lives with our eco-friendly natural rubber gloves that are available in stylish colors, kind to the Earth’s environment and made of soft natural skin-friendly rubber that is comfortable to users’ hands.

*Specifications and Standards for Food, Food Additives, etc. (Ministry of Health and Welfare Notification no.370, 1959).

Click here for details on Simple Color Edition gloves (Japanese only) ![]()

Initiatives to Counter the Microplastics Problem

Artificial turf used in sporting facilities is now considered a possible source of microplastic* dispersion into rivers and the sea as, with use over time, turf fibers break and the rubber chips used as fillers may leak, spreading into the environment. Aware of this possibility, since 2020 Sumitomo Rubber Industries has been engaged in surveys aimed at determining the degree of dispersion with the collaboration of local governments and other bodies in charge of the management of the sports facilities in question. Moreover, we are developing materials and products designed to robustly curb microplastic dispersion while conducting the verification testing of such materials and products.

Products we have developed thus far include barrier materials used in the outer perimeter fences of artificial turf and filtering materials to be installed in drainage conduits. For some of these products, their use as a microplastics countermeasure has been designated by the Ministry of the Environment as a good practice or featured in Guidelines Regarding the Curbing of Microplastic Dispersion from Artificial Turf Facilities issued by Osaka Prefecture in March 2023. Moreover, since June 2022, the planning of countermeasures to curb the dispersion of microplastics from municipal tennis courts with artificial turf incorporating sand has been under way in collaboration with Tama City, Tokyo.

*Small pieces of plastic that have a diameter of no more than 5mm.

The Ministry of the Environment: Good Practices of the Reduction of Micro Plastics (Japanese Only)